One often-overlooked component that plays a significant role in maintaining hygiene and preventing contamination in manufacturing processes is the sanitary hose. Knowing when to replace your sanitary hoses is essential for ensuring product quality, regulatory compliance, overall operational excellence, and can prevent unplanned downtime.

Understanding Your Hose’s Lifespan:

Sanitary hoses are subject to rigorous conditions, handling a variety of substances and enduring frequent cleaning cycles. Over time, wear and tear can compromise their integrity, leading to potential risks such as leaks, contamination, and product recalls. While the lifespan of sanitary hoses can vary based on factors like material, usage, and maintenance practices, a general rule is to replace them every 3 to 5 years, even if they visually appear to be intact.

5 Important Signs of Wear and Tear:

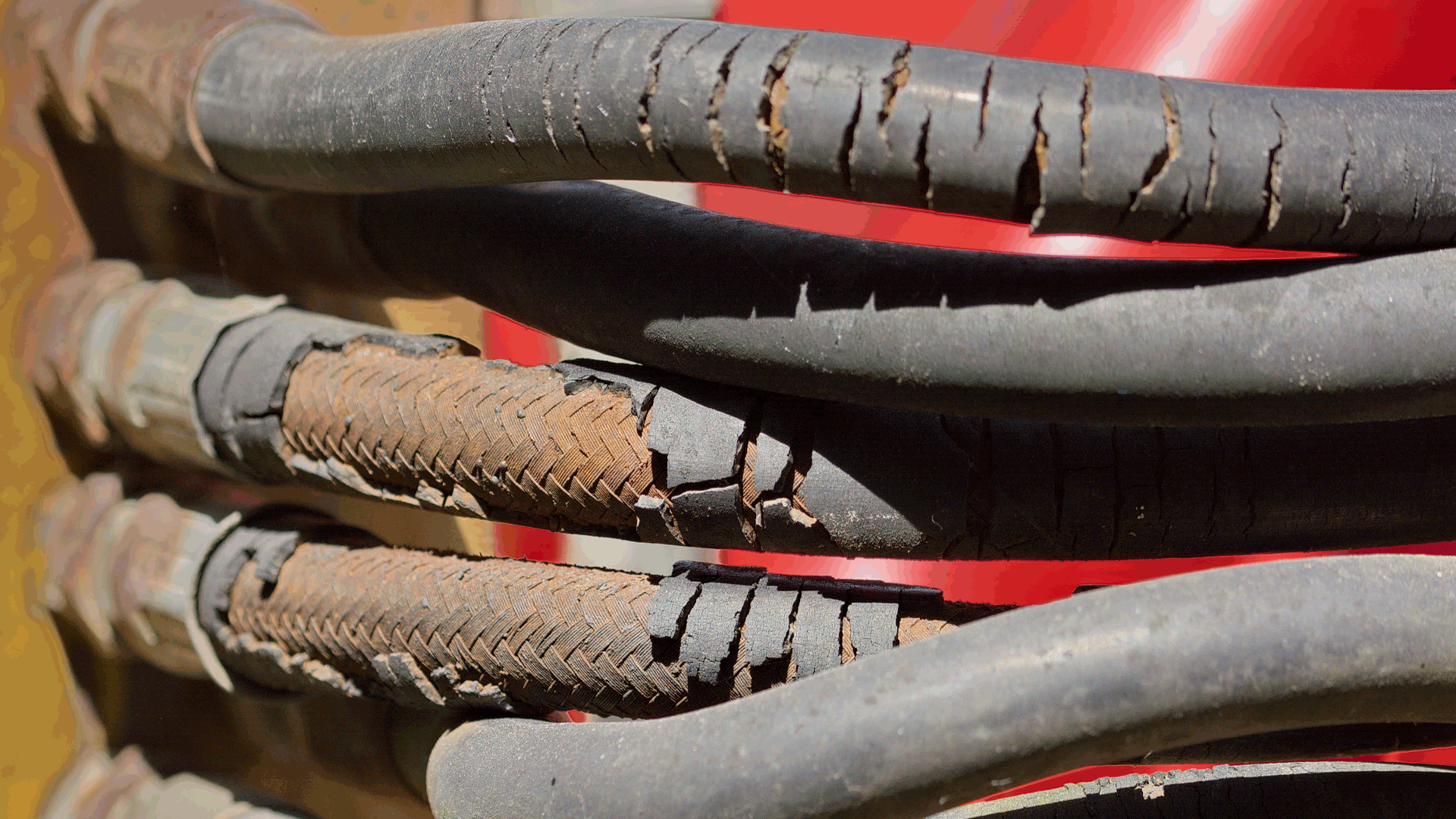

- Cracking and Brittle Texture: Inspect hoses for visible cracks, especially near fittings and bends. Brittle or hardened textures are indicators that the hose material may be degrading, making it susceptible to failure.

- Bulging or Swelling: Swollen or bulging sections may suggest internal damage, compromising the structural integrity of the hose. This can result from exposure to corrosive chemicals or extreme temperatures.

- Discoloration: Changes in the color of the hose material could signify chemical degradation or the presence of contaminants. Regularly check for any unusual discoloration, as it may compromise the quality of the product being conveyed.

- Foul Odors: Unpleasant smells emanating from the hose could indicate bacterial growth or product residue. This not only poses a health risk but also compromises the quality and purity of your end product.

- Leaks and Drips: Visible leaks or drips are obvious signs of hose failure. Regularly inspect hose connections and fittings for any indications of leaks, as these can lead to product loss and contamination.

Be Proactive with Your Maintenance:

- Regular Inspections: Implement a proactive inspection schedule to detect early signs of wear. Visual inspections should be supplemented with periodic pressure tests to ensure the structural integrity of the hoses.

- Proper Cleaning Protocols: Follow recommended cleaning protocols to prevent the buildup of contaminants and residues within the hoses. Proper cleaning not only extends the lifespan of the hoses but also ensures product quality and compliance with industry regulations.

- Documentation and Traceability: Maintain detailed records of hose usage, cleaning, and replacement. This documentation aids in traceability, making it easier to identify potential issues and adhere to regulatory requirements.

The Takeaway:

In the world of industrial manufacturing, the efficiency and reliability of equipment is crucial, and sanitary hoses play a significant role in maintaining product quality and regulatory compliance. Regular inspections, proactive maintenance practices, and adherence to replacement schedules are essential steps in ensuring the longevity and effectiveness of your sanitary hoses. By staying vigilant and proactive, industrial buyers can safeguard their processes, protect their reputation, and contribute to the overall success of their operations.

Sanitary Fittings is excited to offer a large selection of fully customizable hoses. Customize everything from your hose size, length, and end styles. We also continue to offer our off-the-shelf hoses to keep your operation up and running.