Brewer Hardware: A Guide for Serious Brewers

Brewing has become more accessible than ever before, and today we’ll discuss some of the basics that you need to know.

It doesn’t matter if you’re brewing from home or working in a large-scale environment — understanding brewer hardware can help make you more professional and proficient.

Plus, knowing the hardware needed to make your favorite IPA or imperial stout will improve your beer game.

What Are 3-A Standards?

3-A standards are a baseline that meets USDA (United States Department of Agriculture) and FDA (Food and Drug Administration) requirements. This is the guideline manufacturers of food-grade hardware must follow.

3-A standard hardware consists of stainless steel connections and fittings, as these have a food-grade surface for sanitization.

Pro-Tip: High-quality food-grade stainless steel has wider temperature ranges. This helps prevent rust, which can contaminate food products.

Why Are 3-A Standards Important to a Brewer?

Did you know? Hardware that adheres to 3-A is easier to assemble and disassemble. Thus, it’s ideal for food-based manufacturing.

This benefit makes sanitization, inspection, and maintenance a far easier prospect. Even more so when compared to non-standard parts (with stricter adherence to surface cleanliness).

Any brewer will tell you that regular maintenance and cleaning is essential — especially in the brewing process. Yeast strains can change the taste of your beer, and you won’t want an old IPA strain to ruin your new cream ale.

By buying hardware that meets 3-A standards, you’re making your life easier in the long run.

According to the Master Brewers Association of the Americas (MBAA), in 2011, the FDA signed into law “the most sweeping reform in food safety in over 70 years.”

Adherence to these standards isn’t only crucial for public safety; it’s also the law.

What Types of Brewing Hardware Exists?

Besides a brewing kettle, a recipe, and practice, you need to be familiar with various types of hardware. This is even more prominent when moving into more professional production.

Yet, you may be surprised to learn that finding the correct hardware comes down to choice and necessity. Why? Because most brewers’ hardware is standardized.

The Hardware Fittings

Stainless steel fittings are the glue that holds everything together, and can be broken down into the following types:

- Tri-clamp

- I-Line

- DIN style

- Butt-weld

- Bevel seat

We’ll discuss these types of fittings before continuing onto other types of hardware.

Of particular note, when looking at hardware, you may come across the term “National Pipe Tapered” (NPT) or “National Pipe Straight” (NPS). Instead of reinventing the wheel, we’ll let John, co-owner at Sanitary Fittings, describe it:

“The tapered version has a thread that when viewed from the side is tapered whereas the straight version is not. The benefit of utilizing the tapered version is that in most cases the tapered version can be secured without the need for tightening tools beyond hand strength and plumbing tape” — John Zabkowicz

Tri-Clamp Fittings

Some of the most common and popular types of stainless fittings are tri-clamp, also known as tri-clover. These have a practical and straightforward design.

Using a gasket and clamp, the tri-clamp system creates a leak-proof environment for your favorite beverage.

Tri-clamp fittings connect flush against each other, with a gasket seal in-between. They are held firmly together by a clamp, which completes the assembly. Elegant and low maintenance, this is the industry standard.

Because the design is so simple, this means sanitization and assembly are quick. Even replacing gaskets is a breeze, making these fittings great long-term investments.

