Sanitary Centrifugal Pump: 3 Basic Facts You Should Know

Centrifugal pumps were the world’s 189th most traded product in 2020, due to their high demand for domestic and industrial use.

They have a basic design that doesn’t involve pistons or valves, and their moving components are few. The pump’s operation mainly relies on an impeller that rotates, creating centrifugal force that pushes the liquid forward.

Their basic design makes them easy to use, and they’re applied anywhere large volumes of low-viscosity liquids need to be transferred.

Though sanitary centrifugal pumps aren’t complicated, there are basic operation and maintenance facts that, if you’re aware of them, will save you time and money spent on repairs or replacements.

These helpful basic facts include:

- Cavitation breaks down your pump.

- Your pump needs regular alignment.

- Viscous liquids cause pump inefficiency.

1 – Cavitation Shortens Your Pump’s Lifespan

As the name implies, cavitation is the formation of cavities around a pump’s metal components, such as the impeller. Cast iron impellers are the most affected while steel ones are the least.

Cavitation happens when water vapor bubbles condense on metal. When the bubbles implode, they release latent energy astiny pressure-filled jets that strike nearby metal surfaces and eventually chips them away.

The impeller is often the first component to fail since cavitation takes place at the pump’s entrance, where the impeller is located.

A damaged impeller decreases the pump’s flow pressure, and the shock waves caused by the imploding vapor bubbles cause premature valve failure.

Eventually, the pump system breaks down.

So, what causes cavitation?

Very Low Pressure at the Pump’s Inlet

According to Bernoulli’s theorem, an increase in a liquid’s velocity decreases its pressure and vice versa. Therefore, a temporary increase in velocity drops the water pressure, which creates the ideal cavitation environment.

Boiling Water

At low temperatures, the water vapor pressure is low.

Pressure mounts with an increase in temperature until it reaches the boiling point, where the atmospheric pressure is the same as the vapor pressure. The boiling point is the optimal temperature for the destructive vapor bubbles to form.

Sourcing Water From a Sump (Suction Lift)

A suction lift increases the vertical distance from the water level in the sump to the pump. The increased vertical distance subtracts from the water’s static pressure, increasing the water’s ability to turn to vapor and form the damaging bubbles.

Is It Easy to Detect Cavitation?

Cavitation goes undetected if no one is close to the pump to hear the popping or rumbling sounds caused by the collapsing vapor bubbles—similar to moving gravel or coffee beans.

You can detect cavitation early by monitoring vibration levels caused by the collapsing vapor bubbles. A higher vibration frequency signals worsening cavitation.

Note: Cavitation is identified by vibration on both bearings, whereas vibration on one bearing might be a lubrication issue.

A good tool to use is a smart machinery health device that scans vibration changes, analyzes results, and gives off a warning. Combine monitoring with infrared imaging and lubricant analysis for better results.

To predict if your centrifugal pump will cavitate, check the pump’s net positive suction head required (NPSHr), which is how much absolute pressure is required to prevent cavitation.

The pump manufacturer provides the NPSHr.

Next, check the net positive suction head available (NPSHa), which is the absolute pressure available at the pump inlet.

Use this formula:

NPSHa = h1 + hss – hf – hvp

Where:

h1 is absolute pressure over the liquid.

hf is friction in the suction line.

hss is static head.

hvp is the liquid’s vapor pressure in the pump.

Note: hss is negative when there’s a suction lift.

To maintain a cavitation-free environment, NPSHa must be greater than NPSHr.

2 – Viscous Liquids Cause Pump Inefficiency

A sanitary centrifugal pump is suitable for liquids with a viscosity of up to 200 centipoises (cP).

As the liquid’s viscosity increases, the pump’s performance deteriorates due to increased resistance, which requires more pressure to maintain the liquid’s flow. Any liquid thicker than water starts challenging the centrifugal pump.

Liquids fall into two categories:

Newtonian liquids – maintain constant viscosity despite shear rate or agitation. Examples are water and alcohol.

Non-Newtonian liquids – are further divided into two:

- Shear thinning or thixotropic liquids – reduce their viscosity when mixed or agitated. Examples are paint and lotion.

- Shear thickening or dilatant liquids – increase their viscosity when mixed or agitated. An example is a mixture of cornstarch and water.

Centrifugal pumps are inefficient at pumping highly viscous fluids because of their inability to mix some materials and produce a shear-thinning effect. The lack of a thinning effect means viscosity isn’t reduced, so the pump will struggle to operate.

A few issues happen to a centrifugal pump when it pumps a viscous liquid:

- Reduced pump head and flow

- Increased brake horsepower requirements

- Reduced capacity

Generally, the pump’s efficiency is reduced.

The table below represents some substances and their viscosities:

| Liquid Type | Viscosity In Centipoise | Viscosity In Centistokes | Viscosity In Saybolt Universal Second |

| Water | 1.0 | 1.0 | 31.0 |

| Milk | 3.0 | 4.0 | 40.0 |

| Cream | 20.0 | 20.6 | 100.0 |

| Vegetable oil | 40.0 | 43.2 | 200.0 |

| Tomato juice | 180.0 | 220.0 | 1,000.0 |

| Glycerine | 800.0 | 1,100.0 | 5,000.0 |

| Honey | 1,500.0 | 2,200.0 | 10,000.0 |

| Mayonnaise | 5,000.0 | 6,250.0 | 28,000.0 |

Use a viscometer or a rheometer to determine a liquid’s viscosity. Once you know the viscosity of the liquid you’ll be pumping, make a pump selection.

A positive displacement pump is recommended for highly viscous liquids. It operates at a lower speed and lower shear rate than a sanitary centrifugal pump.

3 – Misalignment Checks Are Necessary

Image Source: Pump & Systems

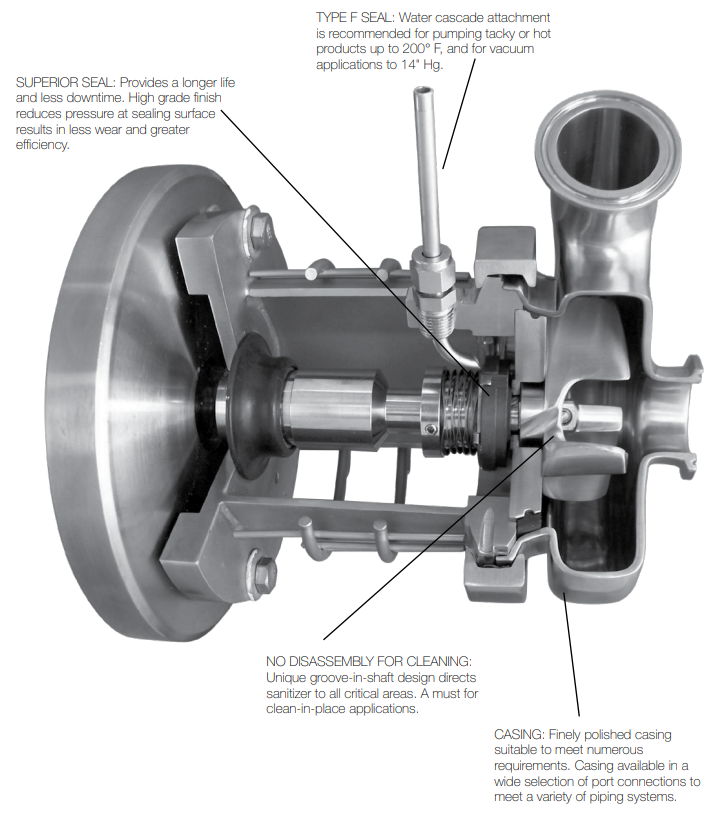

Misalignment is responsible for pump damage. Such damage includes worn-out bearings, seals, and shafts.

Misalignment can happen during these situations:

- Shipping – A sanitary centrifugal pump comes pre-aligned from the industry, but moving during the delivery process can alter its alignment.

- Incorrect mounting – If the base plate is not mounted firmly on the foundation, it will distort and cause the pump to move about, causing misalignment.

- Poor installation – If you don’t follow the instruction manual, your pump may end up with parallel or angular misalignment.

- “Soft foot” – A condition where one or more feet aren’t making proper contact with the frame’s foot points. The equipment rocks—undetectably or detectably (gross soft foot)—until it misaligns.

Misalignment also occurs when the couplings connecting the motor and pump shafts move out of place due to the pump’s vibrations.

There are three main types of couplings used:

- Rigid couplings – connect the pump and motor shafts firmly, but their seals can’t absorb vibrations when the pump is running, causing their bearings to misalign

- Flexible couplings – accommodate some vibrations and therefore protect the bearings to some extent from premature wear

- Magnetic couplings – connect the motor and pump using a magnet. Since there’s no mechanical connection, misalignment is not as common

Misalignment may still occur while using either of the three coupling types, because of the pump’s vibrations over a period of time.

How Do You Correct Misalignment?

For new pumps, don’t use them immediately after they’re delivered. First, check whether the motor and pump shafts are aligned well.

Do a routine checkup on already-installed pumps every three months because everything may appear normal only for motor torque and thermal stresses to occur.

Ensure the base plate is correctly mounted and anchor bolts are tight. Use a concrete foundation that’s three times the pump system’s mass.

If misalignment is motor-related, reposition the motor so that its shaft and the pump’s are center-aligned.

Use a laser measurement device to identify “soft foot” issues. The device measures minute changes in the pump and motor’s position during operation.

Note: If the pump or motor has been moved to a new location or repositioned in any way, check for misalignment.

These Sanitary Centrifugal Pump Facts Are Key to Increasing Your Pump’s Lifespan

A sanitary centrifugal pump is the most widely used pump but do you know some basic facts about its operation and maintenance that help prolong its lifespan?

Cavitation, misalignment, and pumping viscous liquids with a sanitary centrifugal pump will take a toll on your pump and lead to its premature demise.

Sanitary Fittings provides as much information as possible on how to take care of your sanitary pump. We strive to provide the best customer experience and were named in the 2022 Inc. 5000 List.

One of our satisfied customers shared this:

“Excellent customer service and great prices. It’s a pleasure doing business with Sanitary Fittings.”

– Kory Keene

We’d love to hear from you. Call us or send an email.

Share on LinkedIn: