Tri-Clamp Butterfly Valves (BFVPC)

- Sanitary Clamp Butterfly Valve

- 316 Stainless Steel

- Operating Temperatures: 15° F – 200° F

- Information supplied based on water media at 68°F

- 32Ra Finish (Roughness Average)

- Field serviceable.

- Butterfly Valve Operating Manual

- View Sizes and Dimensions

Sanitary tri-clamp butterfly valve for easy process control

Clamp Butterfly Valve comes with a pull-trigger locking mechanism to control process flow. Tri-clamp connections allow for easy field disassembly for clean-in-place processes. This product comes standard in 316L stainless steel alloy.

We recommend clamp gaskets and our single-pin heavy duty clamp in order to safely connect this product to the rest of your system.

Butterfly Valve Operating Manual

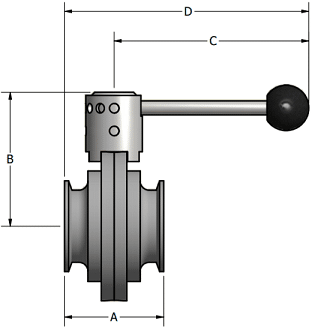

Tri-Clamp Butterfly Valve Part Numbers & Dimensions

| Size (Tube OD) |

Part Number | Dimensions | Break Torque | Pressure Rating | Flow Coefficient | |||

|---|---|---|---|---|---|---|---|---|

| EPDM | A | B | C | D | in/lbs | (PSI) | (CV) | |

| 1 " | BFVPC-1-316-EPDM | 2.60 | 3.20 | 5.49 | 6.79 | 75 | 140 | 23 |

| 1-1/2" | BFVPC-1.5-316-EPDM | 2.60 | 3.33 | 5.49 | 6.79 | 130 | 140 | 80 |

| 2 " | BFVPC-2-316-EPDM | 2.75 | 3.72 | 5.49 | 6.87 | 165 | 140 | 230 |

| 2-1/2" | BFVPC-2.5-316-EPDM | 2.75 | 3.85 | 5.49 | 6.87 | 210 | 110 | 264 |

| 3 " | BFVPC-3-316-EPDM | 3.00 | 4.25 | 5.49 | 7.00 | 350 | 110 | 372 |

| 4 " | BFVPC-4-316-EPDM | 3.00 | 4.75 | 6.87 | 8.37 | 540 | 85 | 800 |

How to Measure Tri-Clamp Fittings

Tri-Clamp Fittings and Gasket Sizing Guide

| Sanitary Size |

Flange OD (?) |

Tube ID (?) |

Tube OD (?) |

|---|---|---|---|

| 1/2″ | 0.984 | 0.370 | 0.500 |

| 3/4″ | 0.984 | 0.620 | 0.750 |

| 1″ | 1.984 | 0.870 | 1.000 |

| 1 1/2″ | 1.984 | 1.370 | 1.500 |

| 2″ | 2.516 | 1.870 | 2.000 |

| 2 1/2″ | 3.047 | 2.370 | 2.500 |

| 3″ | 3.579 | 2.870 | 3.000 |

| 4″ | 4.682 | 3.834 | 4.000 |

| 6″ | 6.562 | 5.782 | 6.000 |

| 8″ | 8.602 | 7.782 | 8.000 |

| 10″ | 10.570 | 9.782 | 10.000 |

| 12″ | 12.570 | 11.760 | 12.000 |

Looking for even more information on Tri-Clamp fittings?

