The Ultimate Guide to Tri-Clamp Fittings

The most comprehensive guide to tri-clamp fittings anywhere on the internet.

We’re going to break down every component of our most popular style of fittings.

Whether you’re new to the industry or an old pro, this guide has something for everyone.

Let’s do this!

CHAPTER 01

Introduction to Tri-Clamp Fittings

CHAPTER 02

What are Tri-Clamp Fittings?

CHAPTER 03

How do Tri-Clamp Fittings Work?

CHAPTER 04

Cleaning & Maintenance

CHAPTER 05

How are Tri-Clamp Fittings Measured?

CHAPTER 06

Material Selection

Introducing Tri-Clamp Fittings

A lot goes into creating a successful manufacturing process.

However, if your company works in the food, beverage, or biopharmaceutical industries, you face specific requirements that can be especially demanding.

Just one example of the precision equipment utilized by the food, beverage and pharmaceutical industries is tri-clamp fittings. By better understanding what they are, how they work, and the options available, you’ll know which ones to choose for your unique manufacturing processes.

What Are Tri-Clamp Fittings?

Companies in the food, beverage, and biopharmaceutical industries depend on a number of components to transport products during their manufacturing processes.

Items such as unprocessed milk, wort for beer, wine and even medicines need to move from point A to point B during the manufacturing process.

Helping along the way are a variety of sanitary tubes and valves. An essential subset of this processing equipment are tri-clamp fittings.

These fittings make it possible to connect different sections of process lines with varying sizes and end-point connections. For example, let’s say you have an 8-inch line that needs to be reduced to 4-inch. In order to accommodate this transition, you’ll most likely need an 8″ x 4″ Tri-Clamp Concentric Reducer.

This is exactly what tri-clamp fittings do. Once you bring the two other components together, a tri-clamp fitting is used to ensure they stay that way (We’ll get into how those connections are made a little later).

These fittings are extremely versatile, which is one more reason they’ve become so popular. You can use them to make connections between a large variety of endpoints with different types of adapters. Male/Female NPT (National Pipe Thread), end caps, and butt welds are just a few examples. They can also be assembled a number of different ways to support whichever layout configuration your processing plant may need.

The importance of sanitary fittings to the manufacturing process

Tri-clamp fittings are a subcategory of sanitary fittings, which themselves are a subset of normal fittings. The reason normal versions can’t be used in the food, beverage, and biopharmaceutical industries is that stainless steel allows for small pockets and can easily suffer nicks and scratches. These flaws may often be microscopic, but they are still large enough to collect and breed the kinds of impurities that no company wants to worry about becoming a part of their manufacturing processes.

Sanitary fittings don’t carry the same kind of risk as they are polished to an almost flawless finish, reducing the likelihood of these flaws ever developing.

Tri-clamp fittings vs. Tri-clover fittings

Before we go into greater detail about how tri-clamp fittings work, it’s worth addressing how they differ from tri-clover fittings. Fortunately, it’s an easy explanation: they don’t.

Tri-clamp fittings and tri-clover fittings are the same exact thing.

However, the company eventually sold the name and began putting their focus on other products. While the name “tri-clover” was copyrighted, the design of these fittings was not. Soon other companies began manufacturing products in their likeness and the term “tri-clamp” was born.

So, while the name “tri-clover fittings” is still sometimes used throughout the food, beverage, and biopharmaceutical industries, it’s being replaced by the far more common name, “tri-clamp.” While this term was originally used to refer to the Tri-Clover 3-segmented clamps, it’s now used for all tri-clamp fittings across all industries.

Alternative styles of fittings

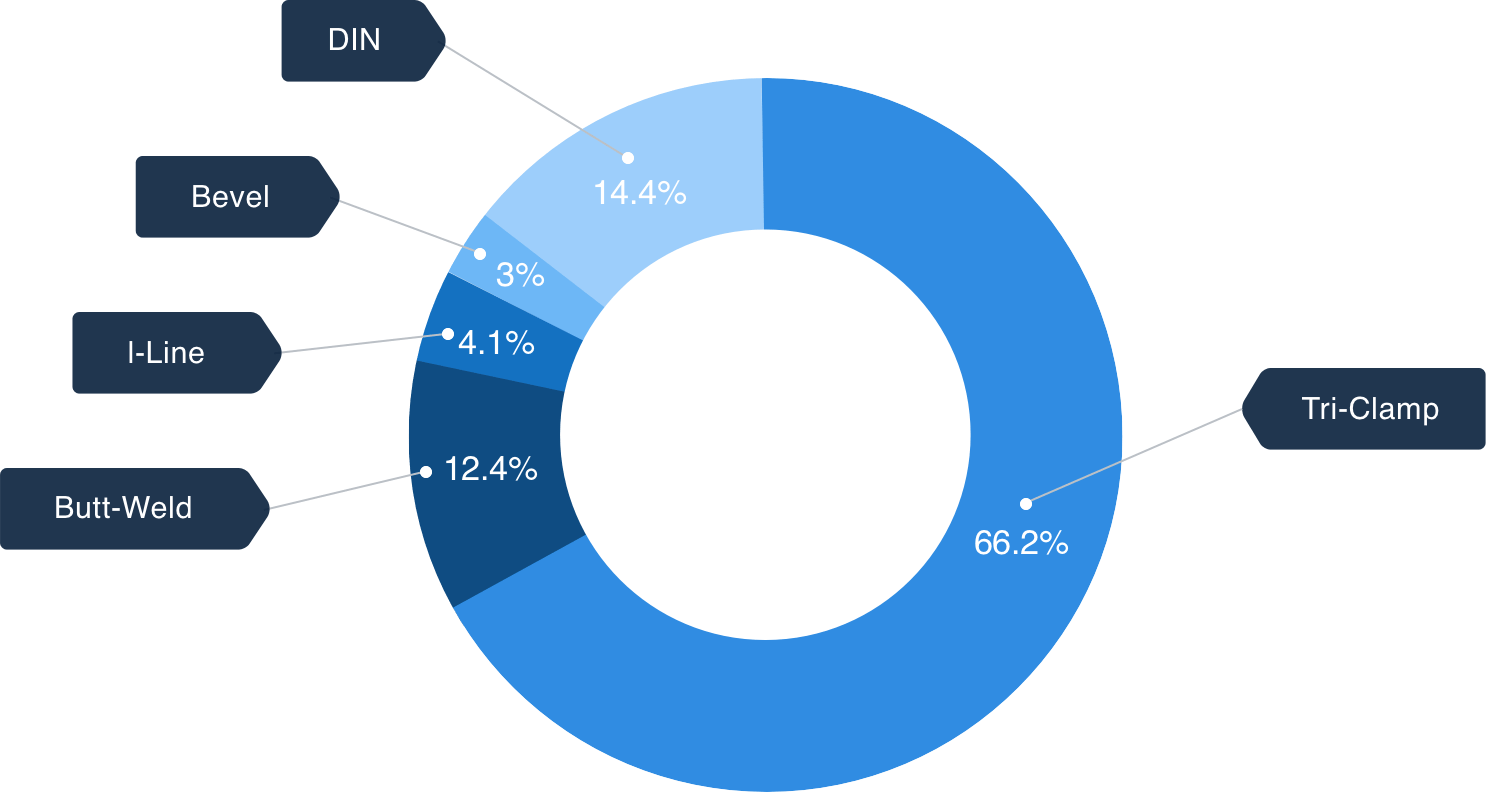

While there are many styles of fittings used within the food & beverage industries, tri-clamp fittings are the most popular. According to Bryan Wells, president of Steel & O’Brien Manufacturing, “67% of fittings sold within the United States are tri-clamp.”

Other choices for styles of fittings include:

I-Line Fittings

Similar to tri-clamp fittings, this style uses an alternative flange-face design.

DIN Fittings

A European alternative to tri-clamp fittings utlizing metric sizes and popular with select breweries.

Butt-Weld Fittings

Stainless steel sanitary tube fittings permanently welded into place. Requires on-site welders.

Bevel Seat Fittings

Much like I-Line fittings, this less popular style employs a nut and gasket to complete the connection

The pie chart below displays the level of popularity among the different styles of fittings that we see from website visitors:

Manufacturing countries

Several countries throughout the world manufacture tri-clamp fittings including the United States as seen in the image above. However, China is the largest producer and exporter of these fittings.

Mike Komassa, National Account Manager at Sanitube, estimates that.

“well over 50% of the fittings used within the United States are manufactured in China”.

