Centrifugal pumps are one of the most commonly used pieces of equipment and have an ever-expanding field of application. Like all equipment, these pumps also need their fair share of care and maintenance to keep them running in tip-top shape.

But with all these new applications, it’s not always possible to foresee problems that may turn up in the future.

As such, your best bet at keeping your centrifugal pumps running smoothly, and avoiding costly repairs rests on your ability to learn about your pump, and its parts so you can get ahead of any unpleasant surprises.

But where do you turn to for this information? Perhaps a quick search on the internet? Quora?

You can rest easy because you are in just the right place for exactly the information you need to start down the right path.

We’ve done all the leg work, so you don’t have to, and compiled this list of 6 must-know technical terms you’ll need to successfully care for your centrifugal pump.

We also understand the demands of operating and maintaining a centrifugal pump, so in addition to definitions, we’ve thrown in a few extra tips to help improve your operational efficiency and prolong your pump’s life.

Join us as we explore:

- Terms you’ll need to know to care for your pump and related systems

- Preventative measures you can take to avoid damage and downtime

- Tips to help expedite your troubleshooting if you ever run into trouble

Best of all, after the terms and expert tips, we’ll tell you where to find the best centrifugal pump care so you know exactly who to call to elevate your pump maintenance and optimize your operation.

Let’s dive straight in.

Term 1: The Impeller

The impeller is the component in a centrifugal pump that transforms rotational energy into kinetic energy by accelerating fluid and creating the pressure differential responsible for fluid movement.

You probably recognize the impeller as the propeller-looking part of your pump. When it rotates, it creates a centrifugal force (thus centrifugal pumps), that forces the fluid to the outer edges of the pump casing, and away from the impeller’s center.

This creates a pressure differential, with the low pressure at the center of the impeller causing more fluid to be drawn into the pump.

Impellers are available in various types, depending on their vane designs, which dictate their flow rate and head. These include:

Closed impellers

These are popular options for handling viscous fluids thanks to their high efficiency. The impeller blades or vanes typically feature a curved design to help guide fluid in a specific direction. This design is part of what contributes to closed impellers’ efficiency.

Additionally, the impeller blades connect to a hub and back disk forming a smooth surface that encourages fluid movement. However, the blades are completely enclosed within the pump casing so they don’t come into contact with the fluid being pumped.

This complete enclosing of the vanes helps protect your pump impeller and prolong its lifespan because typically they are used in applications where the pump fluid is abrasive, and sometimes even contains solid particles.

Open impellers

Open impellers feature a design where the impeller blades are exposed to the fluid being pumped. This allows the fluid to flow through the spaces between the blades reducing efficiency compared to closed impellers.

The open design also means that the impellers are only used in applications where the pumped fluid has a low viscosity and does not contain any abrasive or solid particles.

An open impeller design usually consists of a central hub, to which the blades are attached, and the pump impeller, which is mounted on a shaft that drives it.

While open impellers might not be as efficient, they make up for it with their ease of cleaning and maintenance.

Semi-open impellers

These feature a design that blends elements of both the closed and open impeller. Semi-open impellers have their blades partly enclosed within the pump casing while leaving the other part exposed to the pumped fluid.

This design allows semi-open impellers to take advantage of the best qualities of open and closed impeller designs while mitigating some of their disadvantages.

For instance, semi-open impellers are more efficient than open impellers thanks to the reduced fluid recirculation within the pump. However, they are still less efficient than closed impellers.

Semi-open impellers are used in applications where the pumped fluid is somewhat abrasive or contains some solid particles, and high efficiency is needed.

This configuration accommodates both viscous and less viscous fluids with a moderate head.

Vortex impellers

These are different from the other kinds of impellers used in centrifugal pumps because their blades are designed such that they create a vortex in the pumped fluid.

Vortex impeller pumps contain a recessed central cavity or “eye” and a set of curved blades that extend from the center of the impeller disk.

When the impeller rotates, the blades generate a vortex that draws the fluid toward the center of the impeller and pushes it out through the pump discharge.

Vortex impellers are ideal for fluids containing solids, fibers, or debris because the vortex helps prevent clogging and damage to the impeller.

