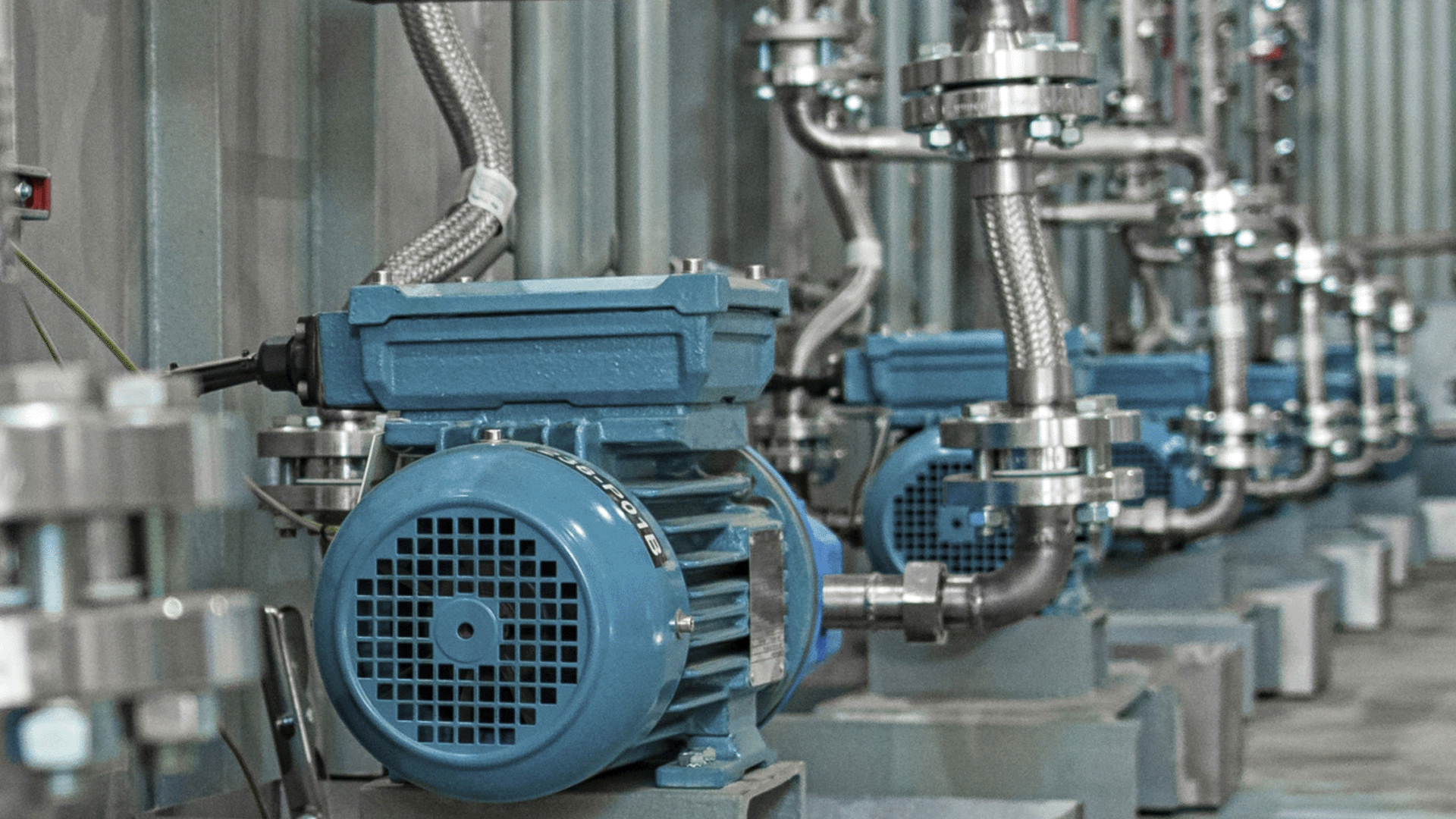

For applications that require sanitary centrifugal pumps, ensuring consistent performance and reliability is essential. One of the key metrics for evaluating pump performance is the Mean Time Between Failures (MTBF). A high MTBF indicates that a pump is operating efficiently... keep reading

