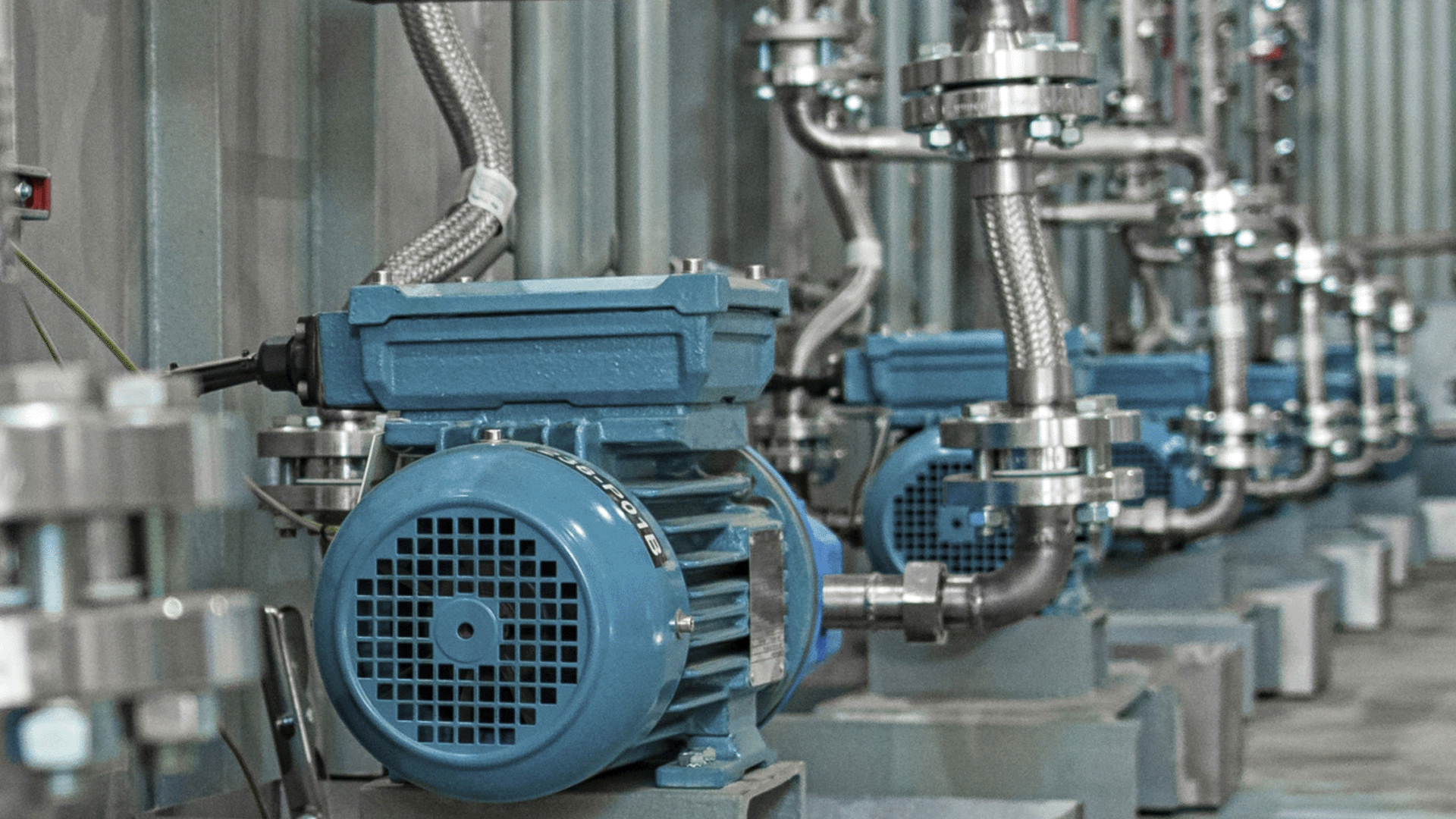

For applications that require sanitary centrifugal pumps, ensuring consistent performance and reliability is essential. One of the key metrics for evaluating pump performance is the Mean Time Between Failures (MTBF). A high MTBF indicates that a pump is operating efficiently and reliably over extended periods, reducing downtime and maintenance costs. Regular maintenance plays a critical role in achieving and maintaining a high MTBF. Let’s dive into why regular upkeep is essential and how investing in quality replacement parts and repair kits can make a significant difference.

Why Regular Maintenance Matters

- Preventative Care Reduces Unplanned Downtime: Regular maintenance helps identify potential issues before they escalate into major problems. By performing routine checks and servicing your pumps, you can address minor wear and tear, preventing unexpected breakdowns. This proactive approach is crucial in maintaining a high MTBF, as it reduces the likelihood of unplanned downtime that can disrupt operations.

- Extended Equipment Life: Proper maintenance ensures that your sanitary centrifugal pump operates within its optimal parameters. Regularly replacing worn parts and seals prevents excessive strain on the pump, thus extending its operational life. Components like pump seals and bearings are critical to the pump’s function, and their degradation can lead to increased wear on the pump’s other parts.

- Consistent Performance: Sanitary pumps are designed to handle delicate and often critical processes. Regular maintenance ensures that the pump performs consistently, maintaining the quality and safety of the fluids being processed. This consistency is crucial in industries where contamination or product quality can have serious consequences.

Key Maintenance Components and Products

- Pump Seal Repair Kits: Seals are essential in preventing leaks and maintaining the integrity of the pump system. Over time, seals can wear out or become damaged. Regular inspection and replacement of seals are vital for preventing leaks and ensuring the pump operates efficiently. Products like the Sanitary Pump Seal Repair Kits provide the necessary components to keep your seals in top condition. These kits often include various seal types and sizes to match different pump models, ensuring you have the right parts for effective maintenance.

- Pump Replacement Parts: Besides seals, other components such as impellers, bearings, and gaskets can wear out over time. Regular replacement of these parts is essential for maintaining the pump’s efficiency and reliability. The range of Sanitary Pump Replacement Parts includes high-quality components designed to fit various pump models. Investing in genuine replacement parts helps maintain the pump’s performance and contributes to a higher MTBF.

Implementing a Maintenance Schedule

To maximize MTBF through regular maintenance, consider implementing a structured maintenance schedule. This schedule should include:

- Routine Inspections: Regularly check the pump for any signs of wear or leakage.

- Scheduled Replacements: Replace seals, bearings, and other components at recommended intervals.

- Performance Monitoring: Keep track of the pump’s performance metrics to identify any deviations that may indicate potential issues.

Conclusion

Regular maintenance of sanitary centrifugal pumps is essential for increasing Mean Time Between Failures (MTBF). By incorporating preventive care practices and investing in high-quality repair kits and replacement parts, you can significantly enhance your pump’s reliability and efficiency. For top-notch components and kits, explore our range of Sanitary Pump Seal Repair Kits and Sanitary Pump Replacement Parts. Prioritizing maintenance not only prolongs the life of your equipment but also ensures that your operations remain smooth and uninterrupted.

Sanitary Fittings is proud to offer a full line of centrifugal pumps, pump and motor combos, valves, and actuators with our TOP-FLO® Ready-To-Go program. We also offer a popular guide on how to calculate pump flow rate.