In the intricate machinery and processes of manufacturing facilities, even the smallest components...

In the intricate machinery and processes of manufacturing facilities, even the smallest components...

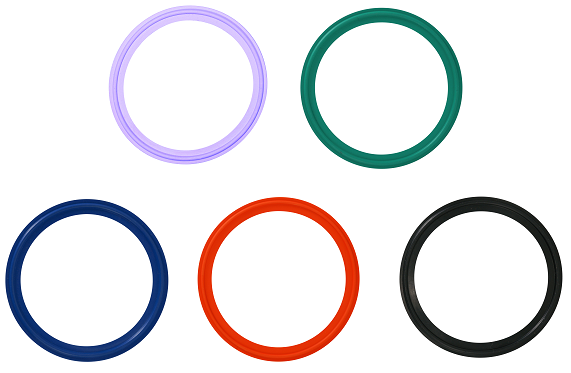

Gaskets play a vital role in various industries, from food and beverage to pharmaceuticals and...

Check valves are essential components in various fluid systems, ensuring the flow of liquids or...

In sanitary applications, where cleanliness and hygiene are the most important elements, selecting...

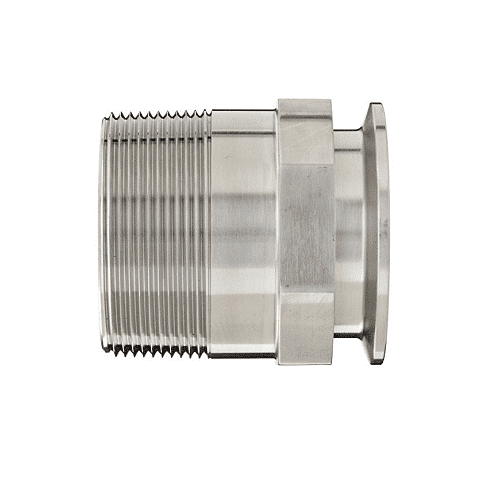

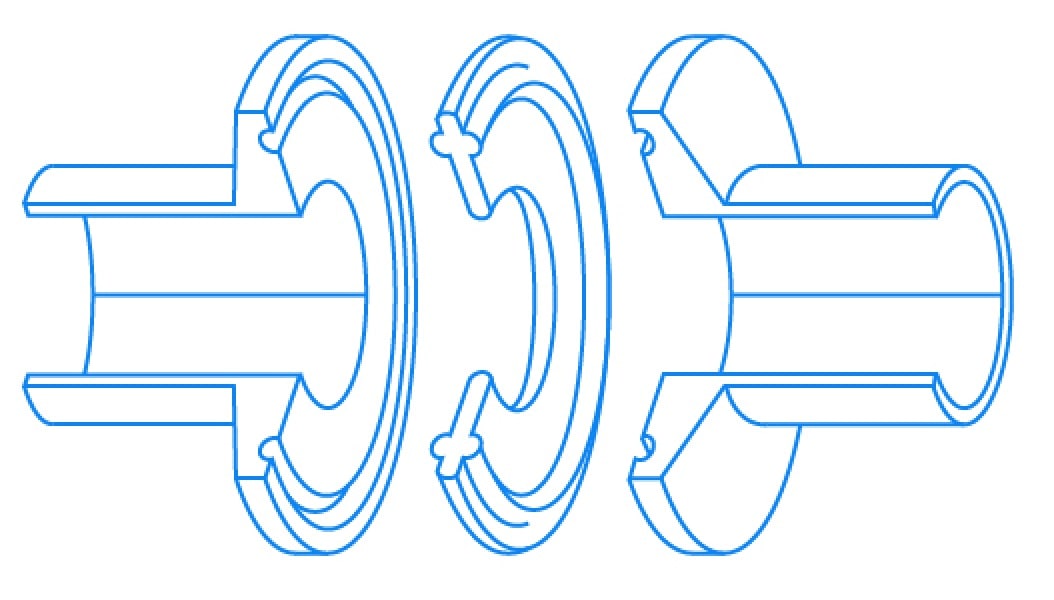

We discuss the similarities, differences, and main uses for some of the most common connection...

Food production and related industries require the right equipment for efficiency, safety, and...

Due to high demand, Sanitary Fittings is now offering replacement parts and service kits for some...