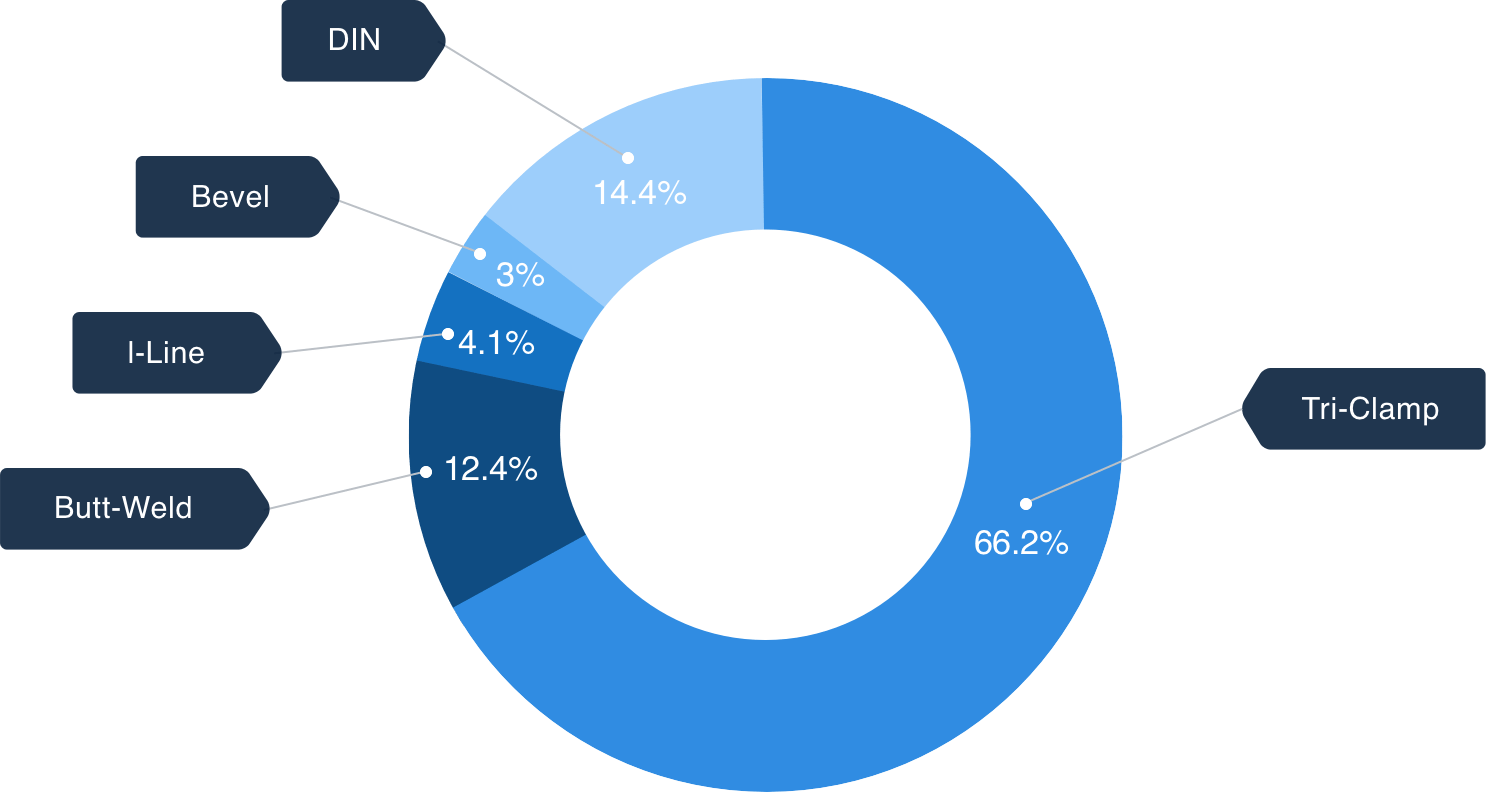

“67% of fittings sold within the United States are tri-clamp.” — Bryan Wells, President of Steel & O’Brien Manufacturing

Tri-clamp fittings come in a variety of designs and sizes to fit every possible need. In our selection, there are reducers, elbows, laterals, and much more. You can design the perfect brewing system for just about any need.

You may hear the term “tri-clover” when discussing fittings. Generally, the term is interchangeable with tri-clamp. Without going into historical context, both stainless connectors are essentially the same.

I-Line

Like tri-clamp stainless steel fittings, these use an alternative flange-face design.

They’re less common than the tri-clamp, which has swept across the industry, but this is an option that you should know about since many brewers use it.

I-Line fittings use interlocking male and female connections. These have gaskets, allowing for higher temperatures, vibration, and pressure.

DIN Style

The German Institute for Standardization (DIN) created this type of stainless fitting. It has since become commonplace in Europe — using a metric standard befitting their European roots.

Since a lot of beer styles originate in Europe, and even more in Germany, your budding brewery could use these to offer a more authentic brewing process. Using DIN fittings also makes collaborative efforts easier, if you’re brewing with Europeans.

Butt-Weld

These are standard stainless steel fittings that offer a more permanent solution for your brewing needs — they are welded into place, and so need an on-site welder.

If you’re operating in a low-traffic area or don’t expect to alter your setup much, butt-welded fittings can be a cost-effective solution.

Bevel Seat

Bevel seat fittings are like I-Line, and — while the least common — they use a stainless nut and gasket design.

