TOP-FLO® BIOPRO® Forged Diaphragm Valve (74L3)

- Sanitary Tri-Clamp Diaphragm Valve

- Manufactured from ASTM A182 GR F316L

- 20RA ID (SF1)

- Meets Bioprocessing Equipment (BPE) Standards

- BPE 2019 0.005-0.017 with 3.1 Material Certification

- Autoclavable FKM O-ring sealed 304SS stainless steel manual bonnet

- PPS Thermoplastic Handwheel

- This Product Normally Ships in 1 – 2 Days

- Replacement Bayonets Available

- View Sizes and Dimensions

Sanitary tri-clamp diaphragm valve plug valves for high-purity process piping applications

BIOPRO® forged bodies are manufactured from ASTM A182 GR F316L material with additional controls in regards to chemical content. The sulfur content is maintained to meet and exceed the stringent requirements of BPE. All forgings are solution annealed to maintain the ferrite content to be .05% or less. This low ferrite content eliminates the concern for contaminants and migration of oxides throughout the system. Machining of the contours is performed by using state of the art cad/cam system assuring repeatability of the weir and valve cavity profiles for full drainability. Each forging contains two hash marks clearly indicating the drain angle plane for ease of installation.

BIOPRO® forged bodies are in compliance with FDA guidelines as well as cGMP principles and are specifically designed for use in ultra-pure applications where sterility is critical. Steel & O’Brien provides these bodies with heat numbers etched into them for full traceability. Mill test summaries are provided with each shipment. BIOPRO® forged diaphragm valves are available in sizes ranging from 1/2” through 6” with clamp or weld end connections and surface finishes ranging through 10 RA. Learn more about Diaphragm Valves.

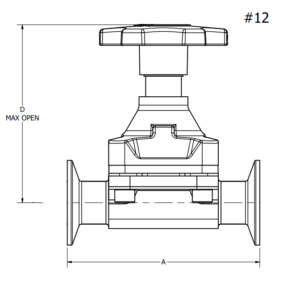

Diaphragm Valve Part Numbers & Dimensions

| Part Number | Sanitary Size | Material | A Clamp End | D Center To Top | Drain Angle |

|---|---|---|---|---|---|

| 74L3-12-1K-50-20RA-316L | 1/2" | Teflon | 3.50" | 3.27" | 30° |

| 74L3-12-2E-50-20RA-316L | 1/2" | EPDM | 3.50" | 3.27" | 30° |

| 74L3-12-1K-75-20RA-316L | 3/4" | Teflon | 4.00" | 3.66" | 25° |

| 74L3-12-2E-75-20RA-316L | 3/4" | EPDM | 4.00" | 3.66" | 25° |

| 74L3-12-1K-10-20RA-316L | 1" | Teflon | 4.50" | 4.17" | 28° |

| 74L3-12-2E-10-20RA-316L | 1" | EPDM | 4.50" | 4.17" | 28° |

| 74L3-12-1K-15-20RA-316L | 1-1/2" | Teflon | 5.50" | 6.10" | 20° |

| 74L3-12-2E-15-20RA-316L | 1-1/2" | EPDM | 5.50" | 6.10" | 20° |

| 74L3-12-1K-20-20RA-316L | 2" | Teflon | 6.25" | 7.07" | 20° |

| 74L3-12-2E-20-20RA-316L | 2" | EPDM | 6.25" | 7.07" | 20° |

How Does a Diaphragm Valve Work?

The diaphragm valve opens and closes via a turn handle which is connected to a plunger. The plunger applies pressure to the diaphragm which then flexes up or down to control flow. Turning the handle clockwise will lower the diaphragm causing flow to decrease while turning the handle counterclockwise raises the diaphragm increasing product flow through the valve.

Additional information

-

Can manually operated 3" O.D. Diaphragm Valves be installed in the vertical? does it affect operation/sealing?

-

Q Can manually operated 3" O.D. Diaphragm Valves be installed in the vertical? does it affect opera...... Read moreA Diaphragm valves can be installed either horizontally or vertically without affecting operation or sealing.