When it comes to fluid control in industrial systems, selecting the right valve type is crucial to maintaining efficiency, safety, and process reliability. Two common valve types that professionals encounter are check valves and diaphragm valves. While both play key roles in managing flow, they operate in fundamentally different ways and are suited for distinct applications. Understanding the differences between these two valve types can help manufacturers make informed decisions that optimize their system’s performance.

Check Valves: Protecting Your System Against Backflow

Check valves are designed to allow fluid to flow in only one direction. These valves automatically prevent reverse flow, which can be critical in protecting equipment, maintaining pressure, or preventing contamination in sensitive systems. Check valves are typically simple in design and don’t require manual operation, making them a reliable option in scenarios where consistent, unidirectional flow is needed.

The key benefits of check valves include:

- Automatic operation: Since check valves do not require external actuation, they are ideal for systems where manual intervention is undesirable or impossible.

- Backflow prevention: By blocking reverse flow, they protect pumps, pipelines, and other critical equipment from damage caused by backpressure.

- Low maintenance: With fewer moving parts compared to other valve types, check valves generally require less upkeep, especially in systems with clean or non-abrasive media.

When to use check valves:

- Systems requiring backflow prevention to protect equipment, such as in pump discharge lines.

- Processes where automatic flow control is beneficial and manual intervention is not feasible.

- Applications in water treatment, chemical processing, and sanitary systems where hygiene is critical and reverse contamination must be avoided.

Looking for more in-depth information regarding different types of check valves? Read our blog post, “Understanding the Different Kinds of Check Valves“.

For more information on check valves, including various models suitable for sanitary applications, check out the check valve selection here.

