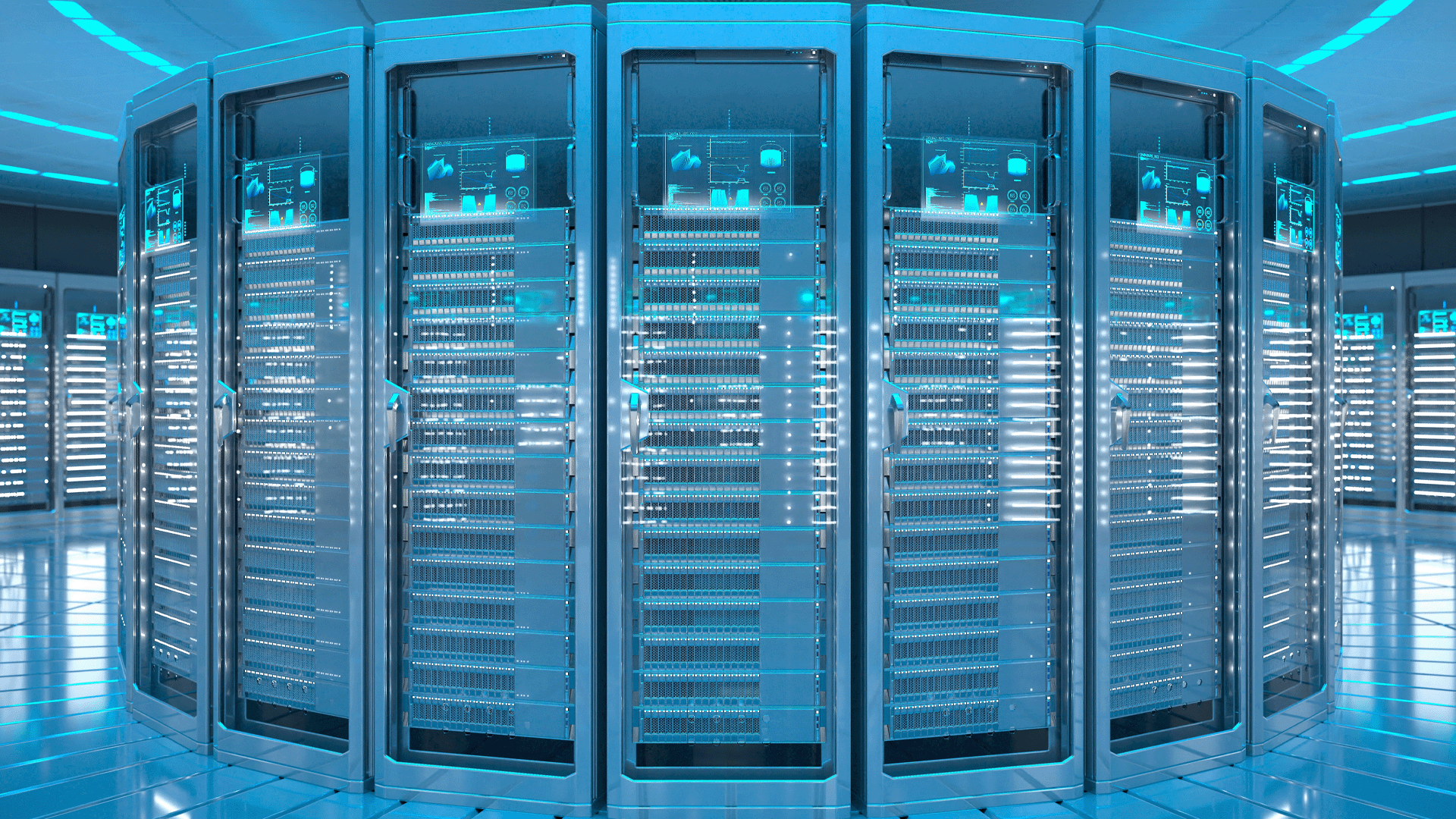

Data centers are the heart of many of today’s business operations. They power everything from streaming platforms and cloud storage to financial systems and AI models. Behind every server rack there is one critical challenge: heat. Managing that heat efficiently... keep reading