Sanitary Centrifugal Pumps

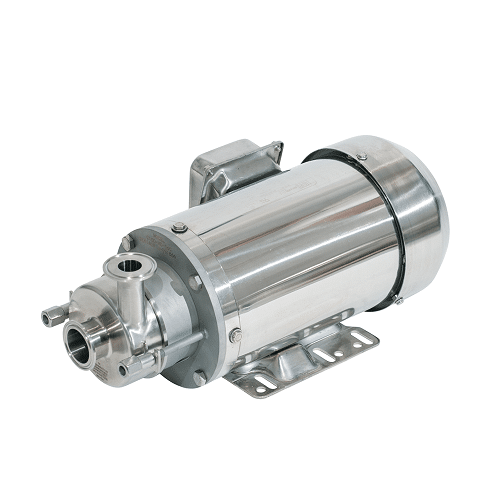

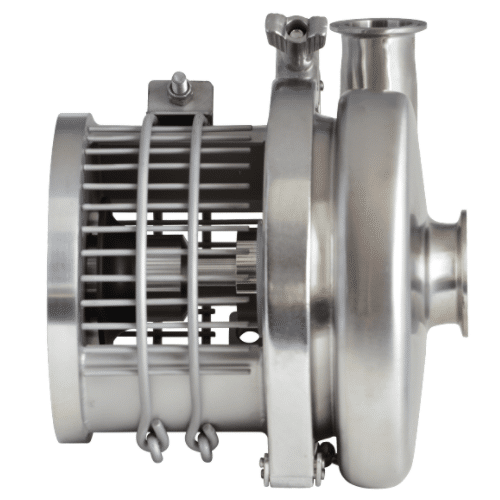

The centrifugal pump is ideal for use in small and medium-size process applications in the dairy, food, beverage, pharmaceutical, and other sanitary process industries. TOP-FLO® pumps are suitable for use in CIP (clean-in-place) installations. This feature enables easy self-cleaning with no dismantling or take-down. Sanitizing all product contact areas is automatic. Learn how to calculate pump flow rate.

Most Pumps and Accessories ship within 1 day with the TOP-FLO® Ready-To-Go program

See our Ultimate Guide to Sanitary Pumps to learn more.

Products

Showing 1–12 of 19 resultsSorted by popularity

-

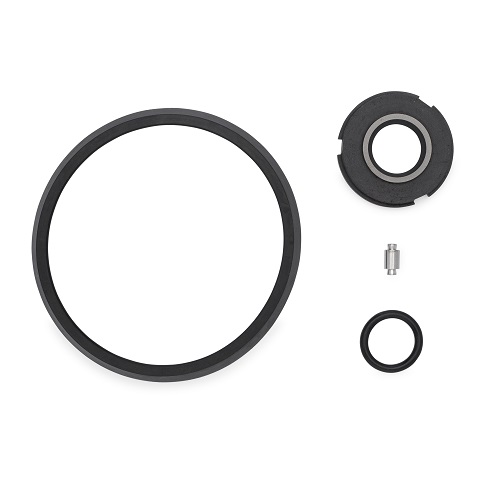

Centrifugal Pump Seal Repair Kit 3

-

TF-C100 Centrifugal Pump

-

TF-C114 Centrifugal Pump

-

TF-C216 Centrifugal Pump

-

TF-C218 Centrifugal Pump

-

TF-C328 Centrifugal Pump

-

Centrifugal Pump Seal Repair Kit 1

-

Drive Collar (MAR00)

-

83C Stuffing Box

-

Follower

-

Castellated Nut (Acme Thread)

-

Centrifugal Pump Stub Shaft (MAR006)