One often-overlooked component that plays a significant role in maintaining hygiene and preventing...

In the industrial hygiene industry, companies across various sectors are continually seeking...

Maintaining a washdown system is essential in industries where cleanliness and hygiene are...

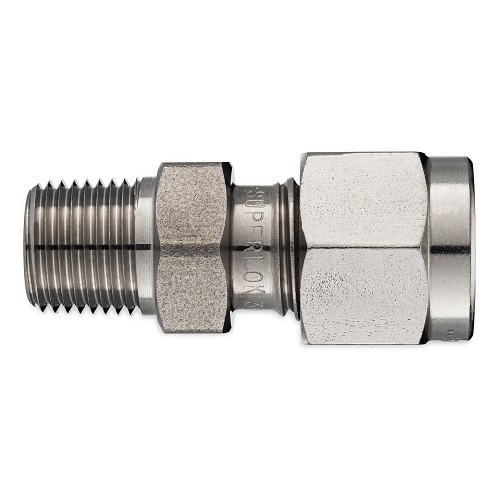

Understanding Sanitary Compression Fittings Sanitary compression fittings are specialized...

The terms pipe, tube, and sanitary tube are often used interchangeably, leading to confusion for...

In industries where cleanliness is non-negotiable, the efficiency and safety of your washdown...

At Sanitary Fittings, we understand that maintaining optimal hygiene and efficiency in...

In manufacturing, maintaining impeccable cleanliness and sanitation is paramount, especially when...

In stainless steel tubing for sanitary applications, precision and quality are two of the most...

In manufacturing, the importance of maintaining hygienic conditions cannot be overstated. Sanitary...

Sanitary food-grade hoses are specialized hoses designed for use in the food and beverage industry...

In various industries, maintaining cleanliness and ensuring optimal hygiene are critical factors...

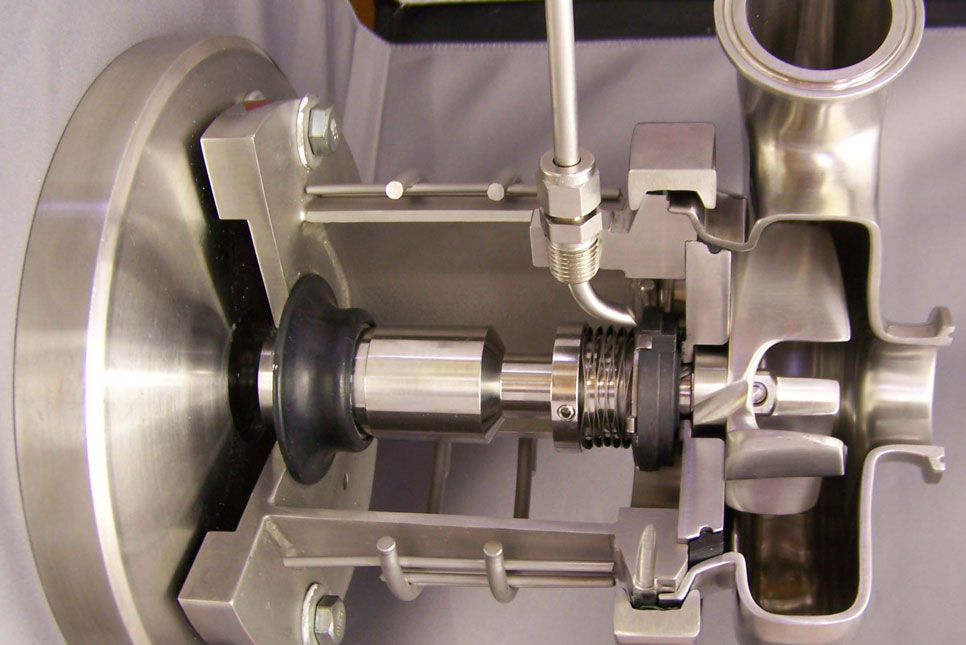

Centrifugal Pump: 6 Common Technical Terms and Their Meanings Centrifugal pumps are one of the...

The Five Types of Hoses Used by Wineries Wineries typically use a variety of hoses to facilitate...

In various industries, fluid and gas systems are an integral part of operations. The reliable and...

