Pump Efficiency: 6 Common Questions Answered

Pumps are a critical piece in industrial processes involving liquids. They come in different configurations capable of displacing anything from a few trickles to tens of thousands of gallons a minute.

In some industries, pumps tend to be one of the biggest energy consumers. So, naturally, operators want to maximize energy efficiency to get the biggest bangs for their bucks.

A pump efficiency improvement, no matter how small, can have far-reaching implications on your bottom line over an extended period.

For instance, an organization that uses a 2,500 HP pump that consumes about 2,000 kW of power can see a full day’s running cost several thousand dollars in energy.

In this instance, even single-digit net improvement in pump efficiency can reduce long-term pumping costs by tens of thousands of dollars.

Today, we take a closer look into pump efficiency through these common questions and their answers to help determine:

- How to work out your pump’s efficiency

- Different factors that affect pump efficiency

- The relationship between performance and efficiency

1 – What Is Pump Efficiency?

The efficiency of a machine refers to its ability to convert one form of energy to another effectively. If one unit of energy is supplied to a machine and its output, measured in the same units, is a one-half unit, then the machine’s efficiency is 50%.

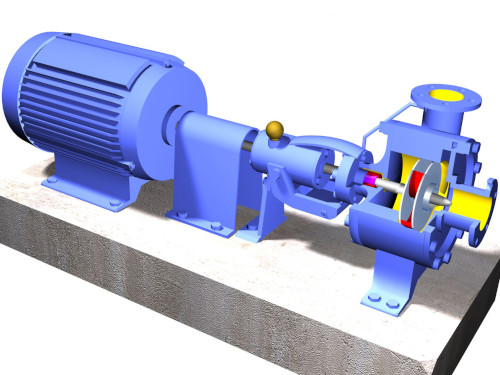

With pumps, the same principle applies, where pump efficiency refers to the ratio of power input to output; that is, the mechanical power input at the pump shaft compared to the hydraulic power of the liquid output.

For instance, the efficiency of a centrifugal pump can be determined by the ratio of water output power to the pump’s shaft input power, as illustrated by the following equation:

Ef = PW / PS

Where:

- Ef = Efficiency

- PW = Water power

- PS = Shaft power

2 – What Are the Individual Efficiencies That Affect Pump Operations?

There are three efficiencies that impact your pump’s operation:

- Hydraulic efficiency: This includes liquid friction and other losses in the volute and impeller. The shape and spacing of the impeller vanes in your pump impact your overall pump efficiency.Impellers with thin profiles (where the shrouds and vanes are close together) usually have low specific speed. Conversely, impellers with broad profiles (shrouds and vanes further apart) have high specific speed.Theoretically, the ideal impeller would have an infinite number of vanes. However, real-world application limits them to between 5 and 7 for clear water pumps and even fewer for more viscous fluids.

- Volumetric efficiency: This represents the energy lost due to leakage in the wear rings, balancing holes in the rear shroud, vane clearances of semi-open impellers, and the balancing holes in the rear cover.Note: Impeller and volute determine volumetric efficiency.

- Mechanical efficiency: Mechanical losses are another key factor in determining pump efficiency. In frame-mounted pumps, mechanical losses are caused by leaks in the mechanical seals, stuffing box, and shaft bearings.In close-coupled pumps, bearing losses are typically figured into the motor efficiency.Note: Combined efficiency or overall pump efficiency is a combination of the above-mentioned individual efficiencies.

See Also: 6 Essential Sanitary Fittings You Need to Know About

3 – Does the Shape of the Performance Curve Predict Efficiency?

Yes. The performance curve and pump efficiency are very much interlinked.

A typical performance curve is somewhat flat at lower specific speeds and deviates further at higher specific speeds.

As such, we observe pump efficiency being lowest with low specific speeds and highest at high specific speeds.

What is specific speed?

Specific speed is a dimensionless rating used in centrifugal pump performance. Despite the name, it’s not actually a speed, although it depends on shaft speed and is a function of the flow rate and differential heat at the pump’s Best Efficiency Point (BEP).

Put simply, specific speed is an index number that can help you predict particular characteristics of a pump. As such, it plays a critical role when selecting the right pump for specific applications and predicting premature failure.

Expert Tip: Efficiency starts to drop when specific speed values dip below peak. But this drop is smaller compared to the drop at a low specific speed value.

4 – What Is a Good Pump Efficiency Rating?

Good pump efficiency is dictated by the type of pump and its size.

Large high-quality pumps that are well-maintained are typically more efficient with ratings of up to 90% or higher. On the other hand, smaller pumps tend to have less efficiency, typically between 50% and 70%.

As a rule, if you take good care of your pumps, you’ll achieve higher pump efficiency.

