Sanitary tubing and fittings are easy to treat as “just piping.” They are often specified early, installed quickly, and then forgotten until...

Expert insights on all things sanitary

Sanitary Fittings Blog

Explore in-depth guides, industry trends, and best practices for the food, beverage, pharmaceutical, and manufacturing industries. For all professionals committed to safety, compliance, and performance.

Quick Menu

All Blog Categories

Popular Categories

Latest Blog Posts

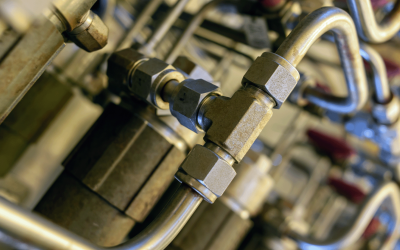

Why Sanitary Tubing and Fittings Matter More Than You Think

What Are Sanitary Hoses? Uses, Materials, and Selection Basics

How to Choose the Right Sanitary Hose for Your Facility (Selection Checklist)

All Blog Posts

What Are Sanitary Hoses? Uses, Materials, and Selection Basics

Sanitary hoses are flexible transfer lines designed for hygienic processing environments. You will see them anywhere product, cleaning...

How to Choose the Right Sanitary Hose for Your Facility (Selection Checklist)

Sanitary hoses are one of those components that can quietly make or break a process. The right hose transfers product efficiently and stands up...

How to Choose the Right Sanitary Valve for Your Process

Choosing a sanitary valve is rarely about picking a “good” valve. It’s about choosing the right valve for how your line actually runs: what...

Data Center Cooling: How It Works and Sanitary Components That Improve Reliability

Data centers are the heart of many of today's business operations. They power everything from streaming platforms and cloud storage to...

Understanding Liquid Cooling Methods in Modern Data Centers

As data centers grow more powerful, the challenge of keeping servers cool becomes more complex. Traditional air cooling methods, once...

Why Stainless Steel Components Are Essential for Liquid-Cooled Data Centers

As data centers grow in size, density, and power demand, liquid cooling has rapidly become the preferred solution for managing heat...

Sanitary Sample Valves: How to Select the Right Valve

Sanitary Sample Valves: What They Are, How They Work, and When to Use Them In hygienic processing, representative samples are essential for...

Best Practices for Cleaning and Maintaining Sanitary Sample Valves

Product quality and safety hinge on maintaining your sanitary equipment. Sanitary sample valves that are widely used in the food, beverage, and...

Best Practices for Cleaning and Maintaining Your Washdown Station Hose

Best Practices for Cleaning and Maintaining Your Washdown Station Hose In any sanitary processing facility, washdown stations and hoses are...

The Top 5 Features to Look for in High-Quality Washdown Hoses

Top 5 Features to Look for in High-Quality Washdown Hoses In any sanitary processing facility, maintaining cleanliness is not optional; it’s...

Understanding NPT Pipe Fittings: When and Where to Use Them

Choosing the right type of fitting is important for system integrity, safety, and compliance. One widely used fitting style is the NPT fitting....