Understanding Sanitary Compression Fittings

Sanitary compression fittings are specialized connectors designed for the hygienic transfer of fluids in various industries, including pharmaceuticals and food and beverage. Unlike traditional fittings, sanitary compression fittings are designed to minimize dead spaces, prevent bacterial growth, and facilitate easy cleaning and sterilization.

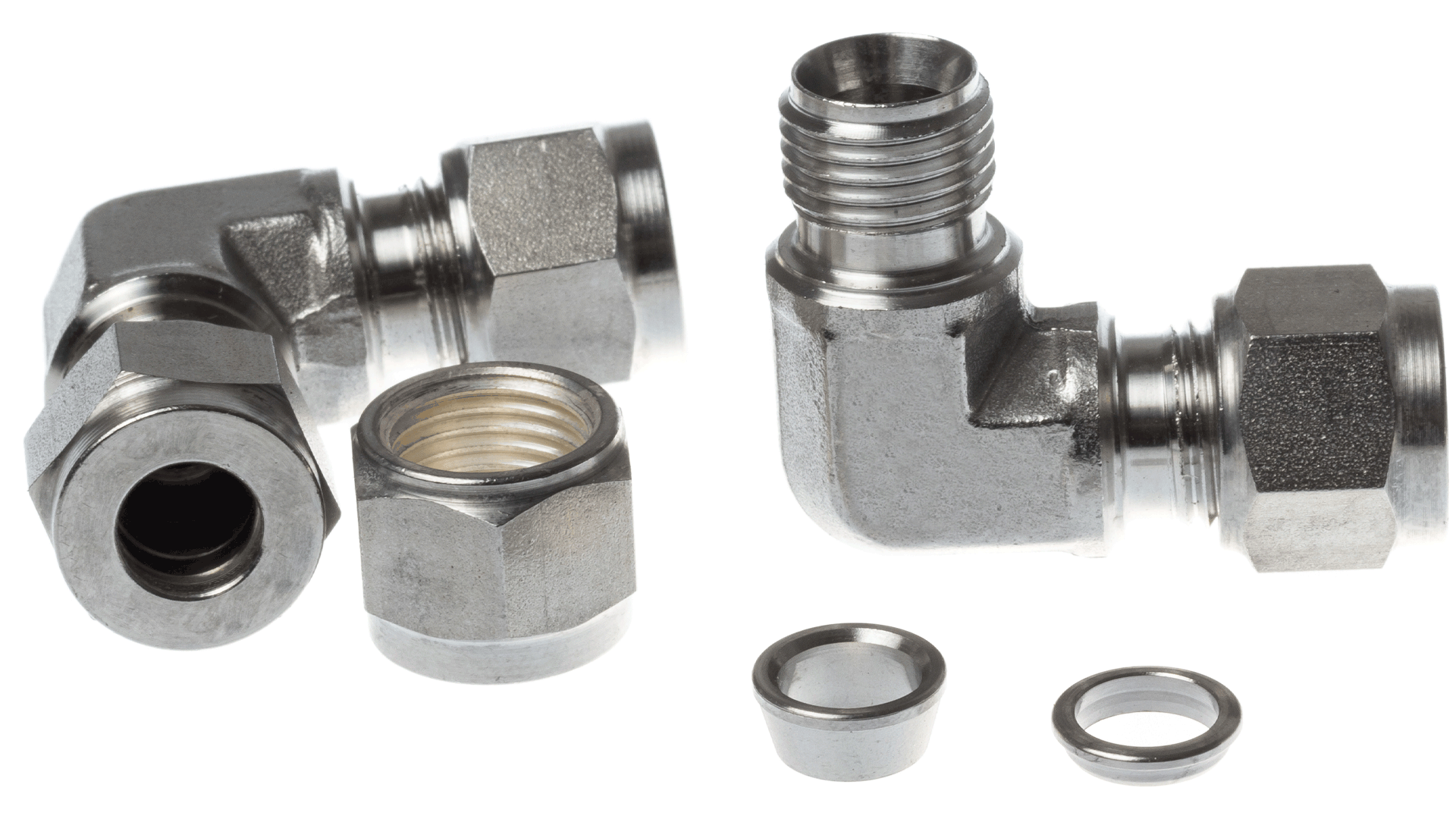

These fittings typically consist of two components, a nut and a ferrule, that when properly assembled, create a secure, leak-proof connection. The nut is tightened onto the fitting, compressing the ferrule around the tubing or pipe, creating a reliable seal. This design ensures a smooth surface without threads or crevices that could harbor contaminants, making sanitary compression fittings ideal for applications where cleanliness and purity are non-negotiable.

Why Sanitary Compression Fittings are Important

- Hygiene and Contamination Prevention: The primary purpose of sanitary compression fittings is to maintain a clean and sterile environment. By eliminating potential areas for bacterial growth and contamination, these fittings contribute to the overall safety and quality of the end product.

- Ease of Cleaning: Sanitary compression fittings are designed with simplicity in mind. Their smooth surfaces and minimal components facilitate easy disassembly and cleaning, reducing downtime and ensuring a quick turnaround between production cycles.

- Versatility: Whether used in the pharmaceutical industry for drug manufacturing or in the food and beverage sector for processing consumables, sanitary compression fittings provide versatility in connecting various components within a system.

When to Use Sanitary Compression Fittings

- Critical Processes: Sanitary compression fittings are indispensable in processes where maintaining the purity of the product is critical. This includes pharmaceutical production, biotechnology research, and the manufacturing of high-quality food and beverages.

- Highly Regulated Industries: Industries subject to strict regulatory standards, such as the pharmaceutical and food sectors, benefit from the use of sanitary compression fittings. These fittings ensure compliance with hygiene and safety regulations.

- Batch Processing: Sanitary compression fittings are particularly well-suited for batch processing, where frequent cleaning and changeovers are necessary. Their ease of disassembly and reassembly streamlines these processes.

The Role of Tube Adapters

While sanitary compression fittings are designed to provide a secure connection between components, they may not always be directly compatible due to differences in tubing sizes or types. This is where tube adapters come into play.

Tube Adapters: Bridging the Gap

Tube adapters serve as intermediaries, enabling the seamless connection of different tubing sizes or types. Whether transitioning from stainless steel to plastic tubing or connecting tubes of varying diameters, tube adapters play a crucial role in maintaining the integrity of the sanitary system.

By ensuring a smooth and secure transition between components, tube adapters enhance the versatility of sanitary compression fittings. They allow engineers and operators the flexibility to adapt their systems to specific requirements without compromising on the fundamental principles of cleanliness and sterility.

The Takeaway

When precision, hygiene, and ease of use are your main goals, sanitary compression fittings the go-to fitting and tube adaptors help bridge the gap between different sizes or types of tubing. Their seamless design and functionality make them indispensable in industries where product integrity is non-negotiable. The addition of tube adapters further enhances the flexibility of these fittings, allowing for the efficient connection of different components within a sanitary system.