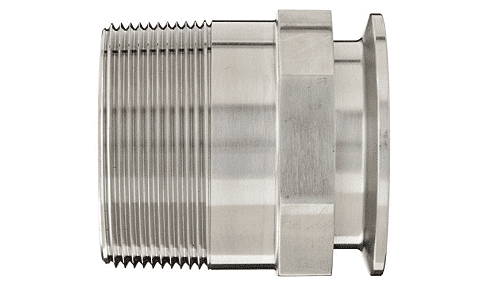

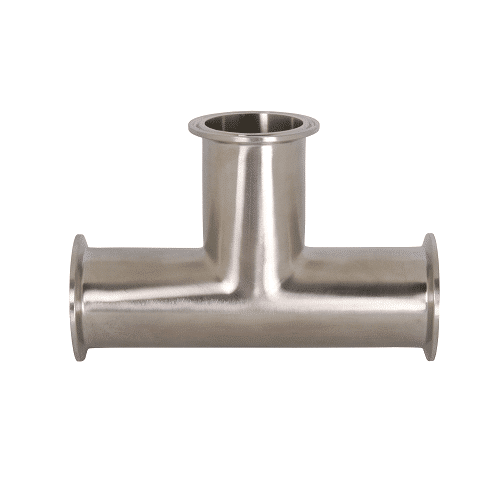

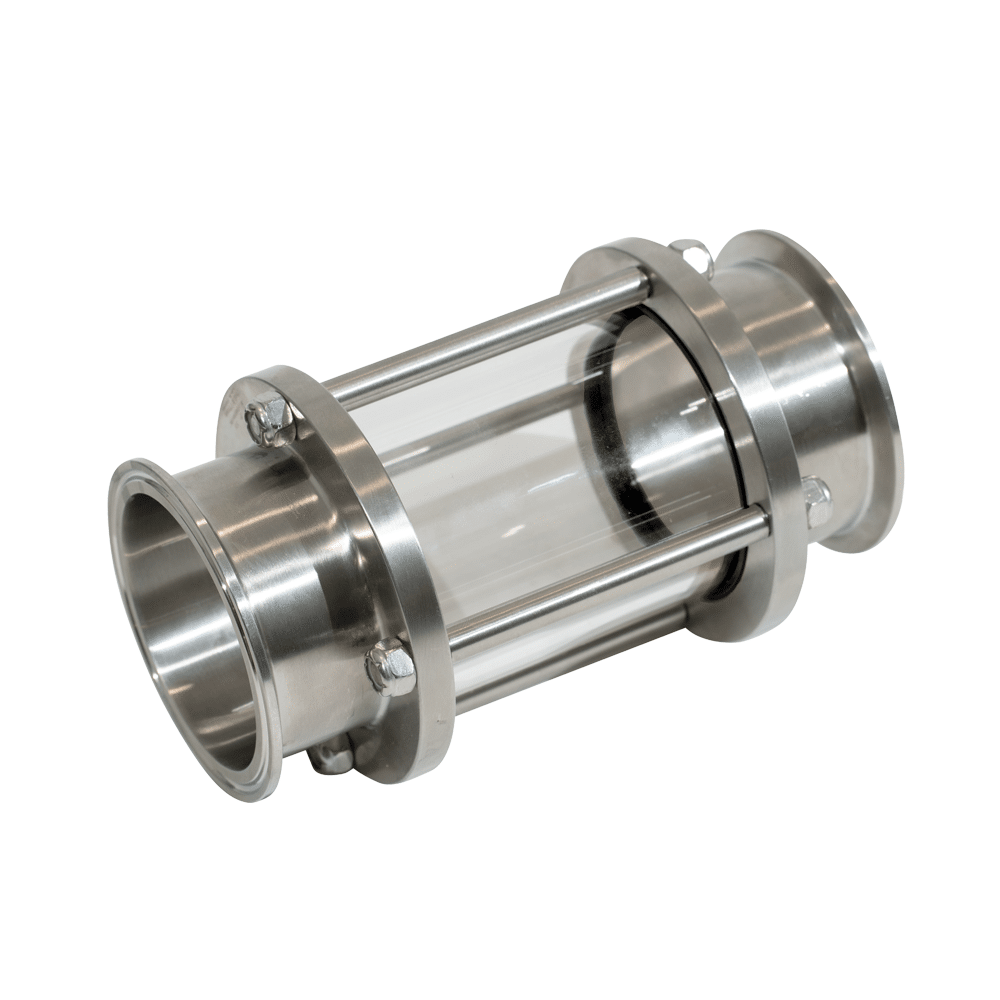

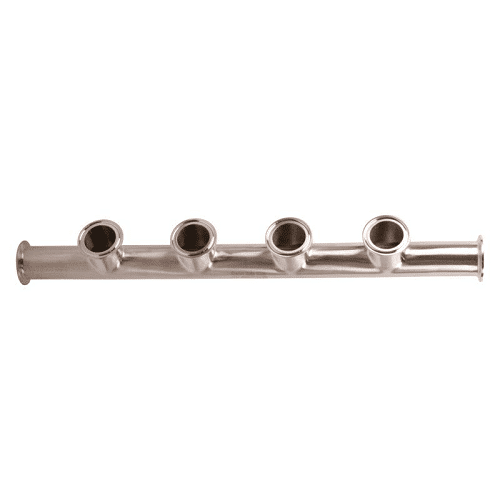

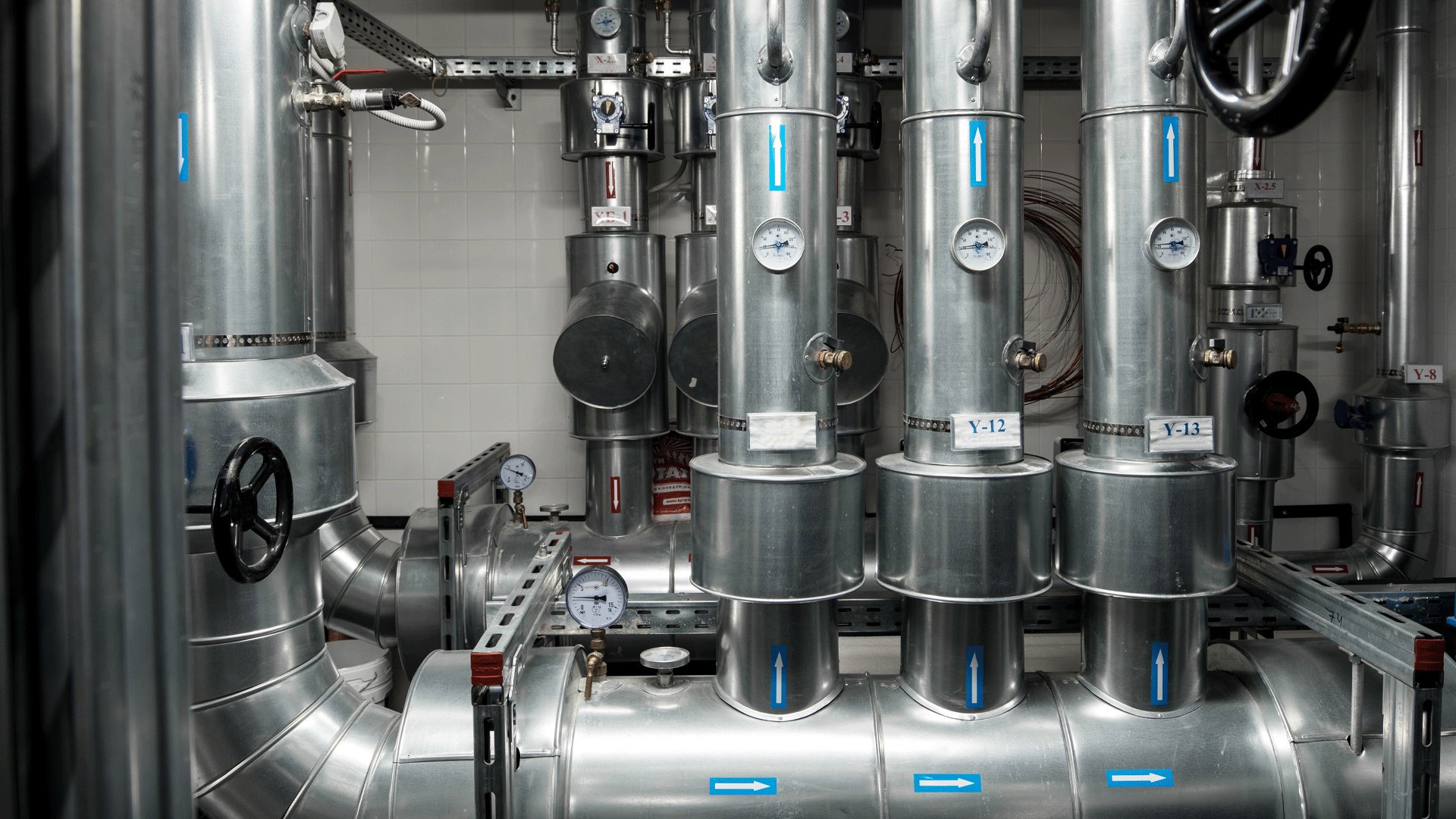

Tri-Clamp Fittings

Stainless steel tri-clamp fittings are the most popular style of process line equipment used within the food, beverage, and pharmaceutical industries. These fittings quickly create a leak-proof connection to allow for easy assembly, routine maintenance and inspection.

Tri-Clamp connections require a gasket and clamp to complete a leak-proof seal. To learn more please see our Frequently Asked Questions or read our Ultimate Guide to Tri-Clamp Fittings

