When precision matters—especially in food, beverage, and pharmaceutical processes—ensuring accurate and reliable temperature measurements is critical. In these industries, maintaining strict hygienic conditions while still being able to monitor temperature effectively can be challenging. That’s where thermowells come into play. We offer two thermowell product styles—sanitary tri-clamp thermowells and flanged thermowells—that will help you achieve safe, efficient, and precise temperature measurement in your process lines.

What Is a Thermowell?

A thermowell is a protective casing installed in process systems to house a temperature sensing device—such as a thermometer, temperature gauge, or thermocouple. It shields the instrument from direct contact with potentially corrosive or pressurized process media, ensuring both the sensor’s longevity and the system’s integrity. By serving as a barrier, thermowells allow you to remove or replace temperature instruments without having to shut down or drain the process line, saving time and reducing production downtime.

Where Are Thermowells Used?

Thermowells find widespread applications across multiple industries, including:

- Food and Beverage: For pasteurization, cooking, fermentation, and brewing processes where sanitary conditions are paramount.

- Pharmaceutical and Biotechnology: For strict hygiene and contamination control during mixing and batching.

- Dairy: For milk pasteurization and other dairy product processing.

- Chemical and Petrochemical: For corrosion resistance and high-pressure tolerance.

Their robust construction and adaptability make them indispensable in processes requiring highly accurate temperature control, especially in environments where hygiene and safety can’t be compromised.

Sanitary Thermowells for Food Process Lines

When it comes to food-grade or pharmaceutical operations, sanitary thermowells are designed to comply with 3-A sanitary standards. They come with polished surfaces and crevice-free designs to minimize the risk of bacterial growth. These thermowells are typically made from stainless steel or other FDA-compliant materials to ensure they meet strict regulatory requirements.

Standard vs. Lagging Thermowells

- Standard Thermowells: This design places the thermowell directly in contact with the process media. Standard thermowells are ideal for straightforward applications where there’s minimal need for insulation or additional length to pass through external layers.

- Lagging Thermowells: If you have added insulation layers or jacketed vessels, you might need a lagging thermowell. These include an extended shank length to bridge the gap between the outer surface of the insulation and the process medium, ensuring accurate temperature sensing despite the extra material or space.

More information on understanding the differences between standard and lagging thermowells.

Flanged Thermowells and Their Shank Styles

For more heavy-duty applications or those requiring secure flange connections, flanged thermowells are an excellent option. They are bolted or welded directly onto a flange, creating a strong seal that is particularly beneficial in high-pressure or high-temperature environments.

Within flanged thermowells, there are three main shank styles:

- Straight Shank

Uniform diameter throughout the length of the shank.

Best for lower flow and lower velocity applications. - Stepped Shank

The diameter decreases along the length, making it more resistant to flow-induced stress.

Often used to balance strength with responsiveness to temperature changes. - Tapered Shank

Gradual reduction in diameter from the flange to the tip.

Optimized for high-flow or high-pressure applications where reduced drag and increased strength are needed.

Read our Guide to Flanged Thermowell Shank Styles – Straight, Stepped, and Tapered.