However, the energy it takes to generate the vortex makes pumps that use vortex impellers less efficient than the other options.

When choosing an impeller, factors such as flow rate, head requirement, fluid type, and overall pump efficiency must be considered for the following reasons:

- Optimal performance: Selecting the right impeller will help ensure that your pump delivers peak performance and meets your flow rate and head requirements while minimizing energy consumption.

- Enhanced reliability: The right impeller for your pumped fluid will reduce the likelihood of impeller damage or clogging, thereby improving your pump’s reliability and reducing downtime.

- Pump longevity: The right impeller for your pumped fluid and system requirements will reduce wear and tear on pump components, ultimately extending your pump’s lifespan.

- Energy efficiency: By choosing an appropriate impeller for your specific application, you optimize your energy usage and lower your operational costs reducing your environmental impact.

- System compatibility: The right impeller also ensures compatibility within your system. This means reduced chances of issues such as cavitation, vibrations, and overloading, which will harm your pump and the broader system.

We cannot overstate the importance of finding the right impeller. As we’ve seen, an impeller dictates your pump’s performance, and energy consumption, even the durability of your system.

Learn More: Our previous article goes into more depth on the different types of pump impellers.

To ensure the optimal performance of your system, it’s essential to collaborate with a knowledgeable and reliable supplier to provide guidance on the best impeller for your needs.

For that, who better than Sanitary Fittings—your one-stop partner for all things pumps, parts, and stainless steel fitting solutions?

Term 2: Head

Head is a measure of the energy in a fluid resulting from pressure, velocity, and elevation. Head is one of the key parameters used to determine a centrifugal pump’s capacity to propel a fluid to a specific height or pressure.

You can think of it as the pressure required to sustain the fluid flow rate within your system.

However, its units of measurement vary based on application, the pumped fluid’s specific gravity, and your pump’s characteristics. However, the most commonly used unit to represent pump head is feet (or meters if you prefer metric).

In certain applications, head and pressure are used interchangeably and measured in psi or bar.

But no matter your application, understanding head is crucial for operating centrifugal pumps. You see, head will impact your operations, performance, and efficiency in several ways, including:

- Pump selection: Head is one of the key features you should consider when picking the perfect pump for your operations.

A suitable pump must generate enough head to overcome the system’s static head and friction losses, to ensure optimal fluid flow and performance.

Static head refers to the height difference between your fluid source and discharge point, while friction losses arise from fluid movement through the stainless steel tubing, pipes, and fittings.

Overlooking these factors can result in incorrect pump selection, cavitation, and mechanical failure. - Matching performance curves: Head generated depends on your impeller diameter, speed, and fluid flow rate.

To achieve the desired flow rate and head, your pump’s performance curve must align with the system curve—a feat you’ll have better success at achieving when you understand your head requirements.

When the two curves match, your pump will operate at its best efficiency point (BEP), maximizing energy efficiency and prolonging the pump’s life. - Preventing cavitation: Insufficient head will lead to cavitation—a phenomenon where bubbles form and collapse within the pump, causing noise, vibration, and even component damage.

Ensuring optimal pump head will help prevent cavitation by ensuring your pump runs within its recommended range. - System efficiency: Understanding head enables you to evaluate the efficiency of your entire system and empowers you to address any sources of head loss, including friction and elevation changes.

This puts you in a better position to optimize your system efficiency and reduce energy consumption. - Troubleshooting problems: Understanding head will help you identify and mitigate issues, such as pressure fluctuations, changes in fluid flow, and system inefficiencies.

This knowledge especially comes in handy when diagnosing and resolving problems quickly, ultimately minimizing your downtime and maintenance costs.

Clearly, understanding head is essential for successful centrifugal pump operation. This knowledge will impact just about everything facet of your system from pump selection through to maintenance.

Don’t take chances and risk catastrophic system failures or damage to your pump. If you need help establishing the perfect head for your operations or picking the best pump components to optimize your system, look no further than Sanitary Fittings.

At Sanitary Fittings, our team of experts is always close at hand to help with any of your stainless steel centrifugal pump questions and components.