Another key factor that will influence your pump efficiency is motor efficiency, which depends on the fuel or energy source you use. For pumps, this is usually a choice between electric-powered motors and internal combustion motors.

Electric motors can achieve pump efficiencies of up to 95% or more. Compared to this, internal combustion motors are much less efficient with ratings of less than 40%.

5 – How Do You Maintain Pump Efficiency?

There are four key ways to maintain your pump’s efficiency:

1. Continuous Monitoring

The easiest way to improve pump efficiency is to monitor your pump for any signs of inefficiency. Continuous monitoring makes it easier to notice any efficiency drops and take corrective steps.

For instance, if you monitor flow rate and output power along with the energy consumption, you’ll notice any efficiency loss as soon as it occurs and be able to take action.

2. Regular Care and Maintenance

Another critical way to improve your pump efficiency is to keep your pumps well-maintained. Loss in efficiency is often a result of mechanical defects in your pumps, such as:

- Component failures

- Leakages

- Friction

You can mitigate these issues through proper care and maintenance, which will reveal impending failures. You can achieve this through regular inspections for:

- The level and condition of oil

- Leaks in the seals, pipes, and stuffing box

- The correct discharge pressure

- Vibrations and bearing temperatures

- Unusual noise from the pump

3. Regular Lubrication

Monitor your pump’s lube tanks or sumps, and always have lubricant on hand. You can also track your pump’s lubricant consumption for any significant changes. For instance, if lubricant usage increases, it may signify increased friction in the system.

4. Ensure Proper Pipe Sizes

This is the first and most critical step in any pumping operation. If your pump and piping system don’t match, no amount of monitoring, maintenance, or lubrication will salvage the situation.

Pipes have physical limits to how much fluid they can carry at a specific pressure. If you don’t use the right size of pipes, your pump will lose efficiency.

See Also: How to Clean a Food Grade Hose

6 – Why Does Pump Efficiency Matter?

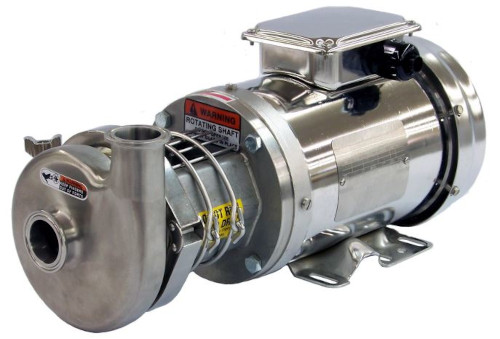

TOP-FLO® Model TF-C Series centrifugal pump

The power used up by your pump as it runs is proportional to the head and output flow it produces. If you want to increase the head or flow, you also need to increase the power to your pump.

On the other hand, the power consumed by your pump is inversely proportional to pump efficiency. To increase efficiency, you must reduce your pump’s power requirement while achieving the same flow/head.

This relationship between power, performance, and efficiency describes why pump efficiency matters. Pump efficiency plays a vital role in your daily pump operation and the overall life and working of your pump.

Ensuring the best pump efficiency will extend your pump’s life while reducing maintenance and operational costs.

Discover Sanitary Fittings—Your Ultimate Pump Solutions Partner

Sanitary Fittings is a customer service company dedicated to providing stainless tube fittings and pump solutions to the food, beverage and pharmaceutical industries.

We do this through partnerships with accredited manufacturers and associations. One such partnership is with TOP-FLO®, a proven name in the sanitary process equipment industry with a reputation built on quality and durability.

Sanitary Fittings stocks TOP-FLO® pumps designed for high-efficiency transfer of products over a wide range of head and viscosity conditions.

The pumps are ideal for various small and medium-sized applications across different industries and are also suitable for CIP (clean-in-place) installations.

Beyond this, Sanitary Fittings is also dedicated to providing the best customer experience.

We have unrivaled customer service and a host of valuable information through our blog. This helps educate our customers making them feel more confident about doing business with Sanitary Fittings.

But don’t take it from us. Here’s what a few happy customers had to say:

“My experience with Sanitary Fittings was perfect. They had the fitting I needed for a competitive price. Shipping was expeditious, and the products were well packed and protected…”

“Sanitary Fittings were quick to respond to my request, kept me informed on all my shipping options and got the periodic to me very quickly.”

“Extremely responsive—they get back to you almost immediately. I would recommend Sanitary Fittings any day.”

Visit Sanitary Fittings for all your pump-related queries and best deals on pumps and parts.

TF-C114 Centrifugal Pump |

Centrifugal Pump Seal Repair Kit 3 |

TF-C100 Centrifugal Pump |

Share on LinkedIn: