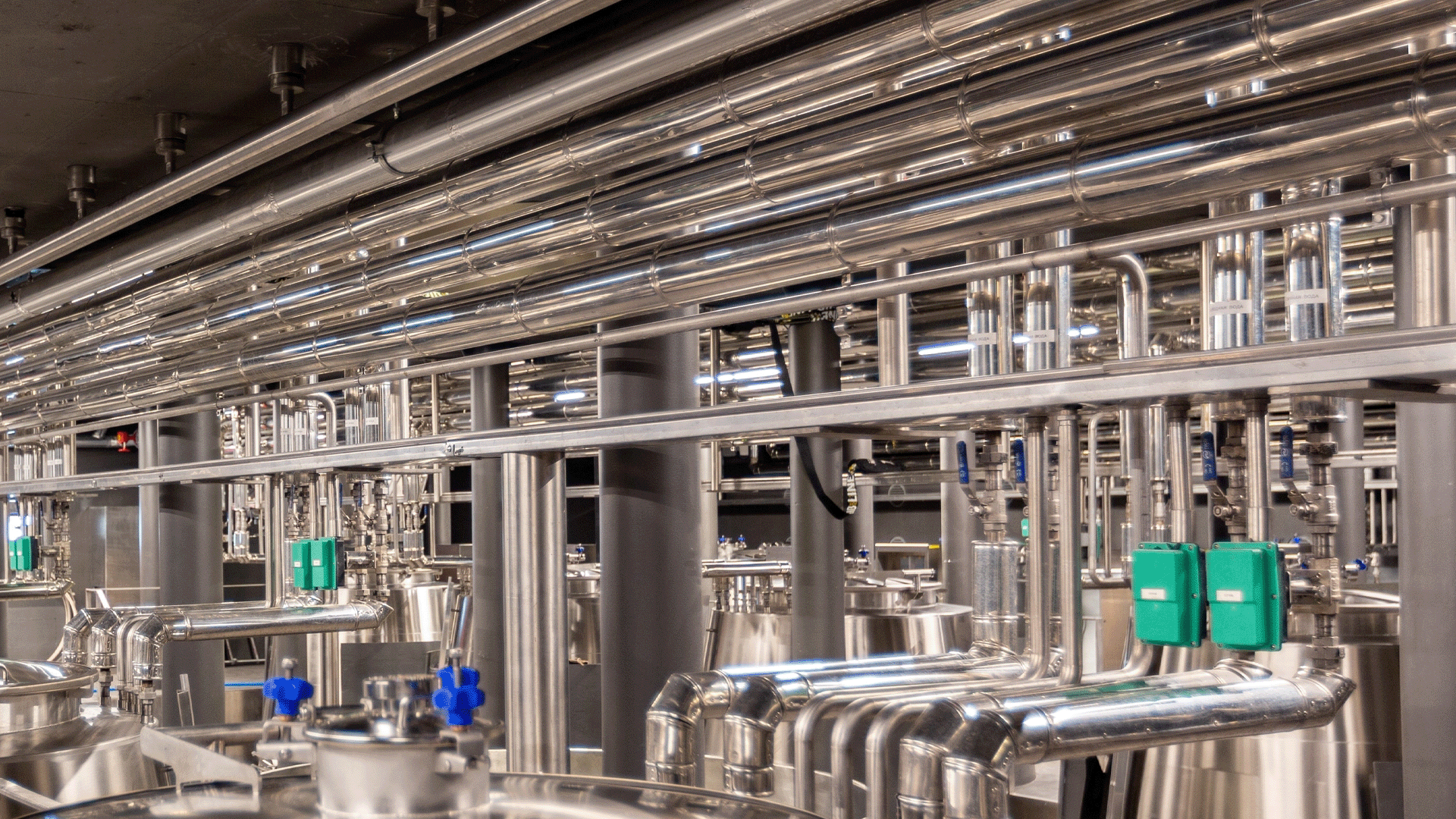

When it comes to designing and optimizing sanitary process systems, selecting the right components can make all the difference. Two commonly used sanitary tubing options are tri-clamp spool assemblies and stainless steel sanitary tubing. While these products share some similarities, they serve different purposes depending on the requirements of your process line. Here, we’ll explore their similarities, differences, benefits, and typical applications to help you make an informed decision.