Select industries such as biopharmaceutical companies fall under very stringent guidelines for manufacturing. These companies typically install USA-Made parts only in an effort to maintain high-quality standards, product conformity, and traceability in case of manufacturing defects.

3A standards & notation

3-A SSI is an independent, not-for-profit corporation dedicated to advancing hygienic equipment design for the food, beverage, and pharmaceutical industries. They represent the interests of three stakeholder groups with a common commitment to promoting food safety and the public health — regulatory sanitarians, equipment fabricators and processors.

Eric went on to say, “the mission of 3-A SSI is to enhance product safety for consumers of food, beverages, and pharmaceutical products through the development and use of 3-A Sanitary Standards and 3-A Accepted Practices.

All products manufactured and verified in accordance with 3A are etched with the logo you see on the image above. If you’re purchasing tri-clamp fittings without this designation you are taking an unnecessary risk with your processing equipment.

Think of it like this, you wouldn’t take prescription drugs that were not approved by the Food & Drug Administration. Purchasing processing equipment that is not manufactured in accordance with 3A Standards is the same thing.

To learn more about 3A and their mission click here.

How Do Tri-Clamp Fittings Work?

Although we’ve already touched on the function of tri-clamp fittings, it’s important that you understand how they work as, without proper installation and usage a lot can go wrong.

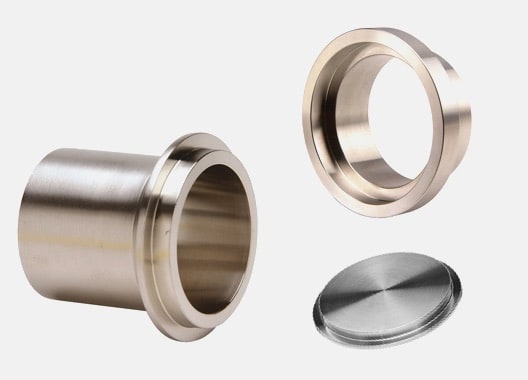

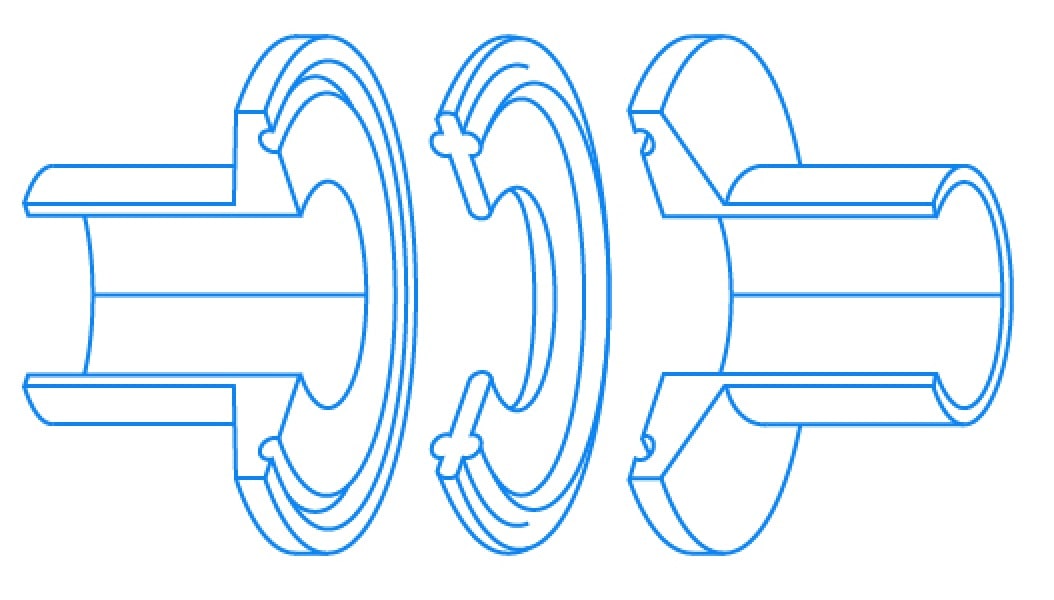

Tri-clamp fittings are made up of two flanged ends (also referred to as ferrules), a gasket, and a clamp to secure the connection.