Tri-Clamp Gaskets: Ensuring Efficient and Secure Connections In various industries, especially in...

How to Measure NPT Fittings Measuring NPT (National Pipe Taper) threads accurately is crucial for...

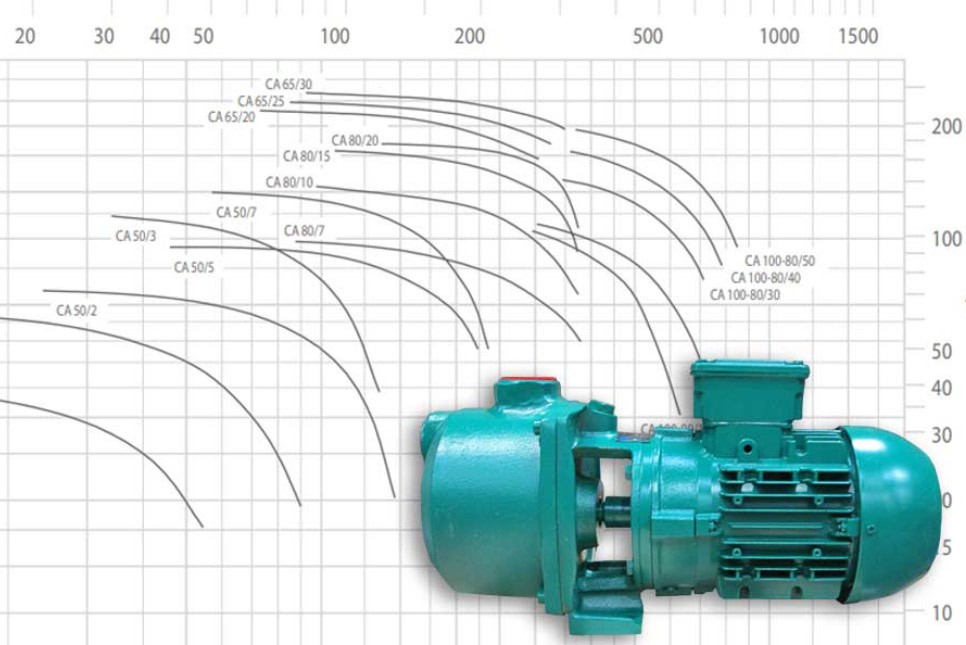

Pump Curve: Expert Tips on How to Read and Use It A pump...

A proper pumping system design requires that your pump be precisely matched to the task. The...

