The Ultimate Guide to Washdown Systems

In the world of industrial sanitation, washdown systems (also known as washdown stations) are of the utmost importance. These systems play a vital role in industrial settings’ cleaning and disinfection processes, laying the groundwork for a secure, hygienic working environment.

In this guide, we take a deep dive into the complexities of washdown systems, highlighting their benefits and providing incisive guidance on selecting and implementing these industrial tools.

CHAPTER 01

Understanding Washdown Systems

CHAPTER 02

The Significance of Washdown Systems in Various Industries

CHAPTER 03

Factors to Consider When Choosing a Washdown System

CHAPTER 04

Implementing Washdown Systems

CHAPTER 05

Maintaining Hygiene Standards with Washdown Systems

CHAPTER 06

Making Your Washdown System Cost-Effective

CHAPTER 07

Why You Should Get a Washdown System

CHAPTER 01

Understanding Washdown Systems

Washdown systems have a number of important components. We’ll cover each part and how it is used in the nsystem.

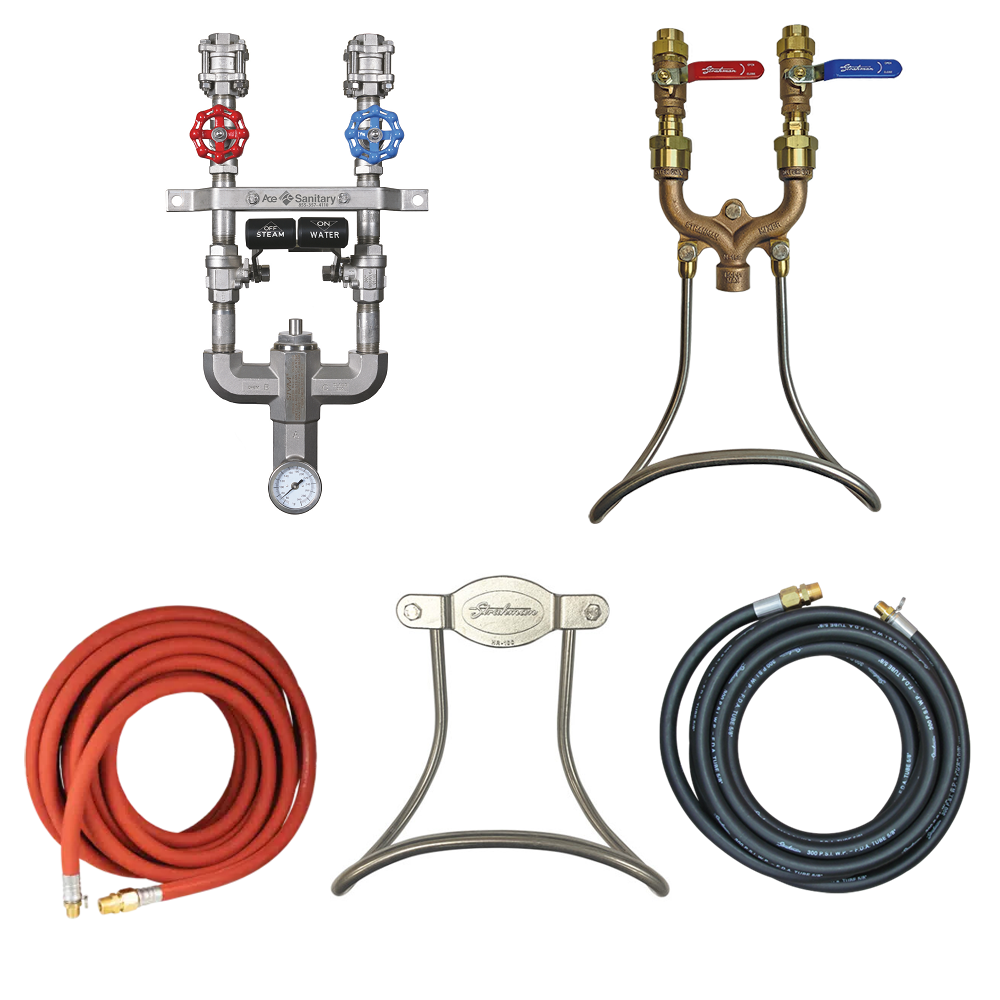

At its core, a washdown system comprises a range of equipment, including hoses, nozzles, and mixing stations, all tailored to guarantee thorough cleaning in industrial facilities. Their primary purpose is to mitigate contamination risks, not only meeting but consistently exceeding hygiene standards.