Diaphragm Valves: Precision Flow Control with Sanitary Benefits

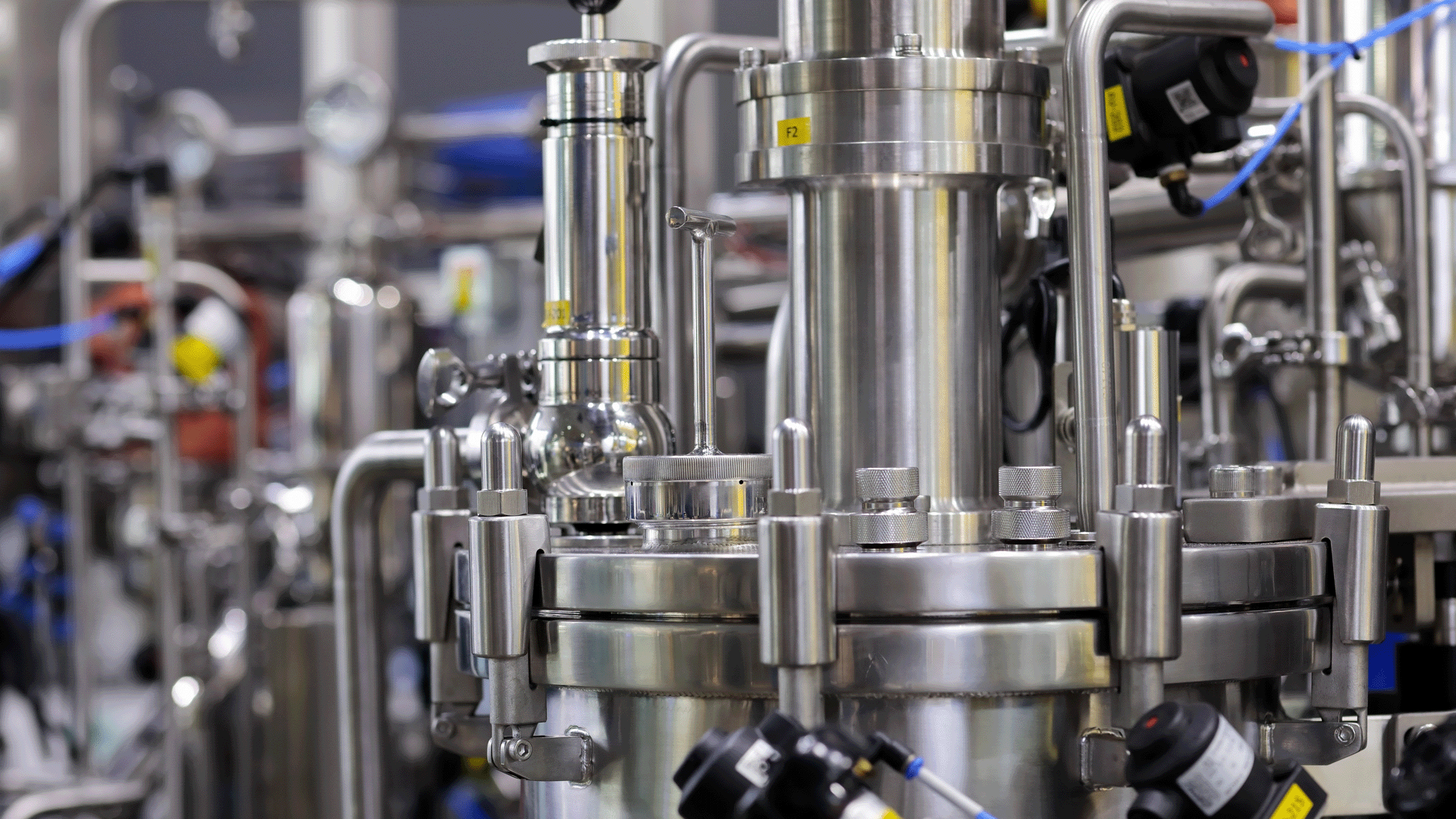

Diaphragm valves, on the other hand, are designed for precise flow control and are highly favored in industries where cleanliness and hygiene are paramount, such as in pharmaceutical, food and beverage, and biotechnological processing. These valves use a flexible diaphragm that comes into contact with the valve seat to either restrict or permit fluid flow. This design ensures that the media only contacts the diaphragm and the valve body, reducing contamination risk and making diaphragm valves ideal for sanitary processes.

The key benefits of diaphragm valves include:

- Superior hygiene: With minimal crevices and the media confined to a small portion of the valve, diaphragm valves are a top choice in applications where preventing contamination is critical.

- Accurate flow control: Diaphragm valves offer excellent throttling capabilities, allowing operators to fine-tune flow rates more effectively than with other valve types.

- Versatility: These valves can handle both viscous and particulate-laden fluids, making them versatile for a wide range of applications.

When to use diaphragm valves:

- Applications requiring high levels of cleanliness, such as in the food, pharmaceutical, and bioprocessing industries.

- Situations where precise flow control is needed, especially when handling sensitive or viscous fluids.

- Systems where ease of cleaning and sterilization are essential to maintain process integrity.

If you’re looking for sanitary, high-performance valves for your hygienic processes, explore the diaphragm valve options here or if you’re looking for specific information regarding diaphragm valves, read our blog post, “Introducing TOP-FLO® BioPro® Forged Diaphragm Valves“.

Key Considerations When Choosing Between Check and Diaphragm Valves

While both valve types have distinct advantages, the decision between check valves and diaphragm valves depends largely on the specifics of your application:

- Backflow Protection vs. Flow Control: If preventing backflow is your main concern, check valves are the better option. However, if you need precise control over the amount of flow, especially in sanitary processes, diaphragm valves are likely the right choice.

- Maintenance Requirements: Diaphragm valves generally require more maintenance due to the flexible diaphragm’s wear over time, especially in high-cycle applications. Check valves, on the other hand, are low-maintenance but might require attention in systems where debris or fouling could impair the automatic sealing mechanism.

- Sanitary Applications: Diaphragm valves shine in hygienic processes due to their design, which minimizes the risk of contamination. While check valves can be used in sanitary applications, they do not offer the same level of cleanliness and control as diaphragm valves.

- Fluid Characteristics: Check valves are typically more straightforward for clean fluids and unidirectional flow, while diaphragm valves handle complex fluids, including those with solids or high viscosity, much better.

Conclusion

Understanding the unique attributes and best-use cases of check valves and diaphragm valves is essential for optimizing your industrial processes. While check valves provide a robust solution for backflow prevention and automatic operation, diaphragm valves excel in sanitary, precise flow control applications. By assessing the specific needs of your system, including maintenance requirements, fluid characteristics, and sanitation priorities, you can select the valve that best meets your operational demands.

Whether you’re in the market for reliable check valves or diaphragm valves, partnering with a trusted supplier can help you ensure the longevity and efficiency of your equipment.