Straight-Line Strainers (KEA0/KEB0)

- Straight-Line Strainer, 316 Alloy

- 3A Approved Design

- Non-permanent connection for easy cleaning

- Design minimizes pressure drop

- We also offer disposable fine particulate filters

Remove particulates from sanitary process lines with the straight-line strainer.

Available in 316L stainless steel alloy. Tri-clamp connections allow for easy access for cleaning and maintenance. If purchasing separate strainer elements, these items are interchangeable.

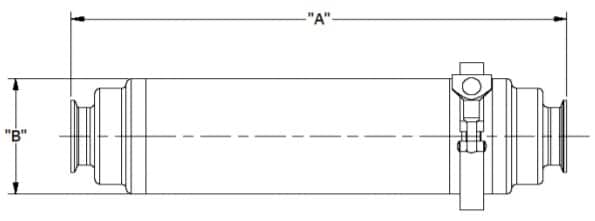

| SIZE | PART NUMBER | A (inches) | B (inches) | Effective Filtration Area ft² | |||

| SHORT | LONG | SHORT | LONG | SHORT | LONG | ||

| 1" | KEA01000 | N/A | 15.8 | N/A | 4 | 0.65 | N/A |

| 1 1/2" | KEA01500 | KEB01500 | 15.8 | 35.4 | 4 | 0.65 | 1.95 |

| 2" | KEA02000 | KEB02000 | 15.8 | 35.4 | 4 | 0.65 | 1.95 |

| 2 1/2" | KEA02500 | KEB02500 | 15.8 | 35.4 | 4.5 | 0.75 | 2.25 |

| 3" | KEA03000 | KEB03000 | 15.8 | 35.4 | 4.5 | 0.75 | 2.25 |

| SPECS | |

| Short Inline Stainer | |

| Long Inline Strainer | |

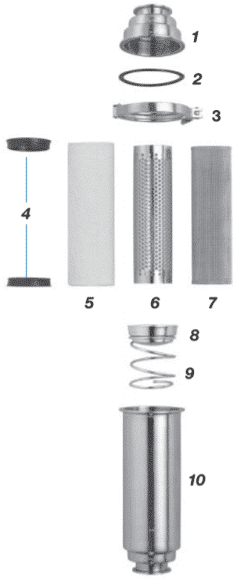

Strainer Components

| ITEM COMPONENT | COMPONENT | MATERIAL |

| 1 | Outlet Assembly | 316SS |

| 2 | Gasket | Buna |

| 3 | Clamp | 304SS |

| 4 | Retaining Rings (filters only) | |

| 5 | Filter Media | Varies |

| 6 | Backup Tube | 316SS |

| 7 | Overscreen (Strainers Only) | 316SS |

| 8 | Distributor Cap | 316SS |

| 9 | Spring | 316SS |

| 10 | Body | 316SS |

| 11 | End Cap | 316SS |

| 12 | Distributor Cap, Handle | 316SS |

Additional information

Line Drawings

| SKU | Description | Line Drawing |

|---|---|---|

| KEB01018-316-A | 1″ Tri-Clamp Inline Strainer, 1/8″ Perf., 35.375″ OAL, 316L | |

| KEB01000-316-A | 1″ Tri-Clamp Inline Strainer, 1/4″ Perf., 35.375″ OAL, 316L | Request Line Drawing |

| KEA01000-316 | 1″ Tri Clamp Inline Strainer, 1/4″ Perf., 15.75″ OAL, 316L | |

| KEA01018-316 | 1″ Tri Clamp Inline Strainer, 1/8″ Perf., 15.75″ OAL, 316L | Request Line Drawing |

| KEB01500-316 | 1 1/2″ Tri Clamp Inline Strainer, 1/4″ Perf., 35.375″ OAL, 316L | Request Line Drawing |

| KEA03000-316 | 3″ Tri Clamp Inline Strainer, 1/4″ Perf., 15.75″ OAL, 316L | Request Line Drawing |

| KEA03018-316 | 3″ Tri Clamp Inline Strainer, 1/8″ Perf., 15.75″ OAL, 316L | Request Line Drawing |

| KEB03000-316 | 3″ Tri Clamp Inline Strainer, 1/4″ Perf., 35.375″ OAL, 316L | |

| KEB03018-316 | 3″ Tri Clamp Inline Strainer, 1/8″ Perf., 35.375″ OAL, 316L | Request Line Drawing |

| KEA02500-316 | 2 1/2″ Tri Clamp Inline Strainer, 1/4″ Perf., 15.75″ OAL, 316L | Request Line Drawing |

| KEA02518-316 | 2 1/2″ Tri Clamp Inline Strainer, 1/8″ Perf., 15.75″ OAL, 316L | Request Line Drawing |

| KEB02500-316 | 2 1/2″ Tri Clamp Inline Strainer, 1/4″ Perf., 35.375″ OAL, 316L | Request Line Drawing |

| KEB02518-316 | 2 1/2″ Tri Clamp Inline Strainer, 1/8″ Perf., 35.375″ OAL, 316L | Request Line Drawing |

| KEB02000-316 | 2″ Tri Clamp Inline Strainer, 1/4″ Perf., 35.375″ OAL, 316L | Request Line Drawing |

| KEB02018-316 | 2″ Tri-Clamp Inline Strainer, 1/8″ Perf., 35.375″ OAL, 316L | Request Line Drawing |

| KEA02000-316 | 2″ Tri Clamp Inline Strainer, 1/4″ Perf., 15.75″ OAL, 316L | Request Line Drawing |

| KEA01500-316 | 1 1/2″ Tri Clamp Inline Strainer, 1/4″ Perf., 15.75″ OAL, 316L | Request Line Drawing |

| KEA02018-316 | 2″ Tri Clamp Inline Strainer, 1/8″ Perf., 15.75″ OAL, 316L | |

| KEA01518-316 | 1 1/2″ Tri Clamp Inline Strainer, 1/8″ Perf., 15.75″ OAL, 316L | |

| KEB01518-316 | 1 1/2″ Tri Clamp Inline Strainer, 1/8″ Perf., 35.375″ OAL, 316L | Request Line Drawing |

-

What is the maximum pressure this can handle?

-

Q What is the maximum pressure this can handle?A

Pressure ratings depend upon temperature, tube size and clamp selection. Please see our Temperature Pressure Guide for additional information.

What material is the #2 gasket in the breakdown chart? Can this be substituted for another material?

-

Q What material is the #2 gasket in the breakdown chart? Can this be substituted for another material?A

It’s a 4” tri-clamp gasket. It can come in any elastomer and the default material is Buna. If you need an alternative we recommend EPDM or Viton. Teflon gaskets are not recommended as a good substitute for this strainer.

WHAT SIZE SIZE MESH OVERSCREENS DO YOU SUPPLY?

-

Q WHAT SIZE SIZE MESH OVERSCREENS DO YOU SUPPLY?A

We offer lengths of 10 3/4" and 30 3/4" overlay screens. More details can be found here.

Does this type of strainer require down time for repair or maintenance?

-

Q Does this type of strainer require down time for repair or maintenance?A Yes, the straight-line strainer requires disassembly of the line in order to clean or make any replacement of existing parts. If you are looking to minimize down time we recommend our Angle-line strainers which can be serviced while maintain process line up time.