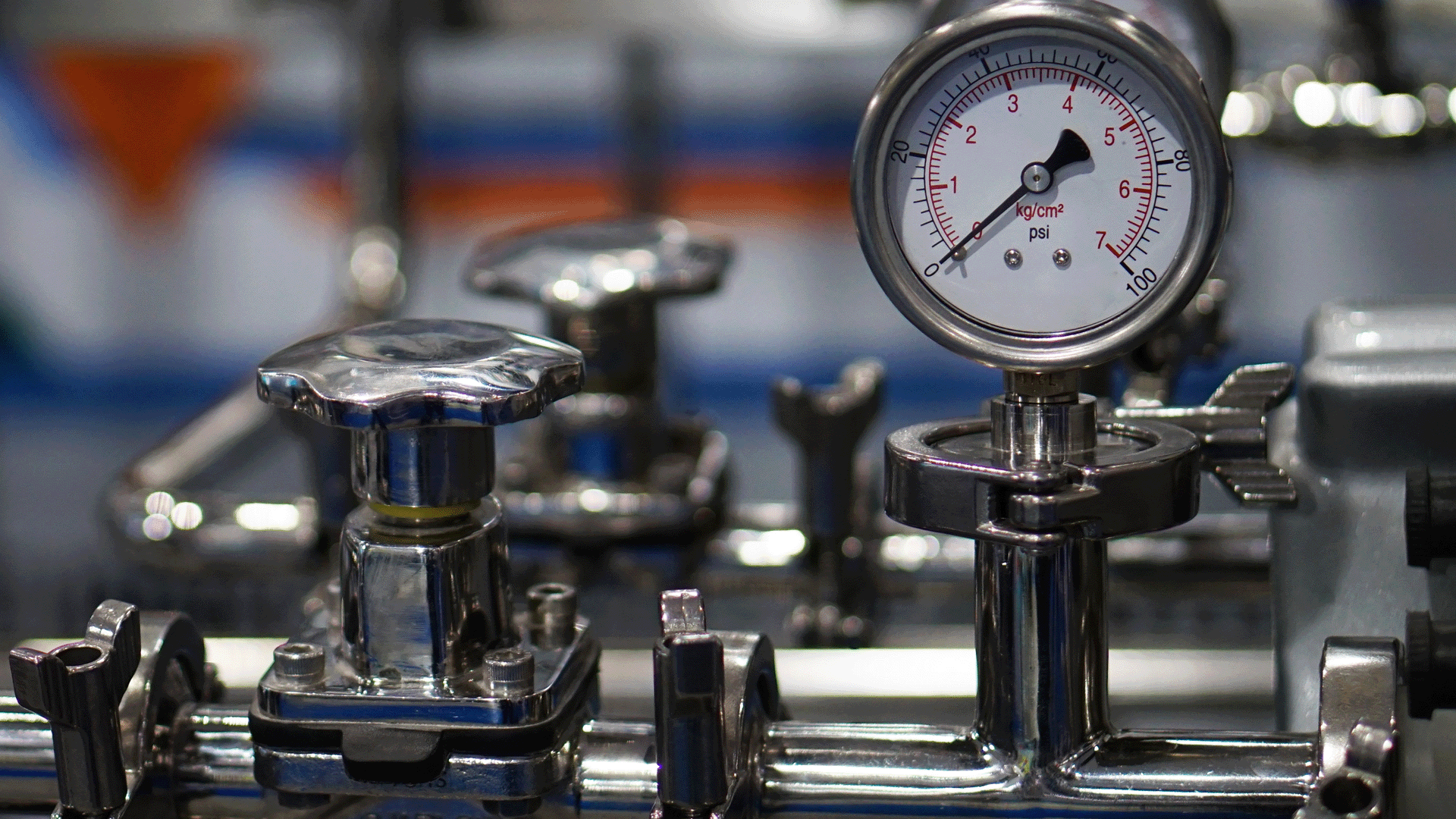

Pairing Thermowells with Temperature Gauges

Choosing the right thermowell is only half the battle—you also need a reliable temperature gauge to complete your setup. We offer a wide range of Reotemp temperature gauges that seamlessly integrate with our thermowell offerings. We’ve listed the most popular styles below:

Reotemp® Sanitary Thermometer with 3″ Dial with Back Connection: These gauges are offered in a variety of stem lengths, process connection types, and temperature ranges.

Reotemp® Sanitary Thermometer with 3″ Dial with Bottom Connected: Similar to a back connected gauge, these high-quality gauges also offer a wide-range of customizable options.

Whether you need a tri-clamp or NPT gauge, you can trust our product line to interface smoothly with both sanitary and flanged thermowells. Our team can help you choose the right combination based on your process requirements—taking into account temperature range, pressure ratings, and material compatibility.

Conclusion

Thermowells are an essential tool for protecting and extending the life of your temperature instruments while maintaining process integrity—especially in sanitary applications where hygiene and safety take top priority. Whether you need a standard or lagging thermowell design, or prefer a straight, stepped, or tapered shank in a flanged configuration, we have you covered. And with our comprehensive range of temperature gauges designed to work seamlessly with these thermowells, you can confidently equip your food, beverage, pharmaceutical, or dairy process line with accurate and reliable temperature measurement solutions.

Ready to find the perfect thermowell and temperature gauge solution for your operation? Contact us today to learn more about our new product offerings and how we can help your process run more efficiently and hygienically.