- Buna

- EPDM

- Teflon

- Viton

To create a secure connection with a tri-clamp fitting, mate the two flanged ends together with a gasket between their two faces. Then, secure the connection in place by using a clamp and then tightening it by hand.

The recommended amount of pressure for tightening wingnuts of tri-clamps is 25 in/lb of torque.

We recommend nothing more than hand tightening clamps for a secure, leak-proof connection. Occasionally, installers will opt for mechanical means to be 100% sure the connection is secure and won’t leak.

This is a big mistake that can result in damaging the fitting, gasket, or both. Overtightening can lead to undue pressure and potential bulging of the gasket, pushing it into the pipeline and creating a foothold where bacteria will build up.

Let the gasket do what it was designed to do and only apply as much pressure as you can by comfortably turning the wingnut with your hand.

Of course, that’s not to say a tight connection isn’t important. When clamps are under-tightened they allow for gaps between the ferrules and the gasket. Even if it doesn’t result in dripping, this kind of gap will be enough to trap materials where clean-in-place (CIP) practices can’t reach. It’s only a matter of time, then, before bacteria begin growing.

CHAPTER 04

Maintaining and Cleaning Your Tri-Clamp Fittings

Another reason to use a tri-clamp fitting in your manufacturing process is that cleaning and maintaining them are so easy.

These fittings are made to be cleaned in place (CIP), but it’s not as though breaking them down for further cleaning is going to require a lot of work, either.

With that being said, how often you actually decide to clean your fittings will depend on the industry you’re in and any laws you need to follow.

For companies that make beer or wine or simply need to regularly run water through their pipes, it may be possible to complete multiple production batches before any cleaning or inspections of the fittings are required.

On the other hand, many companies that make food or pharmaceutical products may need to take apart and inspect their fittings after every single run.

In either case, the simple assembly of tri-clamp fittings makes it easy to take them apart whenever a visual inspection is deemed necessary. If nothing else, it’s helpful to judge the effectiveness of your company’s cleaning practices.

Don’t forget about the gaskets, either. While the two flanged ends and clamp are certainly important, the status of your gasket can’t be overlooked. Check for tears and cracks, as well as stains or debris that don’t come out after a thorough cleaning. The rule of thumb with gaskets is always, “better safe than sorry.” The cost of replacing these components – even if you have to do so regularly – is going to be a lot less than the price of a contaminated process line.

Again, the exact process for cleaning your fittings – and the frequency with which you execute it – may be governed by company policies, industry best practices, and federal or state regulations. However, here are some basic tips for taking care of your tri-clamp fittings and the connection they’re responsible for securing.

- After taking the fitting off for cleaning or maintenance, be sure to inspect the flanged ends, as well, to ensure they are still perfectly aligned. A perfect alignment is critical, but you can’t expect your clamp to pull components or whole pipes into place, so this issue will only get worse until properly addressed.

- Check the gap between the two flanged ends. It should be the same width as your fitting’s gasket to minimize stress placed on the pipes.

- Inspect the surface of the flanged ends, the gasket, and the clamps for any imperfections. Remember, even the most minor of imperfections could lead to costly impurities and leaks.

- Examine the flanged ends for any residue that may interrupt the proper functioning of a new gasket by keeping it from seating properly. If residue does exist, clean it off. Don’t try to scrape it away with something like a screwdriver as that could cause the types of scratches that end up concealing bacteria.

Whenever you do install a new gasket, it’s worth inspecting it beforehand just in case. Obviously, expired or damaged gaskets are never to be used with your tri-clamp fittings. Still, even a brand-new gasket may have a flaw from time-to-time, so it’s worth carefully inspecting it before putting it to use.

If your manufacturing process involves high-pressure steam lines, you’ll want to check your clamps for any changes in torque. Gasket compression can vary because of thermal cycling.

Finally, your processing equipment may have vibrations from pumps and other mechanical devices. For this reason, it’s important to inspect the clamps often to makes sure they are not loosening their grip. We recommend developing a daily, weekly and monthly schedule to inspect all tri-clamp fittings to make sure they are properly installed.

CHAPTER 05

How are Tri-Clamp Fittings Measured?