We have everything you need. Read "The Ultimate Guide to Tri-Clamp Fittings"

Additional information

Line Drawings

| SKU | Description | Line Drawing |

|---|---|---|

| BFVPC-1-304-EPDM | 1″ Tri-Clamp Butterfly Valve, EPDM Seat, 304 |

|

| BFVPC-1-304-SILICONE-RED | 1″ Tri-Clamp Butterfly Valve, Silicone [Red] Seat, 304 |

|

| BFVPC-1-304-VITON | 1″ Tri-Clamp Butterfly Valve, Viton Seat, 304 |

|

| BFVPC-1-316-EPDM | 1″ Tri-Clamp Butterfly Valve, EPDM Seat, 316 |

|

| BFVPC-1-316-SILICONE-RED | 1″ Tri-Clamp Butterfly Valve, Silicone Seat, 316 |

|

| BFVPC-1-316-VITON | 1″ Tri-Clamp Butterfly Valve, Viton Seat, 316 |

|

| BFVPC-1.5-304-EPDM | 1-1/2″ Tri-Clamp Butterfly Valve, EPDM Seat, 304 |

|

| BFVPC-1.5-304-SILICONE-RED | 1 1/2″ Tri-Clamp Butterfly Valve, Silicone [Red] Seat, 304 |

|

| BFVPC-1.5-304-VITON | 1-1/2″ Tri-Clamp Butterfly Valve, Viton Seat, 304 |

|

| BFVPC-1.5-316-EPDM | 1-1/2″ Tri-Clamp Butterfly Valve, EPDM Seat, 316 |

|

| BFVPC-1.5-316-SILICONE-RED | 1-1/2″ Tri-Clamp Butterfly Valve, Silicone Seat, 316 |

|

| BFVPC-1.5-316-VITON | 1-1/2″ Tri-Clamp Butterfly Valve, Viton Seat, 316 |

|

| BFVPC-2-304-EPDM | 2″ Tri-Clamp Butterfly Valve, EPDM Seat, 304 |

|

| BFVPC-2-304-SILICONE-RED | 2″ Tri-Clamp Butterfly Valve, Silicone [Red] Seat, 304 |

|

| BFVPC-2-304-VITON | 2″ Tri-Clamp Butterfly Valve, Viton Seat, 304 |

|

| BFVPC-2-316-EPDM | 2″ Tri-Clamp Butterfly Valve, EPDM Seat, 316 |

|

| BFVPC-2-316-SILICONE-RED | 2″ Tri-Clamp Butterfly Valve, Silicone Seat, 316 |

|

| BFVPC-2-316-VITON | 2″ Tri-Clamp Butterfly Valve, Viton Seat, 316 |

|

| BFVPC-2.5-304-EPDM | 2 1/2″ Tri-Clamp Butterfly Valve, EPDM Seat, 304 |

|

| BFVPC-2.5-304-SILICONE-RED | 2 1/2″ Tri-Clamp Butterfly Valve, Silicone [Red] Seat, 304 |

|

| BFVPC-2.5-304-VITON | 2 1/2″ Tri-Clamp Butterfly Valve, Viton Seat, 304 |

|

| BFVPC-2.5-316-EPDM | 2-1/2″ Tri-Clamp Butterfly Valve, EPDM Seat, 316 |

|

| BFVPC-2.5-316-SILICONE-RED | 2-1/2″ Tri-Clamp Butterfly Valve, Silicone Seat, 316 |

|

| BFVPC-2.5-316-VITON | 2-1/2″ Tri-Clamp Butterfly Valve, Viton Seat, 316 |

|

| BFVPC-3-304-EPDM | 3″ Tri-Clamp Butterfly Valve, EPDM Seat, 304 |

|

| BFVPC-3-304-SILICONE-RED | 3″ Tri-Clamp Butterfly Valve, Silicone [Red] Seat, 304 |

|

| BFVPC-3-304-VITON | 3″ Tri-Clamp Butterfly Valve, Viton Seat, 304 |

|

| BFVPC-3-316-EPDM | 3″ Tri-Clamp Butterfly Valve, EPDM Seat, 316 |

|

| BFVPC-3-316-SILICONE-RED | 3″ Tri-Clamp Butterfly Valve, Silicone Seat, 316 |

|

| BFVPC-3-316-VITON | 3″ Tri-Clamp Butterfly Valve, Viton Seat, 304 |

|

| BFVPC-4-304-EPDM | 4″ Tri-Clamp Butterfly Valve, EPDM Seat, 304 |

|

| BFVPC-4-304-SILICONE-RED | 4″ Tri-Clamp Butterfly Valve, Silicone [Red] Seat, 304 |

