Choosing the right valve for your food, beverage, or biopharmaceutical facility is crucial for maintaining product quality, operational efficiency, and regulatory compliance. Among the most commonly used valves in these industries are ball valves and butterfly valves. While both styles can handle a wide variety of applications, they each have unique advantages and drawbacks that will guide your selection. Below, we break down the main differences, typical industry uses, and key considerations to help you choose the right solution for your facility.

Ball Valves: Precision Control and Robust Construction

1. Design and Operation

A ball valve features a spherical disk (the “ball”) with a hole through the center. When the handle is turned, the hole aligns with the flow path to allow fluid to pass, or it turns perpendicular to block the flow entirely. This quarter-turn mechanism offers quick and easy on/off control.

2. Common Industries

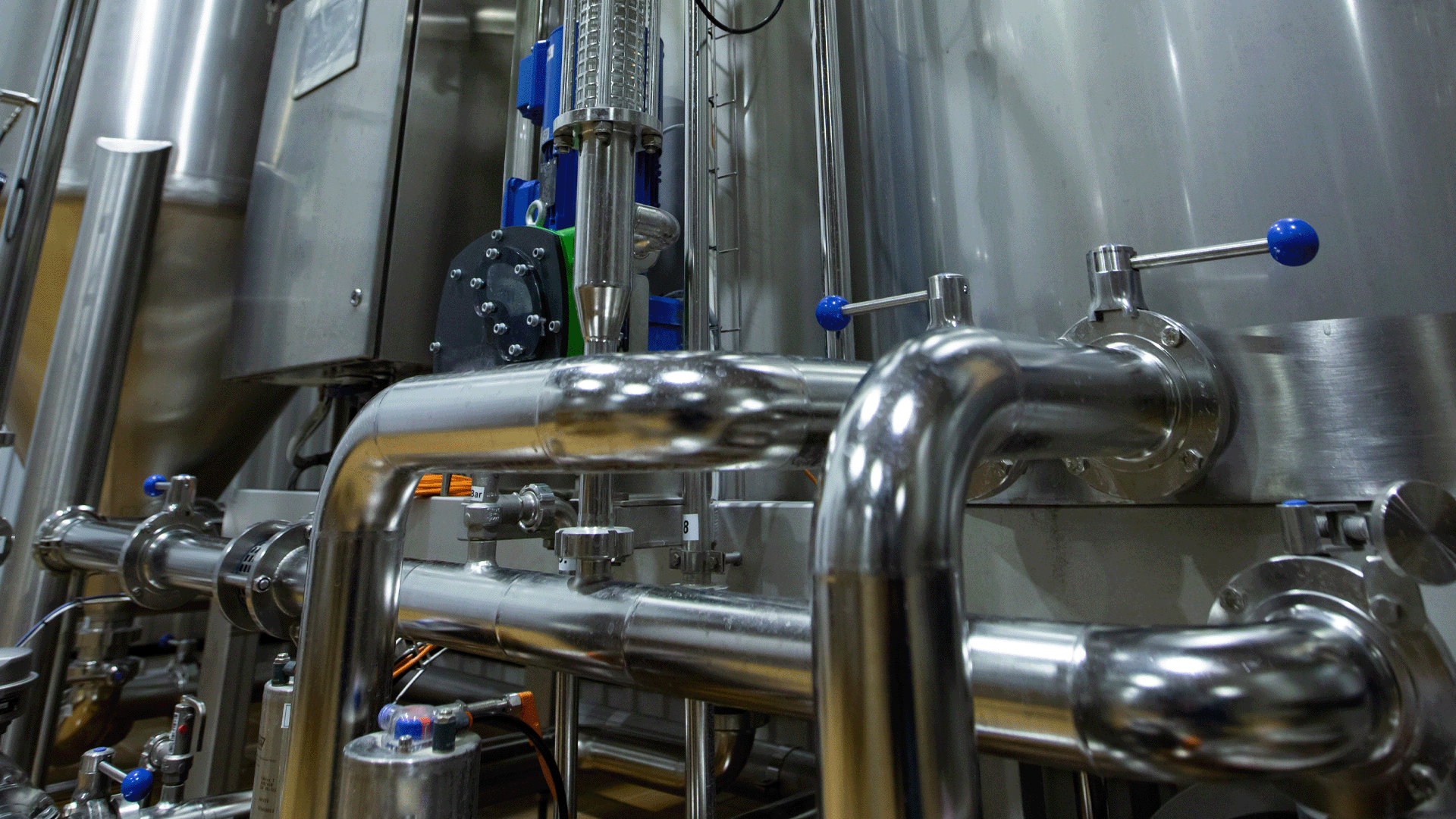

Ball valves are used across many sectors, including food and beverage, dairy, brewery, and biopharmaceutical operations. Their ability to handle higher pressures and provide a secure, leak-resistant seal makes them indispensable for applications where minimal contamination and precise shut-off are paramount.

3. Benefits

- Excellent flow control: Ball valves create very little flow restriction, reducing pressure drops.

- Reliable sealing: The tight seal of a ball valve helps mitigate any risk of product loss or contamination.

- Durability: Their robust construction allows them to handle higher pressure applications.

- Versatile connection options: Available in tri-clamp, flanged, and NPT configurations, among others.

4. Drawbacks

- Cost: Ball valves can be more expensive than butterfly valves, particularly for large diameters or specialty materials.

- More complex design: The internal ball mechanism can be more prone to sediment build-up in certain applications, though proper maintenance can address this issue.

Butterfly Valves: Lightweight and Economical Flow Regulation

1. Design and Operation

A butterfly valve employs a circular disk positioned in the center of the pipe, which rotates on a shaft to regulate the flow. This quarter-turn valve is lighter and more compact than most ball valves, providing quick shut-off and effective flow regulation.

2. Common Industries

Butterfly valves are a staple in many low- to medium-pressure systems, especially within the food and beverage sector (e.g., juice, water, or light dairy operations). They are also widely used in pharmaceutical and chemical processing where frequent cleaning and sterilization are required.

3. Benefits

- Economical: Typically less costly than ball valves, especially in larger sizes.

- Compact design: Their slim profile makes them ideal for tight spaces where weight and room are concerns.

- Easy installation: Butterfly valves often come with clamp or flanged ends, facilitating simpler setup and maintenance.

- Good for throttling: While best for on/off control, they can also provide a basic level of flow regulation.

4. Drawbacks

- Sealing capabilities: Although modern butterfly valves are highly reliable, they may not achieve the same zero-leak performance of a ball valve in high-pressure environments.

- Pressure drop: Because the disk remains in the flow path, there is a greater pressure drop compared to a ball valve in a fully open position.

Which Valve Is Right for Your Facility?

For High-Pressure, Precise Shut-Off

If you require a strong, leak-proof seal under high pressure or for critical processes—such as in certain biopharmaceutical applications—ball valves may be the better choice. Their robust construction and superior sealing capabilities often justify the higher initial cost.

For General Flow Control and Cost Efficiency

If your process operates under moderate pressures and you need a lightweight, economical option, consider a butterfly valve. It performs well in applications where full sterilization, easy maintenance, and quick shut-off are essential.

Consider BI-TORQ® Valves

Whether you opt for a ball or a butterfly design, BI-TORQ® Valves are known for their reliability and quality. From NPT valve and flanged valve connections to clamp or weld-end models, you’ll find a broad range of options to suit your specific process demands.

Ready to Choose Your Sanitary Valve?

Selecting the right sanitary valves depends on factors such as process requirements, pressure ratings, product compatibility, and budget considerations. To explore a comprehensive range of both ball valve and butterfly valve options for your facility, visit our Valve Category Page.