As Rob Mozur can attest, our representative Brand, answered all his questions with a “high degree of knowledge and professionalism.” This is the same level of attention we guarantee all our partners, in addition to our full might and experience in the sanitary pump world.

“Your company was a joy to deal with. The website was very easy and straightforward to navigate, as I placed my initial order online. Thank you and keep up the great work!”

Fun Fact: When the pump head is zero, fluid flows at its maximum rate. The pump’s energy is solely focused on moving the fluid rather than lifting it in this case, hence resulting in faster flow.

Term 3: NPSH

Net Positive Suction Head (NPSH) is a critical term in centrifugal pump operation, representing your pump’s absolute pressure minus the liquids vapor pressure, and is expressed in height.

NPSH is so essential because it indicates whether your pump is prone to cavitation or not.

Common causes of NPSH issues include insufficient NPSH available, which may be a result of low suction pressure, overly hot liquid, or excessively high impeller speeds.

Another common cause may be NPSH margin, that is, the difference between available and required NPSH, where a low margin can lead to cavitation.

Your understanding of NPSH can significantly impact your ability to ensure optimal performance and reliability of your pump system. So how about we take a closer look into each of the instances mentioned above?

Insufficient NPSH available

As mentioned, there are three instances that can lead to insufficient NPSH, let’s explore each of them.

- Low suction pressure: When the pressure at your pump inlet is too low, it cannot prevent the pumped fluid from vaporizing. This significantly increases the risk of cavitation.

- Overly hot liquid: When your pumped high liquid is too hot, it will cause an increase in vapor pressure, reducing the NPSH available. A drop in NPSH below the required levels significantly increased the chances of cavitation.

- High impeller speed: When the impeller speed is too high, it can create a higher pressure drop at the pump inlet, reducing available NPSH. As the NPSH drops, the chances of cavitation rise.

NPSH margin

This refers to the difference between the available NPSH (represented by NPSHa) and the required NPSH (represented by NPSHr).

NPSHa refers to the NPSH present in the system, while NPSHr is the minimum NPSH needed to prevent cavitation.

A low NPSH margin can result from a number of factors, namely:

- Improper pump selection

- Inadequate system design

- Changes in operating conditions

When the margin is too low, then the available NPSH is barely sufficient or insufficient to meet your pump’s requirements, increasing the likelihood of cavitation.

Cavitation occurs when vapor bubbles form and collapse within the pump due to localized pressure drops, leading to potentially catastrophic damage to your sanitary pump.

To mitigate these issues, you must ensure proper pump selection, system design, and appropriate impeller speed, and who better to help ensure this than Sanitary Fittings? A team of tried and true experts who are happy to lend their expertise.

At Sanitary Fittings we understand how vital it is to mitigate any NPSH issues. As such we can help ensure proper design and sizing of your pump system, including the stainless steel tubing, hose fittings, valves and strainers to ensure optimal NPSH availability.

Here is a brief explainer on sizing our products:

We’ll also set you up with the right pump impeller and ensure the right speed based on your system requirements. If need be we can also recommend anti-cavitation devices like inducers and impeller trimming to further curb cavitation.

Understanding NPSH is key to maintaining optimal operation and avoiding problems in your centrifugal pump. By addressing NPSH concerns you ensure enhanced pump performance and reduce the risk of cavitation.

Get in touch with Sanitary Fittings for help getting ahead of any NPSH concerns.

Term 4: Cavitation

Cavitation refers to a phenomenon that occurs when vapor bubbles form in a liquid due to a drop in pressure below the liquid’s vapor pressure.

In a stainless steel centrifugal pump, cavitation is a major concern because as these bubbles collapse, they generate high-energy shockwaves that reduce pump efficiency, or worse, critically damage your pump.

The most common causes of cavitation in a centrifugal pump include:

- Exceeding your pump’s flow rate capacity: This can create a low-pressure area within the system, resulting in vapor bubble formation.

- High suction lift: When the suction lift is too high, the pressure at the pump inlet may drop below the vapor pressure, causing cavitation.

- Partially closed discharge valve: A partially closed discharge valve can increase the pressure drop across the pump, leading to cavitation.

