Tri-Clamp Envelope Gaskets (A40MPGR)

- Available Teflon®/EPDM Core and Teflon®/Viton® Core

- Sizes from 1/2″ up to 8″

- Creates a leak-proof seal between tri-clamp flanges

- Compound Selection Guide

- Temperature & Usage Guide

- Sizing Guide

- FDA / USP Class VI Tested [Learn More]

Sanitary tri-clamp envelope gaskets provide dual materials to make a secure, leak-proof connection between clamp fittings.

An envelope gasket is comprised of a core material (EPDM or Viton) covered by PTFE (Teflon). These gaskets provide the benefits of the core material (elasticity, strength, chemical compatibility) coupled with the characteristics of PTFE.

A variety of materials are available for selection depending upon medium used inline processing. Gaskets range in size from 1/2 inch to 8 inches.

If you would like a copy of a gaskets certificate, please ask for them at the time of order. Certificates are specific per lot of gaskets. Much like a heat number for fittings, gaskets have what is called a lot number. We don’t log these numbers at the time of order but we do include them on the packaging if you need the certificate after receiving them.

Please see Compound Selection Guide for compatibility information.

| Size (Tube OD) |

Material | ||||||

|---|---|---|---|---|---|---|---|

| Teflon®/EPDM Core | Teflon®/Viton Core | ||||||

| 1/2" | 40MPGR-.50-EPDM | 40MPGR-.50-VITON | |||||

| 3/4" | 40MPGR-.75-EPDM | 40MPGR-.75-VITON | |||||

| 1" | 40MPGR-1-EPDM | 40MPGR-1-VITON | |||||

| 1-1/2" | 40MPGR-1.5-EPDM | 40MPGR-1.5-VITON | |||||

| 2" | 40MPGR-2-EPDM | 40MPGR-2-VITON | |||||

| 2-1/2" | 40MPGR-2.5-EPDM | NA | |||||

| 3 " | 40MPGR-3-EPDM | NA | |||||

| 4 " | 40MPGR-4-EPDM | NA | |||||

| 6" | 40MPGR-6-EPDM | NA | |||||

| 8 " | 40MPGR-8-EPDM | NA | |||||

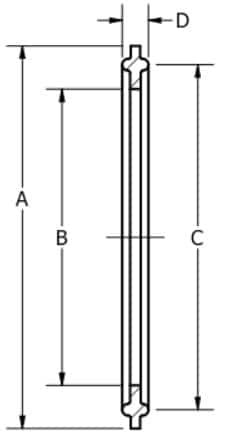

Tri-Clamp Gasket Sizes & Dimensions

| Sanitary Size | A | B | C | D |

| 1/2" | .875 | .4375 | NA | |

| 3/4" | .875 | .6250 | NA | |

| 1" | 1.984" | .900" | 1.718" | 0.203" |

| 1 1/2" | 1.984" | 1.400" | 1.718" | 0.203" |

| 2" | 2.515" | 1.900" | 2.218" | 0.203" |

| 2 1/2" | 3.050" | 2.400" | 2.781" | 0.203" |

| 3" | 3.579" | 2.900" | 3.281" | 0.203" |

| 4" | 4.682" | 3.869" | 4.344" | 0.203" |

| 6" | 6.570" | 5.813" | 6.176" | 0.203" |

| 8" | 8.570" | 7.813" | 8.165" | 0.238" |

| 10" | 10.570" | 9.813" | 10.156" | 0.238" |

| 12" | 12.570" | 11.813" | 12.151" | 0.238" |

Tri-Clamp Gasket Comparison Guide

| Gasket | Temperature Range | Recommended Usage | Not Recommended | Industry | Certification Approval |

|---|---|---|---|---|---|

| Buna (Nitrile) | Standard: -35°F to 250°F (-37°C to 121°C) | Water, Oils, Fuels | Ketones, Strong Acids, Sunlight, Ozone, Weathering | Food & Beverage | FDA Approved |

| EPDM (Ethylene Propylene) | Standard: -65°F to 300°F (-54°C to 149°C) | Sunlight, Weathering, Hot Water, Steam, Select Acids/Bases, Alcohols | Oils, Fuels | Bio-Pharmaceutical, Food & Beverage, Drinking Water | USP Class VI Tested |

| PTFE (Teflon®) | Standard: -100°F to 450°F (-74°C to 232°C) | Chemical, Heat, Pressure Applications | Stretching, Elasticity | Chemical Processing | USP Class VI Tested |

| FKM (Viton®) | Standard: -15°F to 437°F (-26°C to 222°C) | Vacuum, Most Acids / Chemicals, Oils, Fuels | Ketones, Ammonia, Hot Water / Steam | Chemical Processing | USP Class VI Tested |

How to Measure Tri-Clamp Fittings

Tri-Clamp Fittings and Gasket Sizing Guide

| Sanitary Size |

Flange OD (?) |

Tube ID (?) |

Tube OD (?) |

|---|---|---|---|

| 1/2″ | 0.984 | 0.370 | 0.500 |

| 3/4″ | 0.984 | 0.620 | 0.750 |

| 1″ | 1.984 | 0.870 | 1.000 |

| 1 1/2″ | 1.984 | 1.370 | 1.500 |

| 2″ | 2.516 | 1.870 | 2.000 |

| 2 1/2″ | 3.047 | 2.370 | 2.500 |

| 3″ | 3.579 | 2.870 | 3.000 |

| 4″ | 4.682 | 3.834 | 4.000 |

| 6″ | 6.562 | 5.782 | 6.000 |

| 8″ | 8.602 | 7.782 | 8.000 |

| 10″ | 10.570 | 9.782 | 10.000 |

| 12″ | 12.570 | 11.760 | 12.000 |

Looking for even more information on Tri-Clamp fittings?

We have everything you need. Read "The Ultimate Guide to Tri-Clamp Fittings"

Additional information

-

What is the Pressure rating for PTFE envelope EPDM gasket ?

-

Q What is the Pressure rating for PTFE envelope EPDM gasket ?A Gaskets do not have a pressure rating associated with them. The tri-clamps that hold the gaskets and ferrules together do, however. For more information, please see our Tri-Clamp Fittings Burst Pressure and Temperature Ratings Guide.