TF-C114 Centrifugal Pump

- TOP-FLO® TF-C114 Centrifugal Pumps (3-A)

- Available Motor Frame Sizes (Sold Separately): 056C, 143TC/145TC

- Capacity: 10gpm to 125gpm *

- Pressure: 31 PSIG / 71.5 Foot of Head *

- Viscosity: 200 cp

- Temperature: 212° F

- Pump Head / Motor Combinations are available. Please contact us.

- Operation, Maintenance & Parts List

*See attached pump curves for flow capacities

The TOP-FLO® TF-C114 centrifugal pump is ideal for use in small and medium-size process applications in the dairy, food, beverage, pharmaceutical, and other sanitary process industries.

TF-C114 Centrifugal Pump Capacity Curves

C114 2X1.5 3500 RPM Capacity Curve

C114 2X1.5 1750 RPM Capacity Curve

C114 1.5X1.5 3500 RPM Capacity Curve

C114 1.5X1.5 1750 RPM Capacity Curve

TF-C114 Centrifugal Pump Attributes

- Pump Casing: Volute Type

- Pump Connections: Tri-Clamp

- Pump Construction materials: All Wetted Parts – Type 316L balance Type 304, Carbon Seal, O-Ring & Casting Gasket – FDA Buna

3-A Approved - Pump Finish: 32Ra Standard, Polished

- Pump Impeller: Max 4.000” Diameter

- Pump Seal: External Balanced, Sanitary Single Mechanical

How to correctly position the drive collar on a Top Line sanitary centrifugal pump

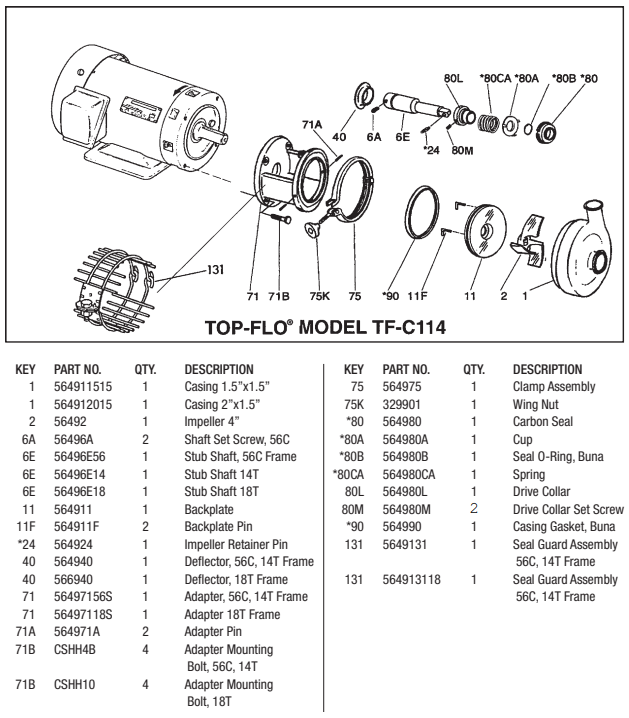

TF-C114 Centrifugal Pump Parts Diagram

Common Sanitary Pump Applications and Seal Materials

| APPLICATION | SEAL TYPE | SEAL MATERIAL |

|---|---|---|

| Beer | D | BUNA |

| Canola Oil | DG | FKM (Viton) |

| CBD Oil | DG | FKM (Viton) |

| Ethylene Glycol | DG | FKM (Viton) |

| Milk | D | BUNA |

| Propylene Glycol | DG | FKM (Viton) |

| Sodium Hydroxide | DG | FKM (Viton) |

| Wort | DG | FKM (Viton) |

| Water | D | BUNA |

| Distilled Spirits | DG | FKM (Viton) |

| Wine | DG | FKM (Viton) |

Additional information

-

What is the difference between DG and D?

-

Q What is the difference between DG and D?There are no answers for this question yet.

Is it possible to set this up for 120v 60hrz?

-

Q Is it possible to set this up for 120v 60hrz?A Yes. This pump can work with that sized motor.

Do you have spare parts for pump TF-C114 like Stub shaft, impeller, drive collar, carbon seal, spring, o ring seal Viton, deflector, Impeller pin , mechanical(DG seal) assembly (conversion kit). Thanks

-

Q Do you have spare parts for pump TF-C114 like Stub shaft, impeller, drive collar, carbon seal, sp...... Read moreA

Attached are the spare parts that we can offer for pump replacement kits.

What is the power requirement for this pump?

-

Q What is the power requirement for this pump?A The power requirement is based off the application. Please see our attached capacity curves for more reference. The capacity curves are based upon water as the medium being processed.