Thermowells are critical components in temperature measurement systems, serving as protective housings for temperature sensors in industrial applications. Among the many thermowell designs available, Lagging Thermowells and Standard Thermowells cater to specific operational needs. Understanding their differences, applications, and benefits is essential for selecting the right solution for your sanitary processes. In this post, we’ll explore these two styles and guide you on when to use each.

What is a Standard Thermowell?

Standard Thermowells are the most commonly used type. They are directly installed into the process media, offering reliable protection for the temperature sensor against high pressure, corrosive environments, or mechanical forces. These thermowells are straightforward in design, often crafted from stainless steel or other corrosion-resistant materials to ensure longevity in demanding applications.

Benefits of Standard Thermowells:

- Ease of Installation: They are typically simpler to install due to their direct immersion in the process media.

- Fast Response Time: Since the sensor is closer to the process media, standard thermowells allow for quicker temperature readings.

- Cost-Effectiveness: Their straightforward design makes them a cost-effective solution for many applications.

Common Applications for Standard Thermowells:

Standard thermowells are ideal for sanitary processes where direct immersion is acceptable. Industries and applications include:

- Food and Beverage: Monitoring fermentation tanks, pasteurization systems, or brewing processes.

- Pharmaceuticals: Temperature control in bioreactors or sterile environments.

- Dairy Processing: Ensuring precise temperature measurements in milk pasteurization or cheese production.

What is a Lagging Thermowell?

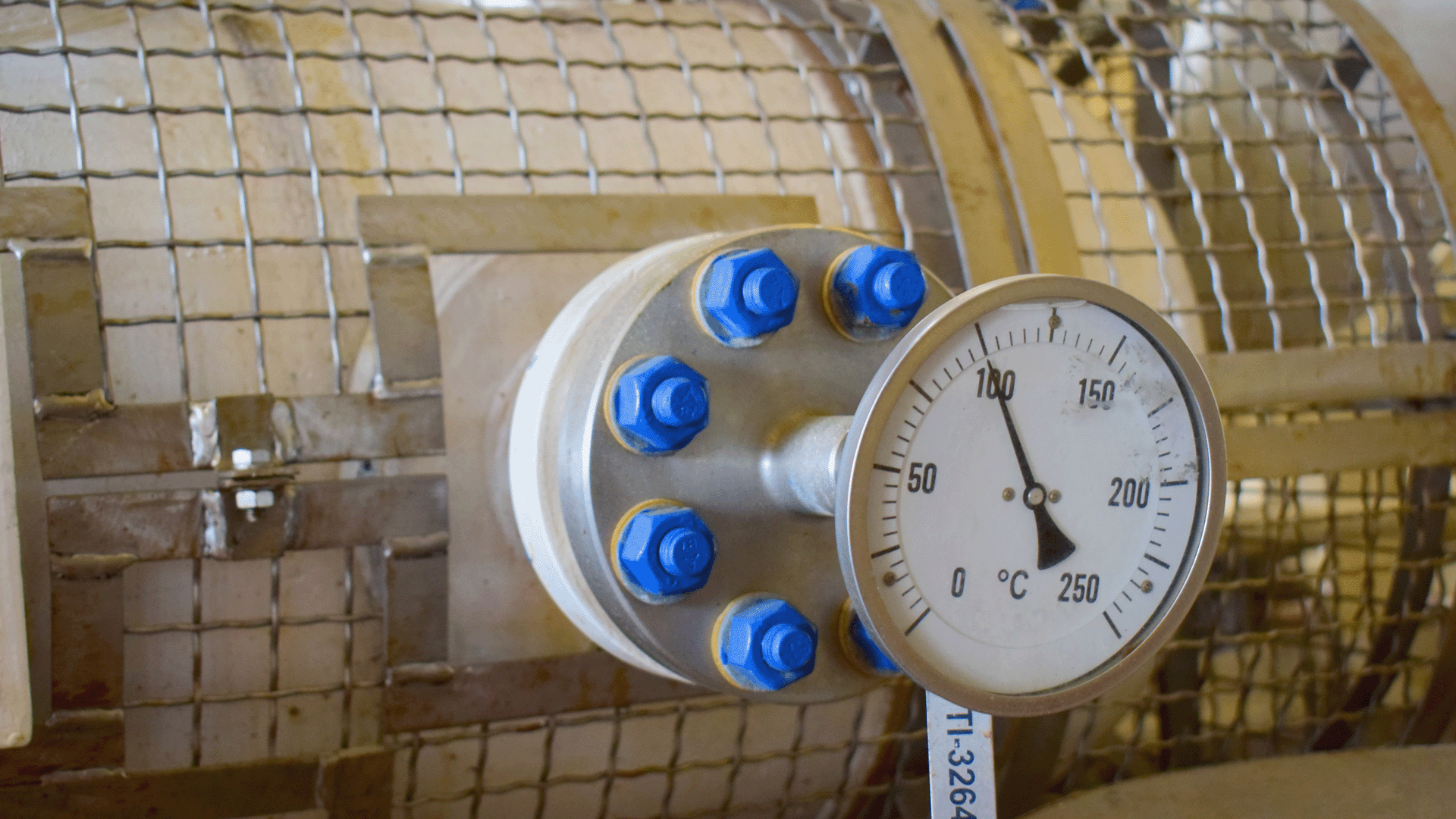

Lagging Thermowells are designed for applications involving insulated systems or lagging layers, which are common in processes requiring temperature stability or safety from extreme conditions. These thermowells include an extended neck to bridge the insulation layer, ensuring accurate temperature measurements without compromising the insulation.

Benefits of Lagging Thermowells:

- Maintains Insulation Integrity: The extended neck design allows the sensor to be installed without disturbing the insulation layer.

- Enhanced Safety: Protects against extreme process temperatures and minimizes heat transfer to external components.

- Versatile Installation: Suitable for both horizontal and vertical installations in heavily insulated systems.

Common Applications for Lagging Thermowells:

Lagging thermowells are suited for industries where insulation is critical. Applications include:

- Chemical Processing: Monitoring temperature in reactors or pipelines with heat preservation.

- Oil and Gas: Ensuring accurate readings in insulated pipelines or storage tanks.

- Energy and Power: Measuring temperatures in steam systems or boilers where insulation reduces energy loss.

Choosing the Right Thermowell for Your Process

When deciding between a standard thermowell and a lagging thermowell, consider the following factors:

- Insulation Requirements: Use lagging thermowells when processes involve insulation layers to prevent heat loss.

- Response Time Needs: Opt for standard thermowells when fast response time is critical.

- Process Environment: Evaluate the temperature, pressure, and corrosive nature of the media to ensure compatibility.

- Sanitary Standards: Ensure compliance with industry-specific sanitary requirements, such as FDA or 3-A standards, especially in food and pharmaceutical applications.

Conclusion

Both lagging thermowells and standard thermowells serve vital roles in temperature measurement across various industries. Standard thermowells excel in direct immersion applications, offering simplicity and fast response times. Lagging thermowells, on the other hand, shine in insulated systems, preserving process stability and safety. By understanding your specific process requirements, you can select the thermowell style that ensures optimal performance and reliability in your operations.

For more information or assistance in choosing the right thermowell for your application, contact our experts today.