Tri-Clamp Check Valves (45MP)

- Prevent process backflow

- 316L Stainless Steel Alloy

- 32Ra Finish (Roughness Average)

- Suitable for low and medium viscosity fluids

- Maximum operating temperature: 200°F

- Maximum operating pressure: 145 PSI

- View Sizes & Dimensions

Mitigate product media back flow with stainless steel sanitary tri-clamp check valves

Available in 316L Stainless steel alloy. Product is 3A certified for use in all sanitary conditions including food, beverage and pharmaceutical industries.

- Product ships factory direct

- Includes factory 90-Day Limited Warranty

We recommend clamp gaskets and our single-pin heavy duty clamp in order to safely connect this product to the rest of your system.

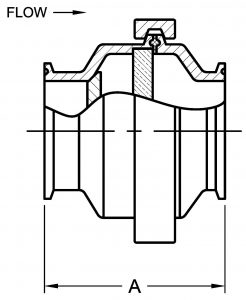

Clamp Check Valve Sizes & Dimensions

Tri-Clamp Check Valve Exploded View

| Size (Tube OD) | Part Number | Dimensions | Cracking Pressure (PSI) | Flow Coefficient (CV) | Line Drawing |

|---|---|---|---|---|---|

| A | |||||

| 1/2" | 45MP-.50-CD-316 | 2.700” | 7.7 | 5 | |

| 3/4" | 45MP-.75-CD-316 | 2.700” | 7.7 | 4 | |

| 1" | 45MP-1-CD-316 | 3.290" | 7.7 | 20 | |

| 1-1/2" | 45MP-1.5-CD-316 | 3.360" | 3.4 | 20 | |

| 2 " | 45MP-2-CD-316 | 3.360" | 1.9 | 40 | |

| 2-1/2" | 45MP-2.5-CD-316 | 3.360" | 0.5 | 60 | |

| 3 " | 45MP-3-CD-316 | 3.360" | 0.5 | 100 | |

| 4 " | 45MP-4-CD-316 | 4.030" | 0.5 | 210 |

How to Measure Tri-Clamp Fittings

Tri-Clamp Fittings and Gasket Sizing Guide

| Sanitary Size |

Flange OD (?) |

Tube ID (?) |

Tube OD (?) |

|---|---|---|---|

| 1/2″ | 0.984 | 0.370 | 0.500 |

| 3/4″ | 0.984 | 0.620 | 0.750 |

| 1″ | 1.984 | 0.870 | 1.000 |

| 1 1/2″ | 1.984 | 1.370 | 1.500 |

| 2″ | 2.516 | 1.870 | 2.000 |

| 2 1/2″ | 3.047 | 2.370 | 2.500 |

| 3″ | 3.579 | 2.870 | 3.000 |

| 4″ | 4.682 | 3.834 | 4.000 |

| 6″ | 6.562 | 5.782 | 6.000 |

| 8″ | 8.602 | 7.782 | 8.000 |

| 10″ | 10.570 | 9.782 | 10.000 |

| 12″ | 12.570 | 11.760 | 12.000 |

Looking for even more information on Tri-Clamp fittings?

We have everything you need. Read "The Ultimate Guide to Tri-Clamp Fittings"

Additional information

Line Drawings

| SKU | Description | Line Drawing |

|---|---|---|

| 45MP-.50-CD-316 | 1/2″ Tri-Clamp Check Valve, 316L |

|

| 45MP-.75-CD-316 | 3/4″ Tri-Clamp Check Valve, 316L |

|

| 45MP-1-CD-316 | 1″ Tri-Clamp Check Valve, 316L |

|

| 45MP-1.5-CD-316 | 1 1/2″ Tri-Clamp Check Valve, 316L |

|

| 45MP-2-CD-316 | 2″ Tri-Clamp Check Valve, 316L |

|

| 45MP-2.5-CD-316 | 2 1/2″ Tri-Clamp Check Valve, 316L |

|

| 45MP-3-CD-316 | 3″ Tri-Clamp Check Valve, 316L |

|

| 45MP-4-CD-316 | 4″ Tri-Clamp Check Valve, 316L |

-

What is the minimum ambient temperature that these valves can operate in? It it possible to use them in -40C ambient temperatures? Also, would there be any issue using these with ethylene glycol/automotive coolant?

