Only then can you ensure the proper pressure and flow needed to meet your needs and run your pump system efficiently. This holds true whether you’re using a new pump or modifying an existing one.

However, guessing at or visually estimating your pump capacity won’t cut it. Visual estimations are rarely accurate and don’t account for specific variables, such as viscosity and dynamic head, that will affect your pump system’s performance.

Today, we take a look at pump capacity and shed some light on important topics, including:

- The components that make up pump capacity

- How to accurately work out your flow rate

- Essential data to help define pump capacity

Step 1 – Get Familiar With the Capacity Calculation Units

Pump capacity describes the rate at which a pump can push fluid through its system and is expressed as fluid volume per unit of time. The flow, or pump capacity, is usually represented by the letter Q, with some of the most commonly used units being:

- gpm (gallons per minute)

- m3/s (cubic meters/second)

- L/s (liters/second)

- m3/h (cubic meters/hour)

The conversion relationship between these above examples is as follows: 1 m3/s = 1000 L/s = 3600 m3/h = 15,850.3231 gpm.

Pump capacity can also be expressed as the mass of a fluid that passes through a pump over a given time—also known as the mass flow rate.

In this expression, the volume flow rate is associated with the mass flow rate through the following equation:

M = ρ x Q

Where: M = mass flow rate in kg/s or lbs/s

ρ = the density of the fluid (kg/m3, lb/ft3, l/ft3)

Q = the volume flow rate (gpm, L/s, m3/h)

Therefore, the association between volume flow rate and mass flow rate can be represented by: Qm = pQ.

Step 2 – Understand Your Key Data Points and Terminology

To calculate your pump capacity accurately, you need to understand some key data points and terminology. These include:

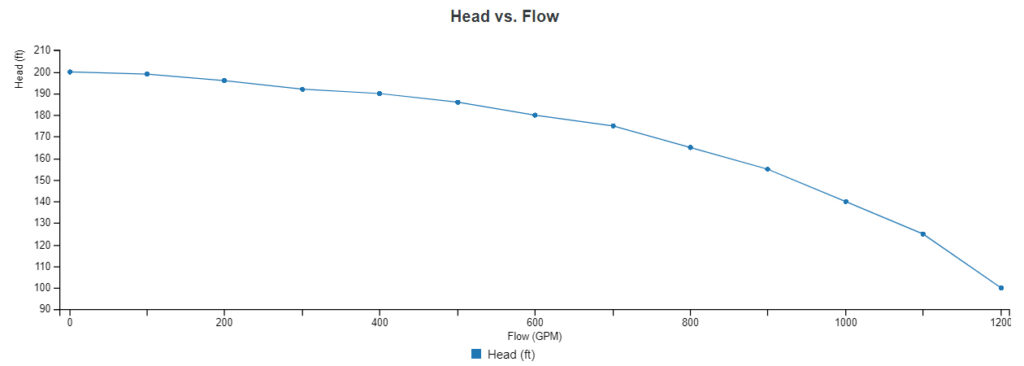

- Head: Refers to the vertical height difference in which you’re trying to move the fluid. Specifically, it is the measure of pressure exerted by the fluid expressed in feet.

Centrifugal pump manufacturers typically provide pump curves (sometimes tables) showing the head (usually for water) with specific gravity = 1.

