Custom Manufacturing from Sanitary Fittings

While the majority of products that we sell are considered “off the shelf”, we also work with our customers to develop custom fabricated parts to fit their needs.

What is the Custom Manufacturing Process?

Our process usually starts out with a request from the customer. While we prefer to have detailed drawings from the customer this isn’t always the case. Sometimes we get rough dimensions and explanations, sometimes we get cocktail napkin sketches, and sometimes we receive just a rough idea of what the customer is trying to accomplish. Either way, we have a team of engineers and designers available to walk the customer through this process of clearly defining their needs.

Once we have defined all requirements for custom manufacturing we will provide an estimate to the customer. This can be a “one and done” email or may take several phone calls back and forth with the team to get all necessary information. With a quote provided the ball is now in the customer’s court to make a decision on whether or not to proceed with the order.

If the customer decides to move forward it is at this point that our team of engineers will provide a detailed drawing of the items to be manufactured. We then send these drawings back to the customer for final approval. If everything looks good we can move the order into our production queue. If changes are necessary the process repeats until the customer signs off on the custom items.

How Long Does This Process Take?

Our typical lead time for manufacturing custom products is about 5 – 10 days. This can vary due to several factors:

- How many other custom jobs are ahead of your work order in the production queue

- How complicated you custom order may be

- How large your custom order is

Once we have an approved drawing from the customer we can then get your order into our production queue and provide an accurate shipping date for your order.

What if Something is Wrong with My Order?

We have a team of Quality Assurance individuals whose job it is to throughly inspect all items before shipment. Our engineers and fabricators design and create items per the request and signed off form from the customers.

Having said that, yes, sometimes things don’t always go as planned. It’s possible for items to be damaged during shipment or that we did not manufacture to spec, however unlikely. If, for whatever reason you are not satisifed with your custom order please do not hesitated to contact us immediately so we can make things right.

Samples of Past Work

When we receive a request for a custom product I always like to walk the customer through our process so they know what to expect from us in terms of service deliverability. The most important thing to be considered with any custom product is just that, this is a custom product. As a customer, you have specific requirements for your products including dimensions, connection types, and materials used. As a supplier of these products, we want to make sure that we get this right the first time.

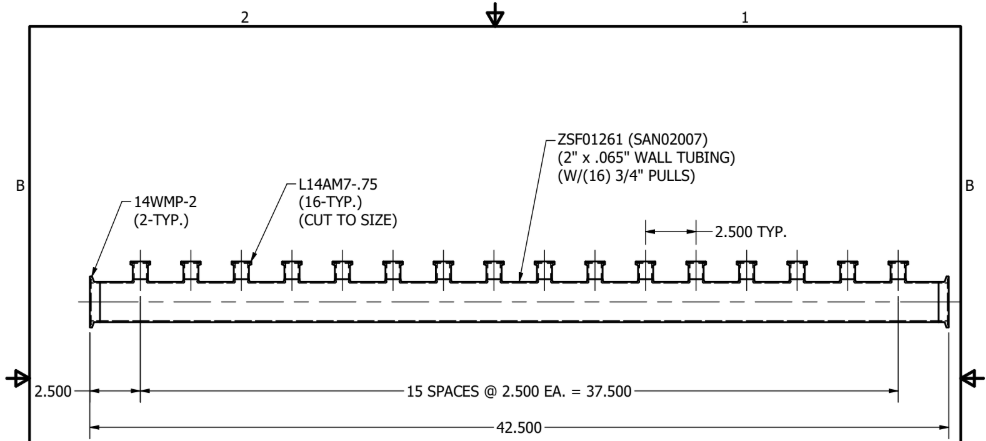

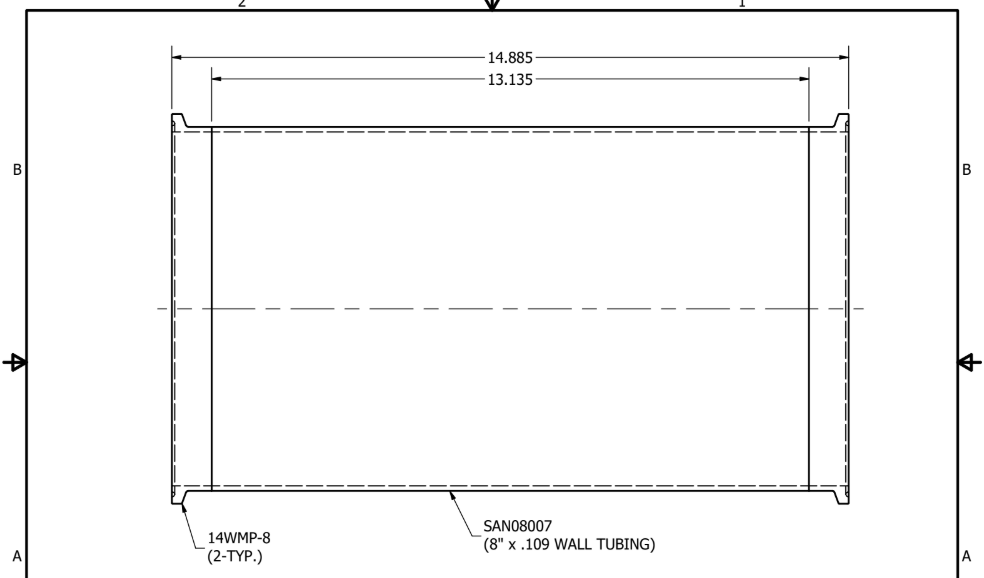

Below are some images of items we have fabricated for customers:

Pictured: Custom Tri-Clamp Manifold with 15 Spaces

Pictured: Custom Tri-Clamp Spool Assembly

Pictured: Custom Double-Bend Elbow Piece