- Inadequate submergence of your pump suction: This may cause air to be drawn into your pump, creating areas of low pressure that can trigger cavitation.

Thankfully, there are measures you can take to prevent cavitation. Here are a few of our most effective recommendations:

- Only operate the pump within its specified design limits for flow rate, suction lift, and net positive suction head (NPSH).

- Avoid sudden changes in flow rate to prevent abrupt pressure variations. These are a recipe for cavitation.

- Maintain proper suction and discharge conditions to ensure that your system stays within your pump’s design specifications and limitations.

- Keep your impeller surface smooth and free from corrosion or fouling. These can create localized areas of low pressure and trigger cavitation.

Cavitation presents a critical risk for your sanitary pump system. But understanding its causes and implementing preventive measures can altogether mitigate its risk.

For help assessing your cavitation risk, and implementing measures to prevent it, reach out to Sanitary Fittings at (800)-270-8926, and we’ll get set up with the best-suited centrifugal pump and parts to streamline your operation.

Bonus Tip: How do you calculate pump flow rate? This guide outlines three different methods and provides more insights.

Term 5: Mechanical Seals

Mechanical seals are an essential component in your centrifugal pump. They help prevent leaks between the pump casing and the rotating pump shaft through two distinct parts:

- The stationary part: which is typically made of ceramic or carbon materials and attached to the pump casing by a gland.

- The rotating part: which is typically made of carbon or stainless steel and connected to the pump shaft where it’s secured in place using a spring.

There are different types of mechanical seals, with the two most common variants being the single and double mechanical seals.

Single mechanical seals have one set of sealing surfaces while double mechanical seals have two sets of sealing surfaces and a barrier fluid between them.

Here are a few more seals and their areas of application.

| Type | Characteristics | Function |

| Single Seal | Consists of one set of sealing surfaces; used in most common applications. | Suitable for less demanding applications; provides adequate sealing performance for most common fluids. |

| Double Seal | Comprises two sets of sealing surfaces with a barrier fluid in between; used in applications with hazardous or abrasive fluids. | Offers enhanced sealing performance for hazardous or abrasive fluids, reducing the risk of leakage and environmental contamination. |

| Cartridge Seal | A pre-assembled unit with all components, making installation easier and more accurate. | Simplifies installation and alignment, improving reliability and reducing the risk of seal failure due to incorrect installation. |

| Split Seal | A mechanical seal is divided into two halves, allowing for easier installation and maintenance without disassembling the pump. | Allows for easier maintenance and reduced downtime, as the pump does not need to be disassembled for seal replacement or repair. |

The primary function of a mechanical seal is to prevent fluid from leaking out of your pump. This is crucial for ensuring worker safety and protecting the environment from potential contamination.

Maintaining the correct seal between stationary and moving parts in your system also helps maintain optimal pump performance.

But to achieve this, you need to ensure proper care and maintenance of your mechanical seal—which incidentally, is not a once-and-done type of thing.

Mechanical seal care starts with proper installation and involves regular checks and maintenance, and lubrication to prolong their life and prevent premature failure.

To help ensure the correct installation and maintenance of your mechanical seals contact Sanitary Fittings.

Our vast experience with sanitary pumps and associated parts, and eagerness to lend our expertise makes us a valuable resource at your disposal. Get in touch and together we will safeguard your pumps, the environment, and workers.