We also offer tri-clamp spool assemblies and stainless steel sanitary tubing, with options from 15Ra to 32Ra, for use in BioPharm (BPE) processes.

Similarities Between Tri-Clamp Spool Assemblies and Stainless Steel Sanitary Tubing

Both tri-clamp spool assemblies and stainless steel sanitary tubing are:

- Constructed from Stainless Steel: Both products are typically made from 304 or 316 stainless steel, ensuring corrosion resistance, durability, and compliance with sanitary standards.

- Designed for Cleanliness: They meet stringent sanitary requirements, making them suitable for applications where hygiene is critical.

- Customizable: Both can be fabricated in various lengths, diameters, and configurations to meet specific process requirements.

- Versatile: They are widely used across industries that require sanitary equipment, such as food and beverage, pharmaceuticals, biotechnology, and cosmetics.

Key Differences Between the Two Products

- Design and Functionality:

- Tri-Clamp Spool Assemblies: These are pre-assembled sections of tubing fitted with tri-clamp ferrules on either end. They are designed for quick and easy connections, enabling modular system design and effortless disassembly for cleaning or replacement.

- Stainless Steel Sanitary Tubing: This refers to plain lengths of tubing without pre-attached fittings. It is often cut and welded into place, offering a seamless and permanent connection.

- Ease of Installation:

- Spool assemblies are ideal for systems requiring frequent disassembly or modifications, thanks to their tri-clamp connections.

- Sanitary tubing requires skilled labor for installation, as it often involves welding and polishing to ensure a smooth, sanitary finish.

- Flexibility:

- Spool assemblies offer more flexibility in reconfiguring process lines.

- Tubing provides a more rigid and permanent setup, suitable for fixed systems.

When to Use Tri-Clamp Spool Assemblies

- Applications with Frequent Cleaning: The ease of disassembly makes them perfect for CIP (clean-in-place) or SIP (sterilize-in-place) systems.

- Processes Requiring Modular Systems: They allow for quick changes or upgrades to process lines.

- Small to Medium-Scale Operations: Ideal where processes change frequently or where there is a need to quickly replace components.

Benefits of Tri-Clamp Spool Assemblies

- Quick installation and disassembly

- Minimal downtime during maintenance

- Enhanced flexibility for reconfiguration

- No specialized tools required for assembly

When to Use Stainless Steel Sanitary Tubing

- Permanent Installations: Best for long-term systems that don’t require frequent reconfiguration.

- High-Pressure Applications: Seamless tubing can handle higher pressures than connections reliant on clamps.

- Large-Scale Operations: Ideal for systems that benefit from a rigid and durable structure.

Benefits of Stainless Steel Sanitary Tubing

- Seamless and smooth interior for optimal product flow

- Lower risk of leaks due to welded connections

- High durability under pressure and extreme conditions

- Aesthetically clean and professional finish

Common Industrial Uses and Applications

Tri-Clamp Spool Assemblies

- Food and Beverage: Used in brewing, dairy production, and bottling lines.

- Pharmaceuticals and Biotech: Ideal for systems with strict cleaning protocols.

- Cosmetics: Common in modular production systems requiring frequent product changes.

Stainless Steel Sanitary Tubing

- Pharmaceuticals: Used in large-scale production facilities for sterile environments.

- Chemical Processing: Suitable for high-pressure or high-temperature systems.

- Dairy and Food Production: Ensures long-term reliability in fixed pipelines.

Conclusion

Both tri-clamp spool assemblies and stainless steel sanitary tubing are indispensable in sanitary process systems, but their suitability depends on your specific needs. For modularity and ease of maintenance, tri-clamp spool assemblies are an excellent choice. For permanent, high-pressure systems, stainless steel sanitary tubing is the way to go. Assessing your industry requirements, system scale, and maintenance preferences will guide you to the right product for your process line.