Each element of a washdown system serves a specific role. Hoses, designed to withstand high pressures and temperatures, transport cleaning fluids to areas needing sanitation. Spray nozzles, affixed at the end of these hoses, control the direction and pressure of cleaning fluids, effectively removing contaminants. Meanwhile, mixing stations facilitate the blending of hot and cold water or steam and cold water to create a cleaning solution at the desired temperature.

Together, these components work together to deliver a powerful and efficient cleaning process.

CHAPTER 02

The Significance of Washdown Systems in Various Industries

There are a number of industries that rely on washdown systems to meet and exceed hygiene standards.

Washdown systems are essential across a wide range of industries. Sectors like food processing and pharmaceuticals rely heavily on these systems to meet stringent hygiene standards. In these industries, the intrusion of foreign substances can have disastrous consequences, making washdown systems imperative.

Breweries and wineries depend on washdown systems to maintain cleanliness and product integrity. Given the risks, a well-designed washdown system can differentiate between a high-quality product and a ruined batch.

In other manufacturing plants, washdown systems safeguard valuable equipment and machinery. By removing contaminants and residues, these systems enable uninterrupted operation, enhancing productivity by minimizing machine downtime due to unexpected cleaning or repairs.

CHAPTER 03

Factors to Consider When Choosing a Washdown System

There are 3 critical factors to take into account when selecting the correct washdown sytem for your needs.

Maximizing cleaning efficiency hinges on selecting the right washdown system. Consider these critical factors when making an informed decision:

- Your Industry: Each industry has unique regulatory requirements and practical needs that inform the choice of an appropriate washdown system. For example, food processing plants require systems that efficiently remove food residues, while pharmaceutical facilities may need systems capable of handling chemical contaminants.

- Facility Size and Layout: The structure and dimensions of your facility significantly influence the type of washdown system required. A large plant may necessitate a system with extended hoses and robust nozzles, whereas a smaller establishment could benefit from a compact, manageable system.

- Type of Contaminants: The nature of contaminants you encounter can greatly affect your choice of washdown system. Stubborn residues might require a system allowing for hot water or steam usage, while easily removable contaminants may only need a cold-water solution.

CHAPTER 04

Implementing Washdown Systems

How you implement washdown systems into your workflow is just as important as which system you chose.

Once you’ve identified the most suitable washdown system, the next step is its effective implementation. This process generally involves two critical steps:

- Installation: Engaging a professional for system installation is crucial to ensure optimal performance and safe usage. Proper setup of all components is guaranteed in this manner.

- Staff Training: Your staff needs to understand how to operate and maintain the washdown system to fully realize its benefits. This includes knowing how to adjust the system for different cleaning needs, conducting routine maintenance, and adhering to safety precautions.

CHAPTER 05

Maintaining Hygiene Standards with Washdown Systems

When you have your washdown sysatem in place, maintaining proper hygiene standards becomes a new focus.

With an appropriate washdown system, achieving elevated hygiene standards becomes feasible. Establishing a regular maintenance routine for the system is the essential first step. This could involve daily inspections for leaks and damage, weekly system cleaning, and periodic professional servicing.

By keeping the system in excellent condition, its cleaning performance can remain optimal, ensuring compliance with industry-specific sanitation regulations and fostering a safe, hygienic work environment.

CHAPTER 06

Making Your Washdown System Cost-Effective

While it may seem like a high price to pay, washdown systems can be incredibly cost-effective.

While the initial cost of a washdown system might seem significant, it’s a cost-effective investment. The benefits it offers in terms of improved hygiene, reduced risk of contaminants, and enhanced operational efficiency decidedly outweigh the initial costs.

Furthermore, with consistent maintenance and staff training, the system’s performance can be further improved, ensuring maximum return on investment.

CHAPTER 07

Why You Should Get a Washdown System

By considering the factors highlighted in this guide, you can choose a system that best aligns with your industry and specific needs.

Whether you are a plant manager, brewery operator, or involved in food processing, understanding and implementing a suitable washdown system is paramount for your operation’s success. An adequate system guarantees your facilities’ cleanliness, safeguards product quality, bolsters productivity, and ensures compliance with hygiene standards.

By considering the factors highlighted in this guide, you can choose a system that best aligns with your industry and specific needs, ensuring cost-effective and exceptional sanitation. Furthermore, with proper maintenance and usage, your washdown system can serve your facility for many years, making it a valuable investment for your business.