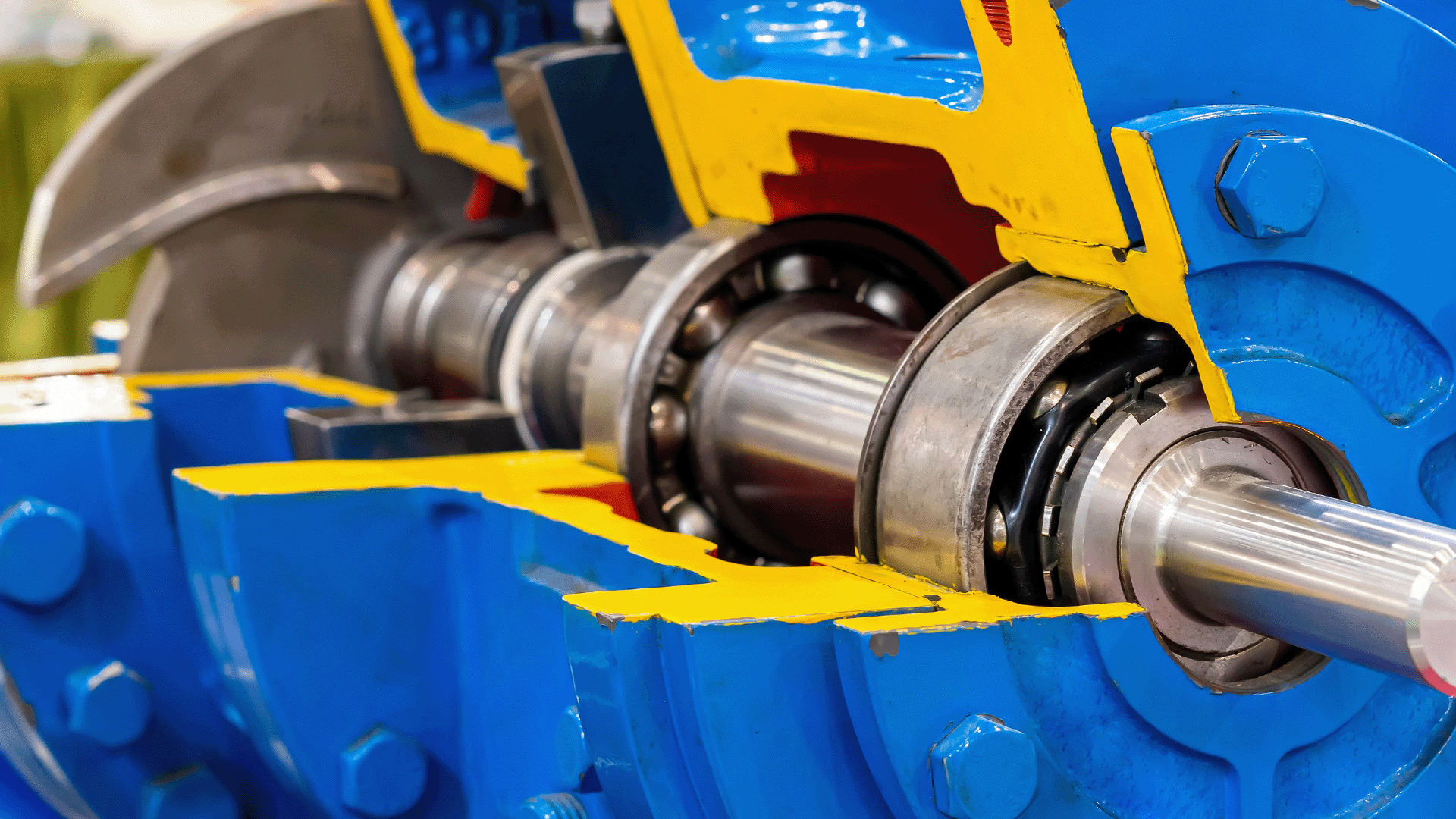

Term 6: Bearing

The bearings in centrifugal pumps play a crucial role in the functioning of your pump. Located on either end of the pump shaft, bearings help support the rotating shaft and ensure its smooth operation. They also reduce friction and absorb radial and axial loads on the shaft.

Given the vital role they play, ensuring proper maintenance of your bearings is essential for extending the life of your centrifugal pump.

But to do this effectively, first, you need to understand the different kinds of bearings, how they work, and how to care for them.

In a centrifugal pump, there are two primary types of bearings:

Journal bearings

These support the shaft’s radial loads and are typically located on the impeller side of the pump.

Journal bearings are available in two forms:

- Sleeve bearings: These, as their name implies, consist of a metal sleeve that fits tightly around the shaft, providing a solution for radial load support.

- Rolling element bearings: These feature balls or rollers that rotate around the shaft, reducing friction and mechanical wear.

Thrust bearings

These are found on the pump motor side where they support axial loads. Thrust bearings are classified into three types:

- Fixed geometry bearings: These are the most commonly used bearings in centrifugal pumps where they are used to support axial loads.