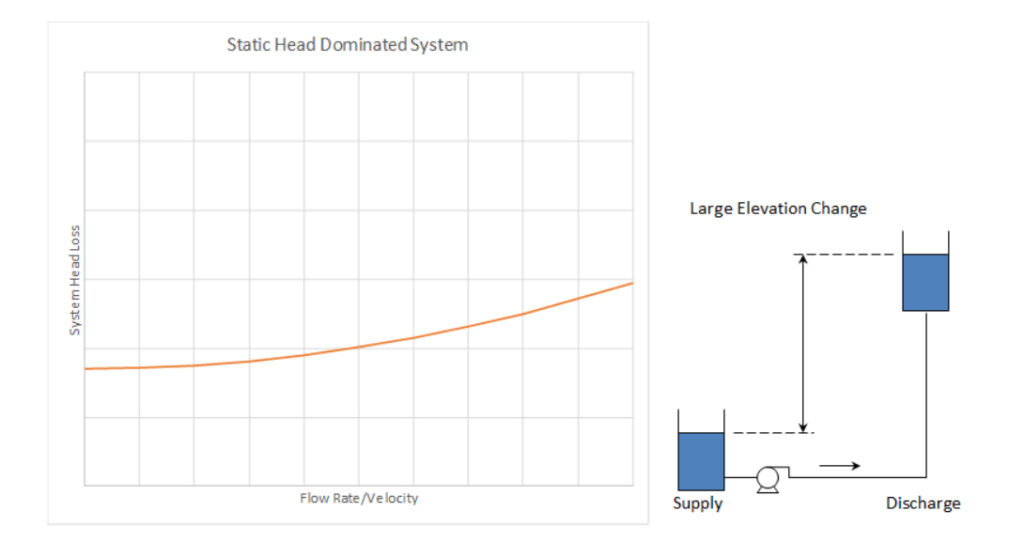

- Static head: Refers to the vertical height difference from the surface of your water (or liquid) source to the center line of your pump’s impeller.

The vertical difference from the surface of your fluid source to the discharge point is the total static head.

- Total (dynamic) head: Total dynamic head is determined through the summation of the static head (total vertical difference), the friction losses, and demand pressure from nozzles (total discharge head). That is:

Total dynamic head = static head + friction head loss + pressure head - Capacity/flow: Calculated as the amount of time it takes to move a specific volume of liquid, usually measured in gallons per minute (gpm). The amount of liquid your pump will move is determined by the width of the impeller and the shaft speed.

Note: As per centrifugal pump laws:- Capacity/flow rate is directly proportional to pump speed

- Discharge head is directly proportional to the square of the pump speed

- Required pump power is directly proportional to the cube of the pump speed

- Brake horsepower (BHP) and capacity: BHP refers to the total power it takes your pump to do a specific amount of work. As such,

BHP increases as you increase the capacity.

BHP = Q x h x Sp.Gr/3960 x Efficiency

Where:

Q = Your pump capacity

h = Your pump’s head

Sp. GR = Specific gravity of the liquid being pumped

BHP = Horsepower needed by the pump

Note: 3960 is a constant related to horsepower; that is, (33,000 ft-lbs/min) with 8.33 lbs/gallon of water.

33,000 / 8.33 (water’s density) = 3960 - Viscosity: This is a measure of a liquid’s resistance to flow. It determines the type of pump you can use and how fast it will run.

Pump capacity, head, and efficiency have an inverse relationship with viscosity. That is, they decrease at high viscosity.

Conversely, power will increase at high viscosity.

Step 3 – Plug Your Data Into the Flow Calculation Formula

Flow rate (Q), or pump capacity, is expressed as:

Cubic meter/hour (m3/h), liter/sec (L/s), L/s = 3.6 m3/h = 0.06 m3/min = 60 L/minG = Qρ

Where G is the weight, and p is the liquid-specific gravity.

The shaft power of the pump = water supply (liter/sec) × head (m) / 102 × efficiency = flow × head × density × gravity acceleration.

Pump efficiency = Pump effective power / Pump shaft power

Head refers to the maximum height a fluid may be pumped for a particular application and is indicated by (h), measured in meters (m).

Pump efficiency refers to the ability of your pump to convert input power from the shaft into effective power, denoted by P.

Pump efficiency η (%) is calculated using the following formula:

η = Pout / Pin (2)

Where:

η = efficiency (%)

Pin = power input

Pout = power output

Head (h) can be defined using the formula:

h = (p2 – p1) / (ρ g) + v22 / (2 g)

Where:

h = total head developed (m)

p2 = pressure at outlet (N/m2)

p1 = pressure at the inlet (N/m2)

ρ = density (kg/m3)

g = acceleration of gravity (9.81) m/s2

v2 = velocity at the outlet (m/s)

Here are a couple of videos to help you better understand how to apply these formula through real world examples:

Discover Sanitary Fittings: Your Pump Solutions Experts

Feeling a little lost? Reach out to the experts at Sanitary Fittings. We’re more than happy to help.

