Why Sanitary Fittings?

Custom Fabrication Capabilities

Large Selection of Products and Inventory

Same Day Shipping on Most Orders

Exceptional Customer Service

Why Sanitary Fittings?

Custom Fabrication Capabilities

Large Selection of Products and Inventory

Same Day Shipping on Most Orders

Exceptional Customer Service

Shop Popular Categories

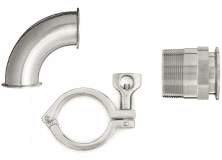

Tri-Clamp Fittings

Our most popular style of process line equipment used within the food, beverage, and pharmaceutical industries.

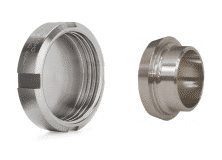

DIN Style Fittings

A European alternative to tri-clamp fittings utilizing metric sizes and popular with select breweries.

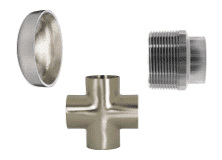

Butt-Weld Fittings

Stainless steel sanitary tube fittings permanently welded into place. Requires on-site welders.

Shop Popular Categories

Tri-Clamp Fittings

Our most popular style of process line equipment used within the food, beverage, and pharmaceutical industries.

DIN Style Fittings

A European alternative to tri-clamp fittings utilizing metric sizes and popular with select breweries.

Butt-Weld Fittings

Stainless steel sanitary tube fittings permanently welded into place. Requires on-site welders.

What Customers Are Saying

Our Full Service Capabilities

We’re the perfect fit for any project. No order minimums, no hassle.

Maintenance

Stainless steel fittings are a popular choice across many industries for their ability to maintain a clean surface that resists corrosion and rust.

Repair

Your parts are covered by our ninety (90) day warranty period from date of shipment under normal use and service.

Overhaul

Your sanitary fittings should last a long time if properly cleaned and maintained. When you need replacement parts, we’ve got you covered.

Our Full Service Capabilities

We’re the perfect fit for any project. No order minimums, no hassle.

Maintenance

Stainless steel fittings are a popular choice across many industries for their ability to maintain a clean surface that resists corrosion and rust.

Repair

Your parts are covered by our ninety (90) day warranty period from date of shipment under normal use and service.

Overhaul

Your sanitary fittings should last a long time if properly cleaned and maintained. When you need replacement parts, we’ve got you covered.

Sanitary Fittings Resources

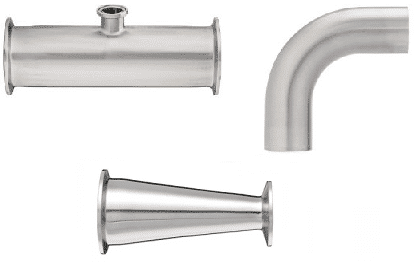

The Ultimate Guide to Tri-Clamp Fittings

The most comprehensive guide to tri-clamp fittings anywhere on the internet. We’re going to break down every component of our most popular style of fittings. Whether you’re new to the industry or an old pro, this guide has something for everyone.

The Ultimate Guide to Bio-Pharmaceutical Fittings

A comprehensive guide to BPE Fittings. We’re going to break down every component of our most specialized style of fittings. Are you new to the Bio-Pharmaceutical industry? This article is for you.

Sanitary Fittings Custom Manufacturing Process

While the majority of items we sell are considered “off the shelf” we also help customers with their custom fabrication needs. Typical items that we usually get requests for include, Tri-Clamp Spool Assemblies, Tri-Clamp Manifolds, Custom bends, and Custom welds for adapters.

Tri-Clamp Gasket Dimensions Guide

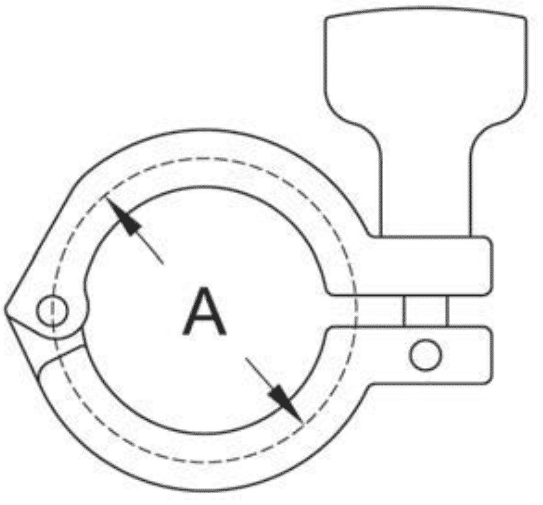

Learn how to properly measure sanitary tri-clamp gaskets for your needs. There are two ways a gasket can be measured. Option one is to measure the outside diameter of the gasket. Option two is to measure the inside diameter.

Sanitary Fittings Dimensions Guide

Learn how to properly measure a sanitary fitting for your needs. There are two ways a sanitary fitting can be measured. Option one is to measure the outside diameter of the tube. Option two is to measure the outside diameter of the flange end. If you choose option two, you should also measure the inside diameter.

Sanitary Fittings Part Number Reference Guide

Compare items for sale from Sanitary Fittings versus the competition. We offer the same quality products for your line process needs with free shipping and same-day delivery.