-

Q What is the minimum ambient temperature that these valves can operate in? It it possible to use t...... Read moreA The tri-clamp check valve is not meant for fluids below freezing levels. The temperature is roughly from 30°F min. to 225°F max. This valve would not be a good fit this type of application.

Is there an alternative lower cracking pressure for the 2” tri clamp? I see the standard is roughly 2psi

-

Q Is there an alternative lower cracking pressure for the 2” tri clamp? I see the standard is rough...... Read moreA Unfortunately, the cracking pressure of these valves is factory-set and cannot be altered. We are unable to offer alternative cracking pressure valves at this time.

45MP-1.5-CD-316- These are showing out of stock. When could I expect to get these in? Please let me know. Thanks

-

Q 45MP-1.5-CD-316- These are showing out of stock. When could I expect to get these in? Please let ...... Read moreA We actually do have some of these on the shelf at the moment. We'll get a quote over to you as soon as possible.

can you push gas (oxygen) through this? What is minimum pressure requirement?

-

Q can you push gas (oxygen) through this? What is minimum pressure requirement?A It is possible and some customers have used fittings like this in the past. The tri-clamp fittings are leakproof and cracking pressures, dependent upon the size of the valve, are located lower down on this page.

For the 1.5" tri-clamp. What size and type of gasket is used to join the two halves?

-

Q For the 1.5" tri-clamp. What size and type of gasket is used to join the two halves?A Our sanitary fitting sizes are universal. So for the 1 1/2" Tri-Clamp Fittings, you would choose the 1 1/2" Tri-Clamp Gasket size.

What materials are the internals for this Tri-Clamp Check Valve (stopper, o-ring, spring, spider disk)?

-

Q What materials are the internals for this Tri-Clamp Check Valve (stopper, o-ring, spring, spider ...... Read moreA The O-Ring gasket is made of viton. All other components are 316 Stainless Steel.

We need to autoclave this which is 250F, spec says max temp is 200F - can this be made autoclavable?

-

Q We need to autoclave this which is 250F, spec says max temp is 200F - can this be made autoclavable?A

The valve you are looking for would most likely need to be designed for autoclave. The valves we offer are not designed in such a manner. I'm sorry that we cannot be of more assistance for this one.

Can we get a different o-ring than viton? We need compatibility for hydrochloric acid and sodium hydroxide.

-

Q Can we get a different o-ring than viton? We need compatibility for hydrochloric acid and sodium ...... Read moreA We do offer alternative o-rings for the Tri-Clamp Check Valve. Please call us for more information.

Are these check valves suitable for both vertical and horizontal installations?

-

Q Are these check valves suitable for both vertical and horizontal installations?A Yes, these tri-clamp check valves can be used in both vertical and horizontal installations. Please verify cracking pressure along with liquid weight which will impact the opening of check valve.

What is the largest OD of the valve with the clamp used in the center?

-

Q What is the largest OD of the valve with the clamp used in the center?A I'm not sure if I understand your question correctly, but the largest outside diameter tri clamp check valve that we offer is 6". Please call or email for additional information.

What material is the green O-ring gasket in the check valve?

-

Q What material is the green O-ring gasket in the check valve?A The O-Ring gasket in this clamp check valve is made up of Viton. Viton is a brand of synthetic rubber and fluoropolymer elastomer commonly used in O-rings, chemical-resistant gloves, and other molded or extruded goods. Viton fluoroelastomers are categorized under the ASTM D1418 and ISO 1629 designation of FKM.

What is the overall length of this for 2"?

-

Q What is the overall length of this for 2"?A The 2" clamp check valve measures in at 4.583" from head to toe. For other sizes and dimensions please consult our sizing chart found on the product page.