Sanitary Fittings is a customer service oriented company that provides stainless tube fittings and pump solutions to food, beverage, and pharmaceutical industries.

We do this through partnerships with accredited manufacturers and associations. One such partnership is with TOP-FLO®, a proven name in the sanitary process equipment industry with a reputation built on quality and durability.

Sanitary Fittings stocks TOP-FLO® pumps designed for the high-efficiency transfer of products over a wide range of head and viscosity conditions.

We stock pumps ideal for various small and medium-sized applications across various industries, including CIP (clean-in-place) installations.

But that’s not all; Sanitary Fittings is also dedicated to providing the best customer experience. Our full-service capability makes us the perfect partner for any project; no minimum orders and no hassle.

This also means we can provide a full range of services, including:

- Maintenance of stainless steel fittings for different industries

- Overhauls and replacement of existing systems for less

- Repairs on all parts under our 90-day warranty

We also provide a host of valuable information through our blog. This helps educate our customers, making them feel more confident about doing business with us.

But don’t take it from us. Here’s what a few happy customers had to say:

“The tech support during the order was fantastic. The buying process was great, and they helped me get the correct fitting with expedited shipping.”

– ★★★★★ | Michael Homma

“As always, Sanitary Fittings provides a quick turnaround on quality products. Looking forward to our next interaction.”

– ★★★★★ | Peter Roettger

“All parts were as expected and delivered quickly. Pricing was very good, and the drawings were extremely helpful for my project.”

– ★★★★★ | David Morse

Visit Sanitary Fittings for all your pump-related queries and the best deals on pumps and parts.

83C Stuffing Box |

TF-C216 Centrifugal Pump |

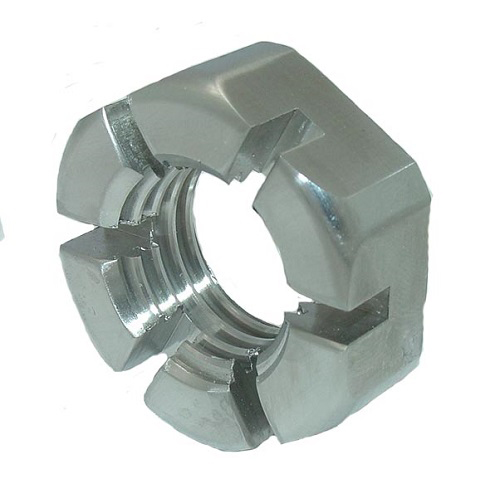

Castellated Nut (Acme Thread) |

Frequently Asked Questions

Why is pump capacity important?

Pump capacity will determine the type of pump you need for a particular application. It also dictates pump performance, including how long it will take to complete a task.

The higher the pump capacity, the higher the volume of fluid your pump can move. Conversely, a low pump capacity means it will take more time to move an equal amount of fluid.

Since high-capacity pumps are more expensive, it’s important to strike the perfect balance to suit your budgetary constraints and application needs.

What is Net Positive Suction Head?

Net Positive Suction Head (NPSH) refers to the head of the fluid required at the pump suction end above the vapor pressure of the liquid at that point.

It’s an essential element in pump selection and setup as it relates to a troublesome phenomenon known as cavitation. If left unchecked, cavitation can have damaging effects on a pump’s delicate internals and may result in reduced performance and reliability.

What is cavitation, and why does it matter?

Cavitation refers to air pockets or voids in pumped liquids that result from bubbles taking up space, which lead to a drop in pump capacity.

Collapsing bubbles can damage your pump’s impeller and volute, causing significant problems for your pump and its mechanical seals.

Share on LinkedIn: