Butterfly valves are a cornerstone of many sanitary valve applications in food and beverage production, breweries, and pharmaceutical production. Their compact design, ease of operation, and reliable flow control make them a favorite choice among engineers and procurement professionals looking to optimize process efficiency. Because there are multiple butterfly valve styles available, it can be challenging to decide which one best suits a specific application. In this post, we will discuss the key differences between lug style and wafer style butterfly valves and help you determine the most appropriate solution for your facility.

An Overview of Butterfly Valves

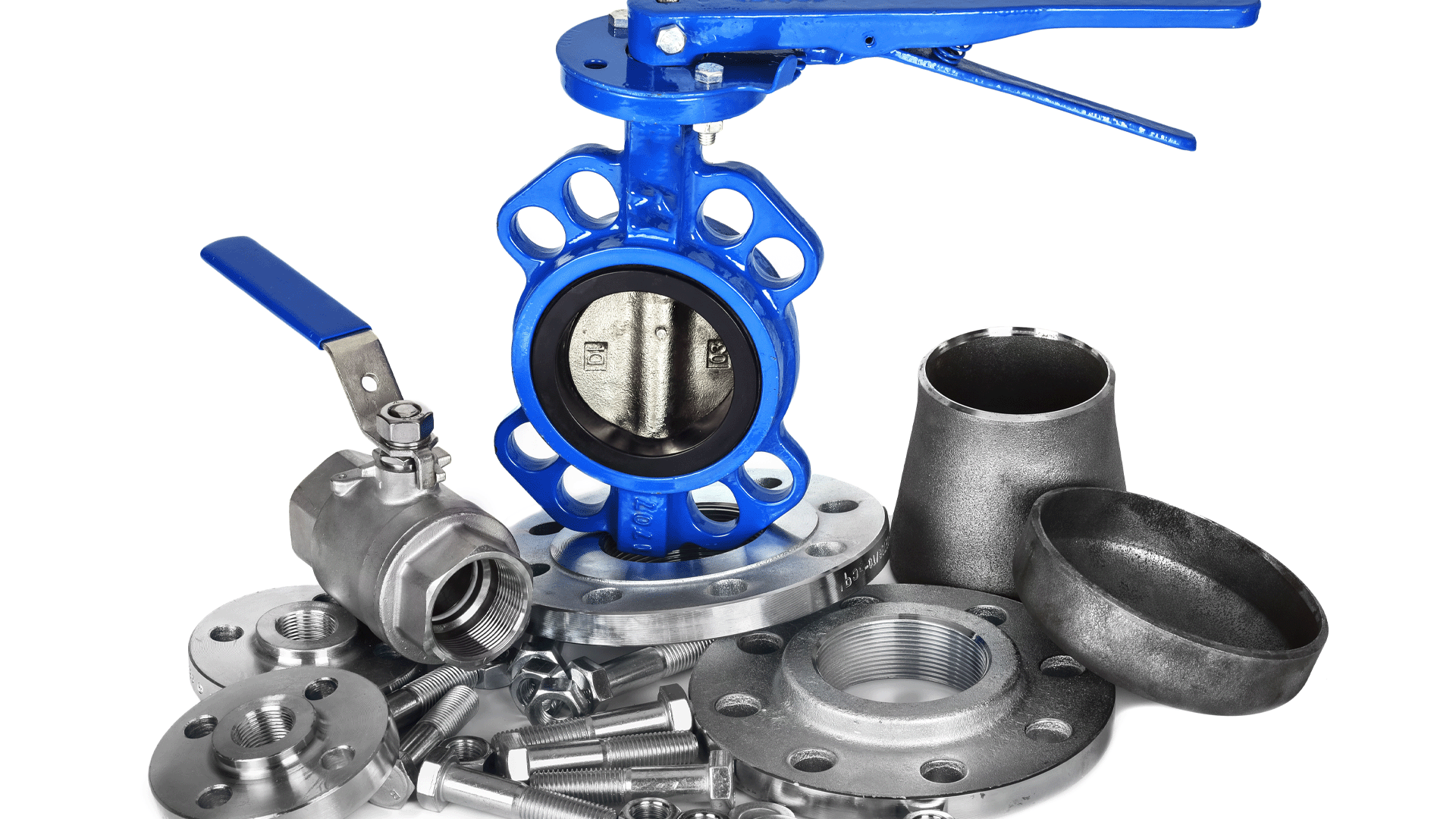

A butterfly valve utilizes a rotating disk (the “butterfly”) to control the flow of liquids or gases through a pipeline. In sanitary applications—where cleanliness, minimal contamination risk, and compliance with strict hygiene standards are paramount—tri-clamp butterfly valves are commonly used. These valves are also often automated, leading to automated butterfly valves that streamline process control and reduce manual handling.

Lug Style Butterfly Valves

Lug style butterfly valves are characterized by threaded inserts, often referred to as “lugs”, on the valve body. This design allows the valve to be securely bolted to the flanged valve connections on each side. One of the key advantages of a lug style valve is the ability to disconnect one side of the piping system at a time for maintenance or inspection without disrupting the entire line. This feature is particularly valuable in applications where partial system shutdowns are required for cleaning, repair, or routine checks.

- Easy maintenance: You can remove one side of the piping without disturbing the other side.

- Secure installation: Threaded inserts provide a robust and reliable connection.

- Versatility: Common in lines that may need isolation of specific sections.

For many in the food, beverage, and pharmaceutical industries, a lug style design can be an ideal choice if system downtime needs to be minimized while still maintaining sanitary conditions.

Wafer Style Butterfly Valves

Wafer style butterfly valves are installed by positioning the valve between two flanges. Long bolts, or studs, pass through both flanges and around the valve body to hold everything in place. This “sandwich” design is often more cost-effective and compact compared to the lug style.

- Cost efficiency: Typically less expensive due to simpler construction.

- Space-saving: Compact design suits tight piping configurations.

- Easy installation: Quick to install between flanges in a properly aligned system.

Wafer valves are a popular choice for many food processing and beverage operations, particularly where a straightforward, reliable, and cost-effective solution is necessary, and where the ability to isolate each side of the pipeline isn’t a primary requirement.

Choosing the Right Valve for Your Process

Deciding between a lug valve and a wafer valve often comes down to your specific maintenance needs, budget, and space constraints. If your line configuration demands frequent or selective shutdowns for Clean-In-Place (CIP) processes, a lug style butterfly valve’s independent line isolation might be essential. On the other hand, if you prioritize cost and simplicity—especially when you do not need to separately shut off portions of your line—wafer style butterfly valves can offer an excellent, sanitary solution.

When selecting a valve for brewery, food, beverage, or pharmaceutical applications, it’s crucial to consider system pressure, cleaning protocols, and any specialized industry standards. Should you require additional functionality, automated butterfly valves are widely available in both lug and wafer designs, giving you even more control and customization over your processes.

Ready to find the right butterfly valve for your application? Visit our Butterfly Valves page to explore our comprehensive selection of flanged, tri-clamp, lug, and wafer options. We’re here to help you choose the most effective solution for your process—feel free to reach out for assistance or guidance as you make this important decision.