Drive Collar (MAR00)

- “D” / “E” Series Centrifugal Pump Drive Collar

- Available in sizes: 114, 216, 328

- Centrifugal Pump Manual

Replacement Centrifugal Pump Drive Collar

From time to time, centrifugal pump mechanical components need to be replaced. TOP-FLO® centrifugal pump replacement parts are specifically designed to fit in the pumps of not only TOP-FLO® pumps but those of major pump suppliers. These components are rugged and will provide the necessary sealing conditions under a wide range of conditions.

Drive Collar Adjustment

(Models TF-C114 through TF-C328)

- Slide the seal drive collar onto the stub

shaft as shown in Figure 24.

Use the “A” dimension in the SEAL CHART

to properly locate the drive collar on the

stub shaft. Tighten the set screws to

secure in place.

NOTE: TF-C100 pump does not require drive

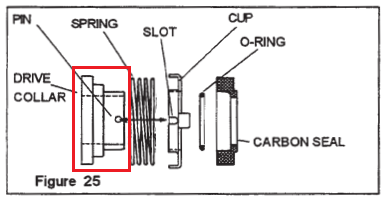

collar. - Assemble the spring, seal cup, o-ring, and

carbon seal, and install as a unit. Make

sure the slot in the seal cup aligns with

the pin on the shaft. (Figure 25) Gentle

pressure on the o-ring will overcome

resistance on the shaft.

NOTE: Do not lubricate seals with any

type of oil or grease, the seal faces will be

lubricated by the product being pumped. - Assemble the gasket to the backplate.

Install the backplate on the adapter. Make

sure the seal cup slot is engaged with the

pin on the drive collar. (Figure 25) - Rotate the backplate until the backplate

pins engage the adapter pins. (Figure 25) - Rotate the shaft until the pin hole in the

end is in a horizontal position. Insert the

impeller pin, center it in the shaft end, and

slide the impeller on the shaft.

Hold the impeller tight against the stub

shaft and rotate the shaft one-fourth turn

until the impeller pin drops and secures the

impeller. (Figure 26) - Place the casing over the impeller/

backplate, close and tighten the clamp.

(Figure 27) - Assemble the cascade water fitting, if

included. Install the seal guard and tighten

in place. Assemble the suction line and the

discharge line to the casing.

NOTE: Check for strain or misalignment

of piping to the casing. Re-adjust the

casing ports and/or entire motor leveling as

necessary.

Additional information

Line Drawings

| SKU | Description | Line Drawing |

|---|---|---|

| MAR00701S-316 | #80J 114E-23-316 E SEAL | Request Line Drawing |

| MAR00731S-304 | #80L SP114D-23P-316 DG SEAL | |

| MAR00736S-304 | #80L SP216D-23P-316 MILL | Request Line Drawing |

| MAR00711-316 | #80J 216E-23-316 MILL | Request Line Drawing |

| MAR00741S-304 | #80L SP328D-23P-316 MILL | Request Line Drawing |

| MAR00721 | #80J 328E-23-316 MILL | Request Line Drawing |

There are no questions yet. Be the first to ask a question about this product.