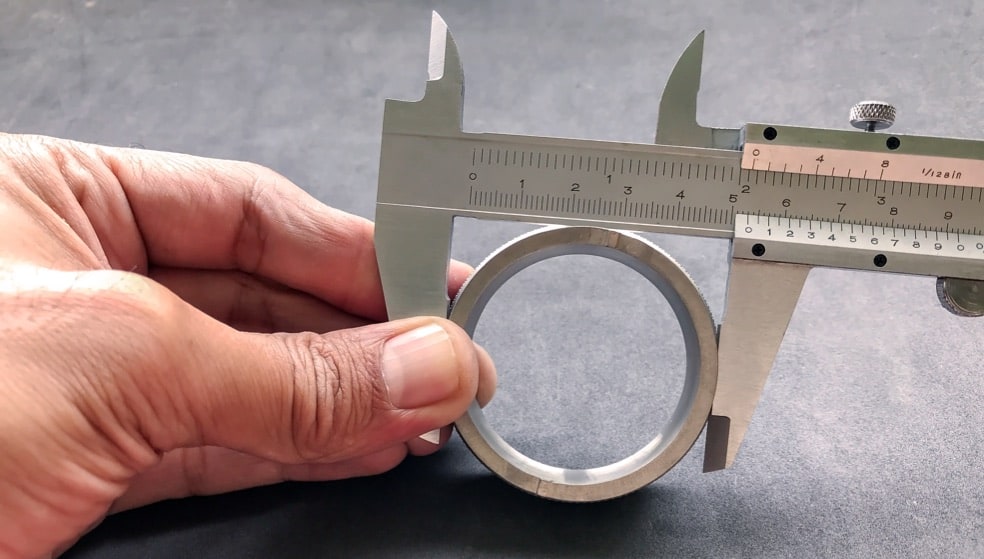

In order for your tri-clamp fittings to work effectively, it is imperative that you know how and where to measure them.

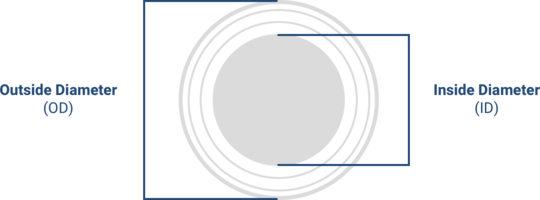

When viewing fittings online you may see a reference to the “Sanitary Size“. This is the size of the fitting as measured by the outside diameter of the tube.

The right size will depend entirely on the size of the tubes you wish to connect. There are two main options for choosing the right tri-clamp fitting size:

- The first option is to measure the outside diameter of the tube end by putting it on a piece of paper and tracing a circle around it. Then, all you need to do is measure the diameter of this circle to determine the measurement you need.

- The second option is to measure the outside diameter of the flange end. Once again, all you need to do is trace a circle around the outside of this end on a piece of paper. Just like before, measure the diameter of this circle.

Next, take this outside diameter (OD) measurement and check it against the measurement table below to find the right sanitary fitting size for your needs.

We also put this video together to show how to properly measure tri-clamp fittings if you need more assistance.

Tri-clamp sanitary fitting sizes

An easy way to check to confirm you’ve made the right choice is by comparing your gasket to your pipe. The inside diameter of a gasket should always be identical to the inside diameter of the pipes so that there’s absolutely no void or intrusion.

The configuration should be perfectly aligned and even all the way around. The smallest irregularity can cause incomplete or inconsistent compression.

| Sanitary Size | OD of Flange End | ID of Tube | OD of Tube |

|---|---|---|---|

| 1/2″ | 0.992 | 0.370 | 0.500 |

| 3/4″ | 0.992 | 0.620 | 0.750 |

| 1″ | 1.984 | 0.870 | 1.000 |

| 1 1/2″ | 1.984 | 1.370 | 1.500 |

| 2″ | 2.516 | 1.870 | 2.000 |

| 2 1/2″ | 3.047 | 2.370 | 2.500 |

| 3″ | 3.579 | 2.870 | 3.000 |

| 4″ | 4.682 | 3.834 | 4.000 |

| 6″ | 6.562 | 5.782 | 6.000 |

| 8″ | 8.602 | 7.782 | 8.000 |

| 10″ | 10.570 | 9.782 | 10.000 |

| 12″ | 12.570 | 11.760 | 12.000 |

The burst pressure and temperature ratings of tri-clamp fittings

Another very common concern about tri-clamp fittings is how they perform in manufacturing environments that involve high temperatures, pressure ratings, or a combination of the two.