Available in both 304 and 316L stainless steel alloys (what’s the difference) and manufactured in accordance with 3A Standards. Material Test Reports (MTRs) available upon request. Sanitary Fittings has access to a large amount of inventory so most orders include same day shipping.

Products

Showing 1–12 of 61 resultsSorted by popularity

-

Tri-Clamp Brewery Hose Adapters (14MPHRL)

-

Tri-Clamp Long-Weld Ferrule (14AM7)

-

Tri-Clamp Short Ferrule (14WMP)

-

Single-Pin Heavy Duty Clamp (13MHHM)

-

Light Duty Tank Ferrules (14WLMP)

-

Heavy Wall Tank Weld Ferrule (14MPW)

-

Roll-On Expanding Ferrules (14RMP)

-

Tri-Clamp Hose Adapters (14MPHR)

-

Tri-Clamp Thermometer Cap (23BMP)

-

High Pressure Tri-Clamp (13MHP)

-

Tri-Clamp End Caps (16AMP)

-

90° Tri-Clamp Elbow (2CMP)

Related Blog Posts

Understanding Liquid Cooling Methods in Modern Data Centers

As data centers grow more powerful, the challenge of keeping servers cool becomes more complex. Traditional air cooling methods, once sufficient for lower-density racks, are now struggling to keep pace with today’s heavy workloads. Liquid cooling has emerged as the... keep reading

Why Stainless Steel Components Are Essential for Liquid-Cooled Data Centers

As data centers grow in size, density, and power demand, liquid cooling has rapidly become the preferred solution for managing heat efficiently. But choosing the right materials for those cooling systems is just as important as the cooling technology itself.... keep reading