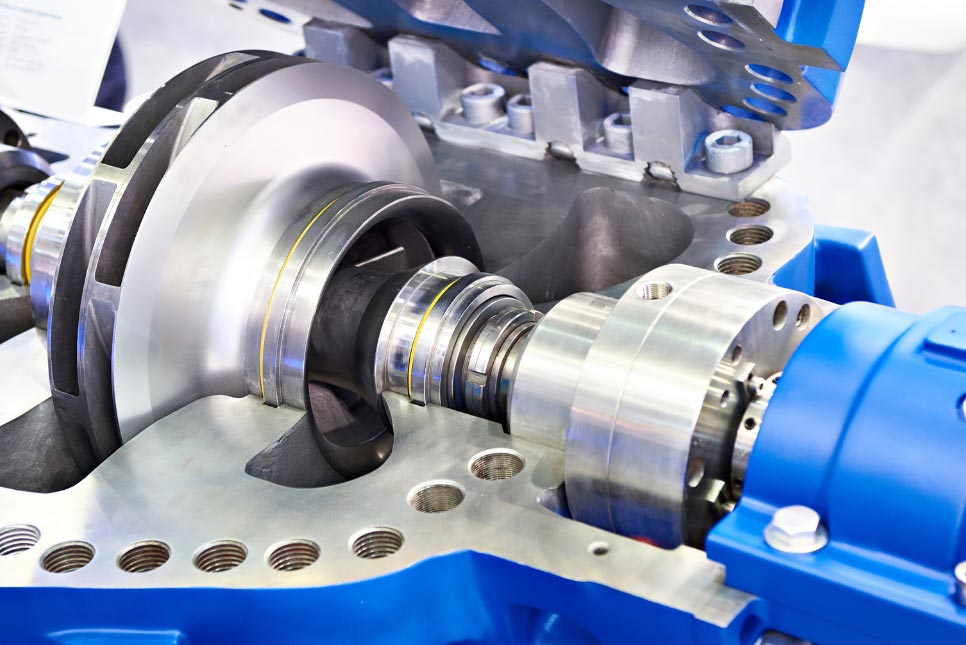

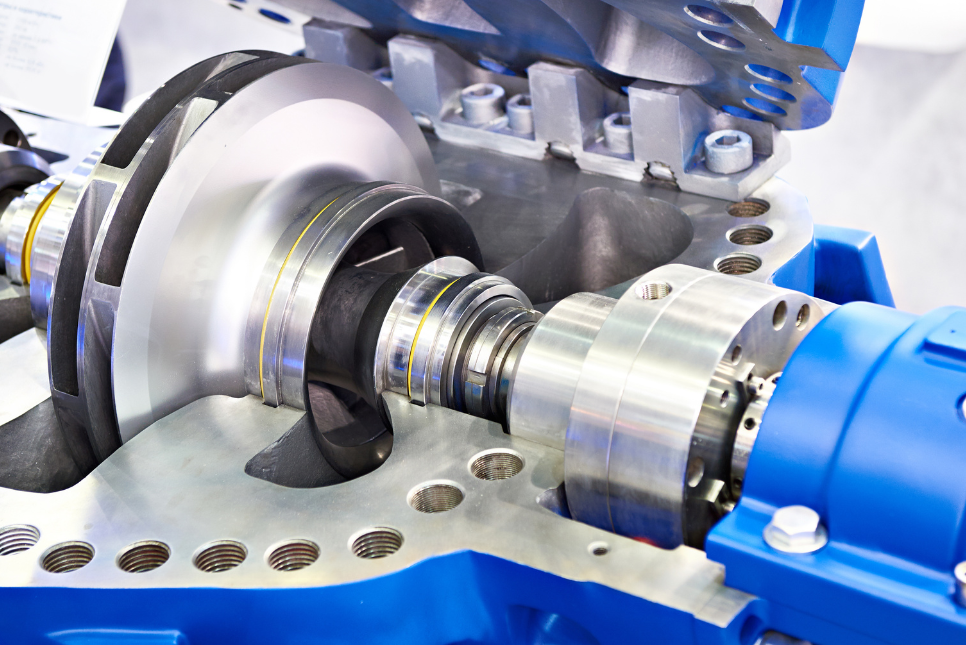

Pump Impellers: 3 Different Types and How to Choose the Right One An impeller is the heart of a...

Sanitary Pump: 3 Tell-Tale Signs Yours Needs Cleaning and How Extremely high standards of plant...

How to Calculate Pump Flow Rate: A Step-by-Step Guide Pump flow rate is a crucial parameter to...

Sanitary Pumps and Pressure: 3 Simple Tips on How They Work...

Pump Head vs Pump Motor: 3 Intriguing Facts You Should Know You may have come across the term...

Pump Size: 4 Practical Tips on How to Size Correctly Sanitary pumps move fluids from one point to...

Sanitary Centrifugal Pump: 3 Basic Facts You Should Know Centrifugal pumps were the world’s 189th...

Pump Efficiency: 6 Common Questions Answered Pumps are a critical piece in industrial processes...

Introducing Q-Line Fittings Sanitary Fittings is pleased to announce their newest family of...

The Seven Types of Brewery Hose Materials Brewery hoses serve an incredible function throughout...

Tri-Clamp Fittings Frequently Asked Questions (FAQ) Tri-Clamp Fittings FAQ We get a lot of...

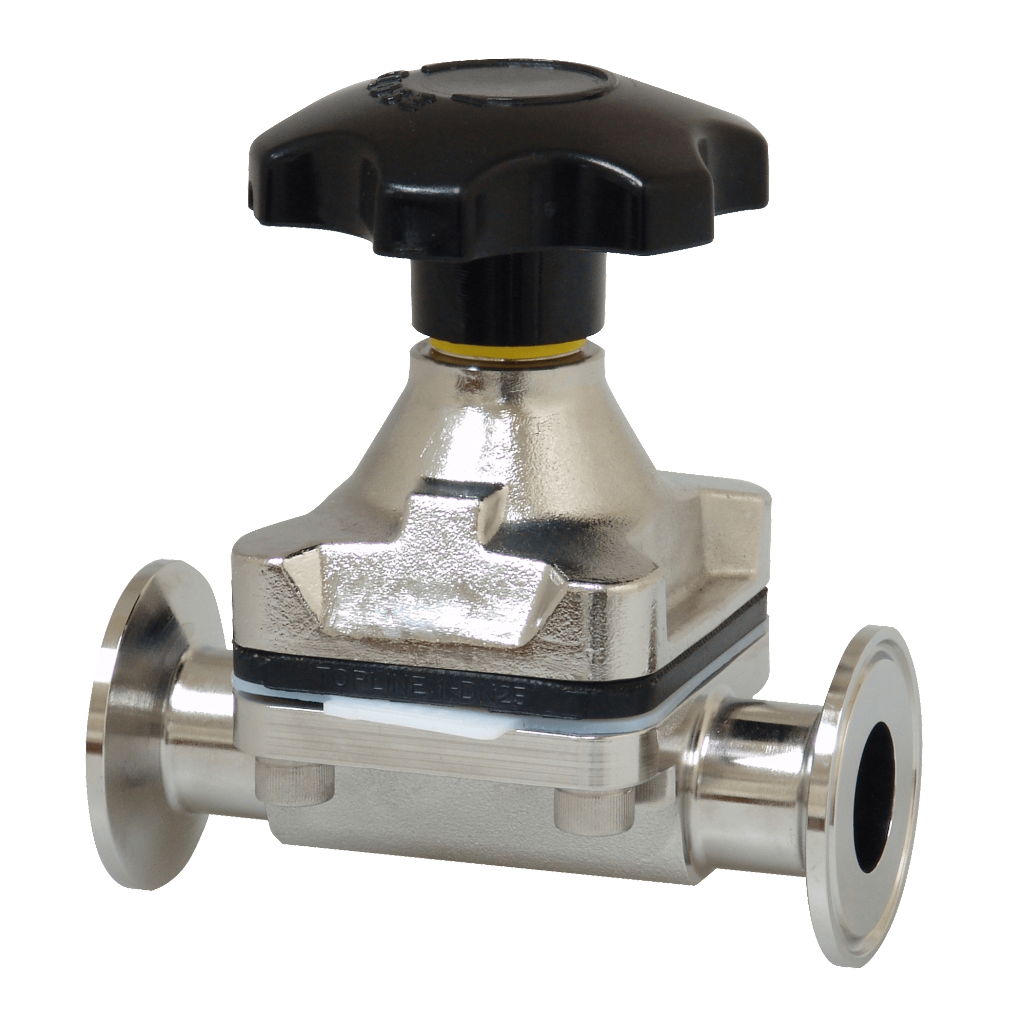

What is a Diaphragm Valve? Diaphragm valves use a flexible seal to control the flow of liquids or...