Fixed geometry bearings typically consist of a cylindrical sleeve around the shaft that holds a thin layer of lubrication between the shaft and sleeve.

The sleeve fits snugly within the bearing housing where it’s held in place usually using a locking ring. However, this means a reduced ability to compensate for changes in the pump shaft angle or handle high-speed rotations without overheating. - Tilting pad bearings: These have bearing pads that adjust and tilt according to the changes in the angle of the shaft which helps distribute the load evenly, reducing friction and wear on the shaft.

Tilting pad bearings are commonly used in high-speed applications where there is a lot of rotational force. - Magnetic bearings: These use electromagnets to levitate the shaft, eliminating contact, and thereby friction between the shaft and bearing surfaces.

As a result, magnetic bearings have lower maintenance costs, improved efficiency, and a longer lifespan. They are also able to handle high speeds and heavy loads without overheating or breaking down.

Bearing failure in a centrifugal pump can have catastrophic consequences on your pump.

When bearings fail, they can cause intense vibrations, increased noise levels, misalignment of the shaft, and potential damage to other pump components.

As such, it’s vital to regularly monitor your pump bearing conditions and perform preventative maintenance to avoid costly damage, and downtime.

Monitoring your pump’s bearing can involve techniques such as regular visual inspections for wear, debris, and leakage.

You can also conduct high-temperature and vibration checks, which indicate whether the bearings are functioning properly. For accurate readings, make use of conditional monitoring tools such as infrared thermography, vibration analysis, and acoustic emissions testing.

These will help you detect early signs of bearing failure and allow you the time you need to get ahead of them.

Preventing pump bearing and maintenance can also involve practices such as:

- Regular lubrication: This is essential for reducing friction and wear on your bearings and shaft. Check and replace your lubrication as per your manufacturer’s recommendations regularly.

- Alignment: Proper alignment of your pump motor is crucial for reducing stress on the bearings. Inspect and correct any misalignments regularly to avoid excessive loads, and possibly failure of your bearings.

- Cleaning: Keep the pump and surrounding area clean to prevent debris and other contaminants from getting into the bearing housing. Dust, dirt, and foreign particles will cause premature wear and reduce bearing life.

- Replacement: Timely replacement of worn-out bearings is the key to avoiding catastrophic failures. Stick to your manufacturer’s guidelines on bearing service life and replacement schedules.

- Load management: Do not load your pump beyond the recommended levels. Excessive loads will strain your bearings significantly shortening their lifespan and even causing catastrophic failure.

By understanding your pump bearings, and performing preventative maintenance, you significantly mitigate the risk of bearing failure, and in the long run, help ensure the longevity of your pump.

Of course, for optimum results and the ultimate performance and longevity of your pump and the overall system, you will need to put into practice all we’ve covered today and more.

At first thought, this might seem daunting—it is a lot of pump components to learn about and care for. But with the right partners, caring for your centrifugal pump, its parts, and your overall system can be a breeze.

This is where Sanitary Fittings come in. So here’s a quick look at who we are and how we can help you set up and care for your centrifugal pump systems.

Elevate Your Centrifugal Pump Performance With Sanitary Fittings

Steven Johnson, one of Sanitary Fittings’ customers once described his experience working with us as perfect. He got everything he needed, shipped on time, and all at a bargain. In his own words:

“My experience with Sanitary Fittings was perfect. They had the fitting I needed for a competitive price. Shipping was expeditious and the Stainless Steel products were well packed and protected. I would not hesitate to recommend Sanitary Products to anyone and everyone. I will buy from them again when the need arises.”

This is the experience we strive to give every single one of the people we work with.

At Sanitary Fittings, we understand the need for impeccable customer service in addition to the expertise and world-class stainless steel fittings we offer. We know that working with centrifugal pumps and related systems is high-pressure work, so we stove to help take the load off.

Call us on (800) 270-8926, or shoot us an email at sales@sanitaryfittings.us about your stainless steel fittings and centrifugal pump needs or queries, and like Steven, we’ll make sure your experience working with us is perfect.