Cap existing process line with male I-line end cap

I-Line fittings provide a rigid, leak-resistant seal, joining two separate tube fitting components. Available in both 304 Stainless Steel alloy, providing both strength and durability. This product is 3A certified for use inline process applications where sanitary conditions are a requirement.

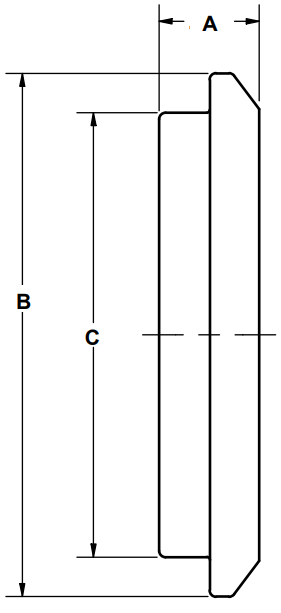

| Part Number | Size (inches) | A | B | C | |

|---|---|---|---|---|---|

| 16AI-14I-1 | 1" | 0.505" | Request Drawing | ||

| 16AI-14I-1.5 | 1 1/2" | 0.505" | Request Drawing | ||

| 16AI-14I-2 | 2" | 0.505" | 2.643" | 2.245" | |

| 16AI-14I-2.5 | 2 1/2" | 0.692" | 3.310" | 2.743" | |

| 16AI-14I-3 | 3" | 0.692" | 3.873" | ||

| 16AI-14I-4 | 4" | 0.755" | |||

| 16AI-14I-6 | 6" | 0.755" | 7.498" | 6.905" |

Additional information

Line Drawings

| SKU | Description | Line Drawing |

|---|---|---|

| 16AI-14I-1-304 | 1″ Male I-Line Solid End Cap 304 |

|

| 16AI-14I-1-316 | 1″ Male I-Line Solid End Cap 316 |

|

| 16AI-14I-1.5-304 | 1 1/2″ Male I-Line Solid End Cap 304 |

|

| 16AI-14I-1.5-316 | 1 1/2″ Male I-Line Solid End Cap 316 |

|

| 16AI-14I-2-304 | 2″ Male I-Line Solid End Cap 304 |

|

| 16AI-14I-2-316 | 2″ Male I-Line Solid End Cap 316 |

|

| 16AI-14I-2.5-304 | 2 1/2″ Male I-Line Solid End Cap 304 |

|

| 16AI-14I-2.5-316 | 2 1/2″ Male I-Line Solid End Cap 316 |

|

| 16AI-14I-3-304 | 3″ Male I-Line Solid End Cap 304 |

|

| 16AI-14I-3-316 | 3″ Male I-Line Solid End Cap 316 |

|

| 16AI-14I-4-304 | 4″ Male I-Line Solid End Cap 304 |

|

| 16AI-14I-4-316 | 4″ Male I-Line Solid End Cap 316 |

|

| 16AI-14I-6-304 | 6″ Male I-Line Solid End Cap 304 |

|

| 16AI-14I-6-316 | 6″ Male I-Line Solid End Cap 316 |

-

I have a header that is capped with 8" I-Line fittings. The water pressure is 60 psi in this tube. I am trying to learn why they would have designed this with the I line and not just a standard Tri-Clamp fitting. Any information would be appreciated.

-

Q I have a header that is capped with 8" I-Line fittings. The water pressure is 60 psi in this tube...... Read moreA A lot of dairy applications utilize I-Line fittings. There is no advantage either way between I-Line vs Tri-Clamp fittings other than the tri-clamp fittings are more readably accessible. Since the tube outside diameters is the same, one option you can take is to remove the current I-Line fitting and weld in place a new tri-clamp ferrule.