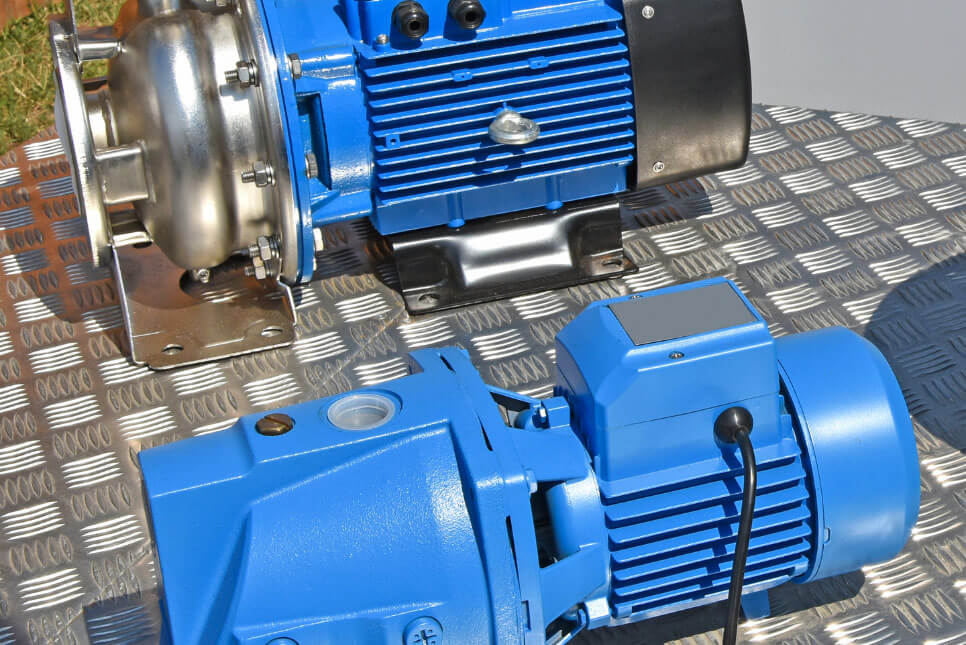

Sanitary Fittings is proud to start offering Sanitary Pumps as part of its product line. TOP-FLO®...

The Benefits of Tri-Clamp Butterfly Valves in Your Brewing System Brew day is over. Your ale,...

The Tri-Clamp Ball Valve: Every Brewer’s Superhero Homebrewing may seem like just another “silly...

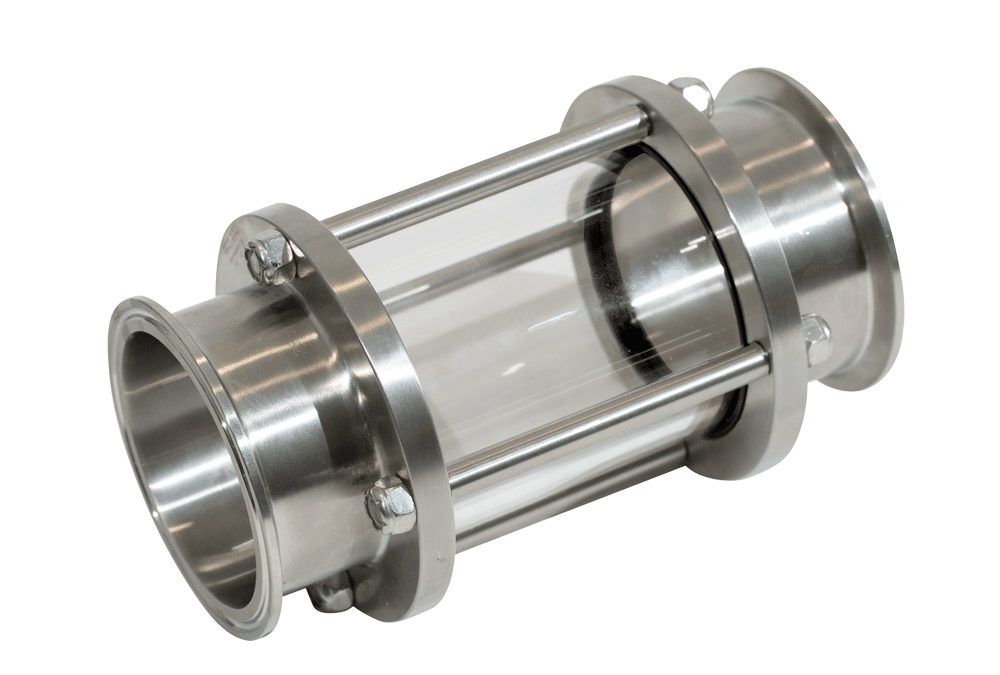

A Tri-clamp sight glass gives the brewer a sneak-peak into the wonderful pipeworks, boilers, and...

A Guide to Tri-Clamp Reducers/h1> When you buy that first home brewing kit, you get just about...

Once upon a time, a beginner home brewer set out to make a batch of rich, caramel-and-toffee...

A Guide to Tri-Clamp Spools Maybe you’re new to the homebrewing world and wonder where you can go...

Your Guide to Using a Camlock Fittings in Your Brewery...

Types of Gasket Tri-Clamp Fittings Used in Brewing Brewing is a fascinating process. Every element...

6 Essential Sanitary Fittings You Need to Know About We know a good beer when we taste it. Fizz...

A shortage of Sanitary Tubing?!? Say it ain’t so. “In this world, nothing is certain except death...

Can I Skimp on My Brewing Hoses? You live, breathe and dream beer. You’ve been an enthusiast of...