|

| BFVPC-4-304-VITON | 4″ Tri-Clamp Butterfly Valve, Viton Seat, 304 |

|

| BFVPC-4-316-EPDM | 4″ Tri-Clamp Butterfly Valve, EPDM Seat, 316 |

|

| BFVPC-4-316-SILICONE-RED | 4″ Tri-Clamp Butterfly Valve, Silicone Seat, 316 |

|

| BFVPC-4-316-VITON | 4″ Tri-Clamp Butterfly Valve, Viton Seat, 316 |

|

| BFVPC-6-316-SILICONE-RED | 6″ Tri-Clamp Butterfly Valve, Silicon Red Seat, 316L |

|

| BFVPC-6-316-VITON | 6″ Tri-Clamp Butterfly Valve, Viton Seat, 316L |

-

I am looking to purchase either of our style BF valve and wanted to know the low end temp. Processing a brine of calcium chloride and needs it to go to -50 F. Can your butterfly valve handle this range?

-

Q I am looking to purchase either of our style BF valve and wanted to know the low end temp. Proces...... Read moreA That's a difficult application. The temperature dictates the use of silicone seals in the BFV, however due to shrinkage of the stainless and silicone seal itself we can't guarantee the function because there's been no testing at that temperature performed. I'm thinking at that temperature our customer's customer is doing cannabis extraction of some kind. Usually the method of extraction is with ethanol.

Are the 1in,1.5 in butter fly valve seats rebuildiable?

-

Q Are the 1in,1.5 in butter fly valve seats rebuildiable?A We do offer valve-seat repair kits. However, these repair kits are specific to the manufacturer of the valve. If the valve you are trying to repair is from another source there is about an 80% chance that our seal kits will not be compatible.

Can we sterilize the 4" butterfly valve by Steam-in-place sterilization at 121oC/15 psi without any leaks?

-

Q Can we sterilize the 4" butterfly valve by Steam-in-place sterilization at 121oC/15 psi without a...... Read moreA We do not suggest steam cleaning for our butterfly valves. If you must use this process we recommend our ball valves instead.

When partially open, does the valve have 'stops' or lock-locations, or is it infinitely adjustable between open and close?

-

Q When partially open, does the valve have 'stops' or lock-locations, or is it infinitely adjustabl...... Read moreA The tri-clamp butterfly valve with a pull handle has four (4) locking locations. Alternatively, our Trigger Handle Butterfly Valve has twelve (12) locking locations.

Is this valve NSF61 certified for water?

-

Q Is this valve NSF61 certified for water?A This is not a sanitary document we can provide for any of our valves.

What is the max pressure for a 1”?

-

Q What is the max pressure for a 1”?A The pressure rating on the 1" Tri-Clamp Butterfly Valve is 140PSI.

What is the max pressure for a 1”?

-

Q What is the max pressure for a 1”?A

This valve has been tested to a pressure of 140PSI for the 1" version.

Will this valve leak if one side is placed under vacuum and the other side is exposed to air?

-

Q Will this valve leak if one side is placed under vacuum and the other side is exposed to air?A These valves are designed to withstand a certain amount of pressure both internal and external. At some point, the valve will fail under pressure but it all depends on the strength of the vacuum you are applying.

What is the seat material of these valves? Also, do you know the recommended temperature range?

-

Q What is the seat material of these valves? Also, do you know the recommended temperature range?A The seat material for our tri-clamp butterfly valves is EPDM. We also can offer this in Viton. Regarding the temperature range, EPDM is rated to temperatures of +250°F.