This may be a desirable alternative for those seeking the benefits of higher pressure and temperature.

What Else Should I Know?

Below, you can see the popularity of various fittings.

When you know what kinds of stainless fittings you want, you have to discover the hardware associated with those fitting types.

For example, before you attempt to add a tri-clamp tube to a series of ball valves, you first need to understand what the terminology means.

We can break down the basic hardware into tubing, valves, fittings (discussed above), hoses, and strainers for the time being. For reference, you can check these out in our collection as we discuss each.

The Basic Hardware

Tubing

As this is the most simplistic brew hardware you can get, there isn’t much detail to go into. Made of stainless steel for processing requirements, tubes often come in various spool lengths and diameters. You can get them in various standard fittings, as noted above.

Many brewers’ hardware suppliers also provide tube hangars, giving you a more secure way to attach and organize your brewing setup safely. Plus, some of these use brass fittings, which can add a bit of flair to how everything looks.

There are two ways to find tube dimensions. We made a video at Sanitary Fittings with a straightforward explanation for you:

Valves

Valves can come in a variety of designs to suit your particular needs. Whether you need to reduce interior tank pressure with a relief valve during fermentation or introduce clean water with a simple ball valve, valves are an important component of your hardware.

Quality stainless steel fittings should fit valves and match the style you desire. A suitable valve should be leak-free, operate efficiently, and be simple to clean. They’re also available in various types of seating material and handle colors.

The most common types of valves are ball valves and butterfly valves. The former is a ball with a hole drilled through it, allowing flow when rotated. The latter is a disk that turns on a shaft.

Ball valves offer less all-around resistance and can maintain pressure more efficiently, while butterfly valves are generally cheaper and easier to maintain.

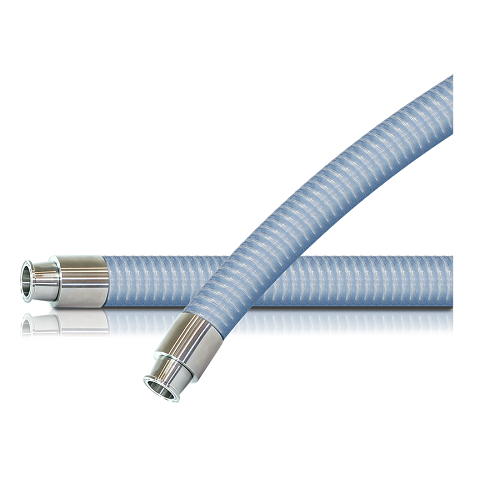

Hoses

Food grade hoses allow you to transport the beverage from one place to another. They do so while offering flexibility and cost-effectiveness.

These must be USDA and FDA compliant and can come in various lengths and fittings to pair with the rest of your brewers’ hardware.

Quick disconnects are easy with quality hoses that use stainless connectors. These are made from various materials with different temperature ranges.

Sometimes hoses are made for the type of beverage you’re moving, such as wine or beer, making for more diverse options in your setup.

Strainers

The last of the brewers’ hardware we’ll be discussing are stainless strainers. These provide another tool in your hardware toolbox.

Whether being used as tank sprayers or mesh filtration, they improve the product’s purity and quality.

Even mesh overlays should be made with high-quality stainless steel. They should also come in various sizes and lengths, thus allowing for better control throughout the brewing process.

Start Your Brewer Journey Today

Once you understand the terminology associated with the hardware, you’ll go a long way towards creating the perfect brewing setup.

The standards on brewers’ hardware are run industry-wide. This allows you to walk into any brewery and recognize the equipment being used by more advanced brewers.

Many brewers like discussing their craft — they appreciate knowing some of the hardware may lead to wonderful conversations while enjoying a well-made libation.

Should you find yourself working among brewmasters, you now have value-added knowledge for your job.

There are many guides in the brewing industry, but very few seem to discuss the nuance of the hardware itself used to produce your favorite ales. If you would like to continue your education, check out our Ultimate Guide to Tri-Clamp fittings.

You’ll want to know which fittings and tubes would work together, in which case we can refer you to another valuable guide on Sanitary Fittings Dimensions where we give a more in-depth understanding of how to measure properly.

Further, our blog discusses and addresses other concerns of food-grade equipment.

Now get out there, brewer! There’s plenty of work to do, and we’re all looking forward to a nice ale.