Related Blog Posts

6 Sanitary Pump Technical Terms and Their Meanings

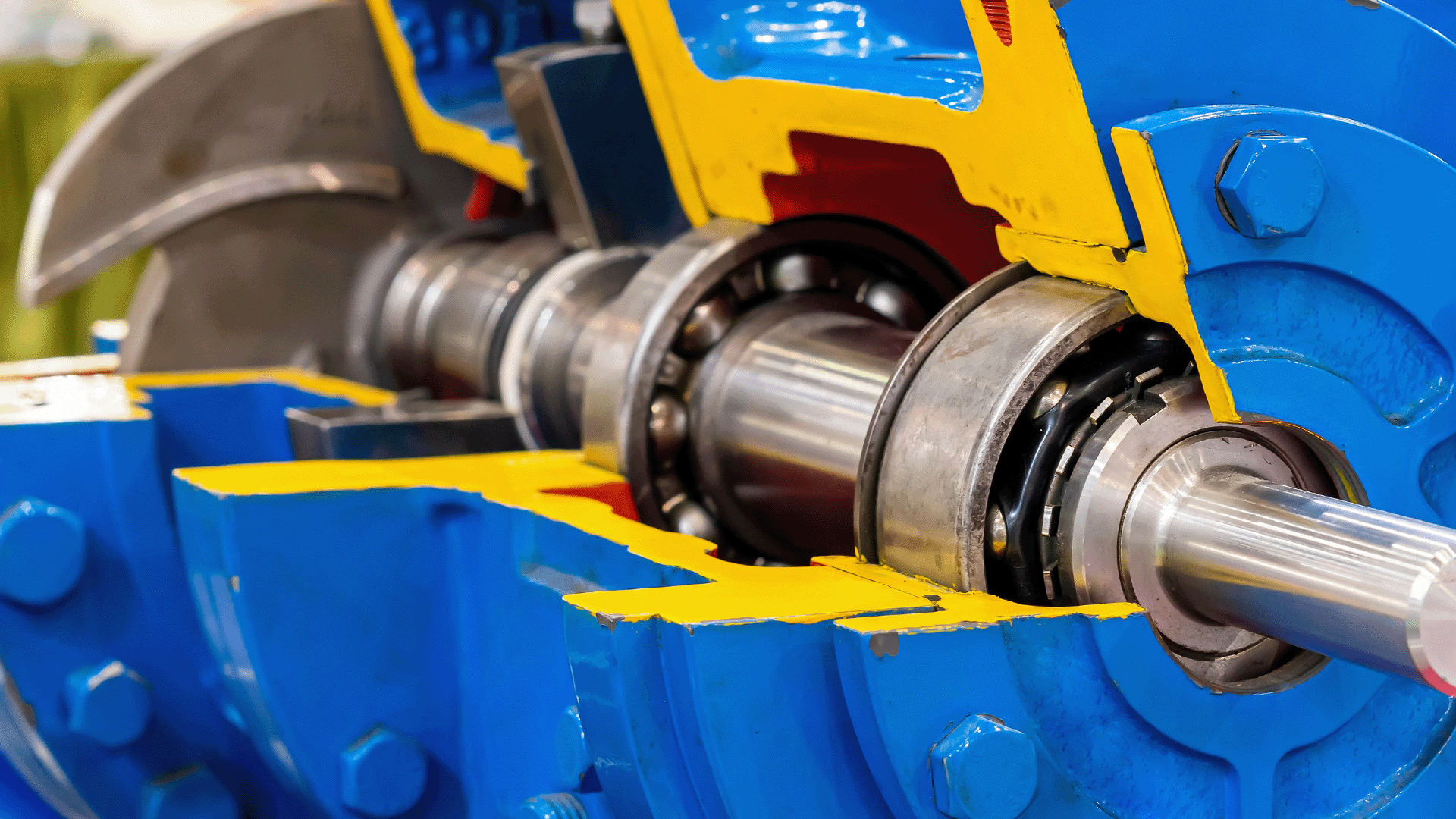

Centrifugal pumps are one of the most commonly used pieces of equipment and have an ever-expanding field of application. Like all equipment, these pumps also need their fair share of care and maintenance to keep them running in tip-top shape.... keep reading

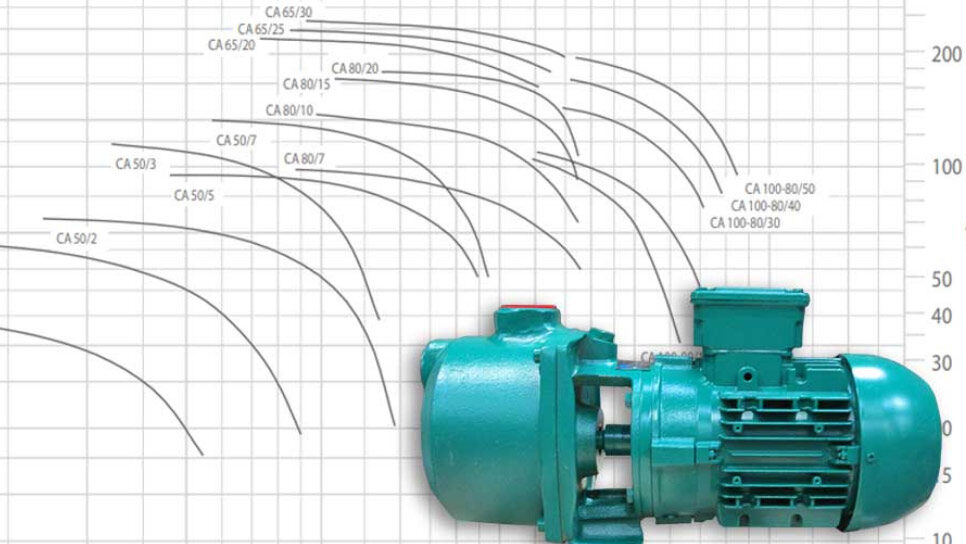

Pump Curve: Expert Tips on How to Read and Use It

A pump curve is a graphical representation of how a sanitary pump will operate under different conditions. It provides pump operators with important information, such as head pressure and flow rate, to help them determine the right pump for a... keep reading