Obviously, no amount of choosing the right size, regular cleaning, and proper maintenance will matter of an environment’s conditions are simply too harsh for a fitting to function as designed.

Theoretical Tube Burst Pressure Ratings

| Size (Tube OD) | Dimensions | Burst Pressure (PSI) | |

|---|---|---|---|

| Wall | Gauge | ||

| 3/4″ | 0.065″ | 16 | 8,666 |

| 1″ | 0.065″ | 16 | 9,750 |

| 1 1/2″ | 0.065″ | 16 | 6,503 |

| 2″ | 0.065″ | 16 | 4,875 |

| 2 1/2″ | 0.065″ | 16 | 3,900 |

| 3 | 0.065″ | 16 | 3,248 |

| 4″ | 0.083″ | 14 | 2,730 |

| 6″ | 0.083″ | 14 | 1,820 |

| 6″ | 0.109″ | 12 | 2,543 |

| 8″ | 0.083″ | 14 | 1,365 |

| 8″ | 0.109″ | 12 | 1,907 |

The weakest point of a tri-clamp fitting is where the two flange ferrules connect. This connection point is where a gasket and clamp bring the two fittings together and hold them in place.

If your manufacturing environment creates large amounts of pressure, this is where the clamp is most likely to fail. In environments where temperatures reach extremes, the gasket will be the weakest link in your tri-clamp fitting.

Fortunately, our company offers a number of different options to accommodate just about any manufacturing environment, in terms of temperature and pressure.

Take a look at the two tables below to get a sense for which option will support your needs best.

We have also created a table of theoretical tube burst schedules. Keep in mind that we cannot accurately measure the true burst pressure of a tube fitting without a method for properly sealing them off.

Double Bolt High-Pressure Clamp Ratings

| Size (Tube OD) | Part Number | Service Pressure Rating at 70°F | Service Pressure Rating at 250°F | Dimensions |

|---|---|---|---|---|

| A | ||||

| 1/2 – 3/4″ | 13MHP-050-075 | 1500 | 1200 | 1.062 |

| 1″ – 1-1/2″ | 13MHP-100-150 | 1500 | 1200 | 2.046 |

| 2″ | 13MHP-200 | 1000 | 800 | 2.578 |

| 2-1/2″ | 13MHP-250 | 1000 | 800 | 3.110 |

| 3″ | 13MHP-300 | 1000 | 800 | 3.640 |

| 4″ | 13MHP-400 | 800 | 600 | 4.744 |

| 6″ | 13MHP-600 | 300 | 200 | 6.632 |

Gasket Temperature Ratings

| Gasket | Temperature Range |

|---|---|

| Buna (Nitrile) | Standard: -35°F to 250°F (-37°C to 121°C) |

| EPDM (Ethylene Propylene) | Standard: -65°F to 300°F (-54°C to 149°C) |

| PTFE (Teflon®) | Standard: -250°F to 450°F (-157°C to 232°C) |

| FKM (Viton®) | Standard: -15°F to 437°F (-26°C to 222°C) |

Material Selection for Your Specific Needs

One final and extremely important facet of choosing the right fitting for your needs is the selection of stainless steel alloy. Fittings of almost every style come in both 304 & 316 alloys.

What manufacturers are processing and where will dictate which type of alloy should be selected.

304 Stainless steel is the cheaper option but also susceptible to corrosion and deterioration in certain environments.

316 Stainless Steel is fortified with Molydenum, an element that protects the integrity of the fittings. For more information on the selection between these two alloys, check out the video we created here:

Conclusion

As you now know, tri-clamp fittings may be relatively small compared to the rest of your operation, but they serve an extremely important purpose. The options available are also as diverse as these devices are versatile.

Furthermore, now that you better understand these fittings, you should also feel a lot more comfortable about choosing which ones your manufacturing process requires.

Just one example of the precision equipment businesses like yours must rely on is tri-clamp fittings. By better understanding what they are, how they work, and the options available, you’ll know which ones to choose for your unique manufacturing processes.

Take a look through our inventory and we’re confident you’ll find what you need.

If you do have any questions, please don’t hesitate to contact us phone email. We would be more than happy to further explain any of the above or answer any specific inquiries you have about this important component.