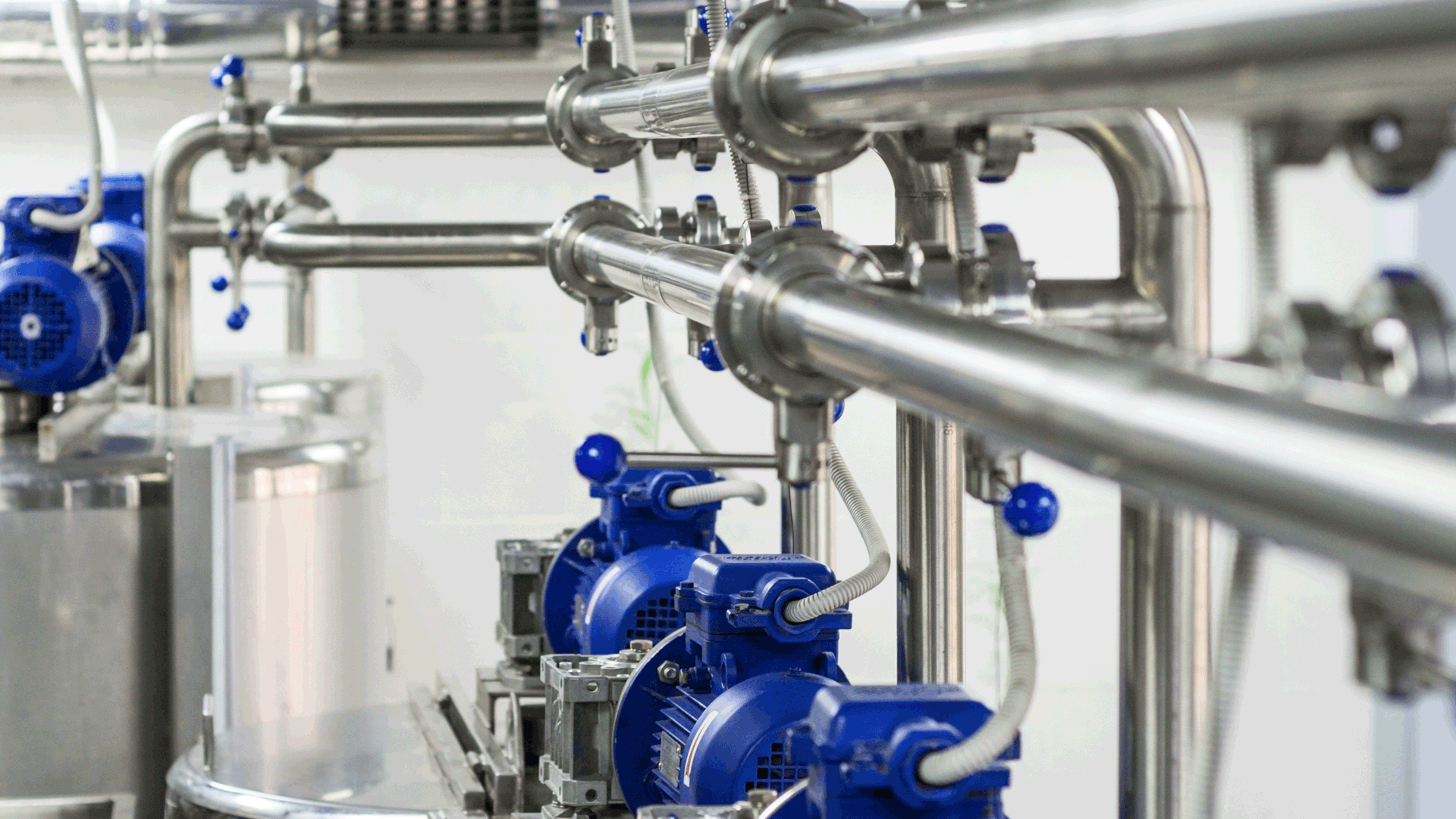

In sanitary applications, where cleanliness and hygiene are the most important elements, selecting the right check valve is crucial. Whether you’re working in the food and beverage industry, pharmaceuticals, or any other field where sanitary conditions are essential, choosing the appropriate check valve ensures the integrity of your processes. From preventing backflow to maintaining product purity, the right valve can make all the difference. In this guide, we’ll walk you through the key factors to consider when selecting a check valve for your sanitary application.

If you’re looking for more information on the different types of check valves, we have more information on our blog post, “Understanding the Different Kinds of Check Valves”.

- Material Compatibility: The first consideration in selecting a check valve for sanitary applications is material compatibility. Ensure that the valve materials are compatible with the substances being transported. Stainless steel, particularly 316 stainless steel, is a common choice due to its corrosion resistance and durability. For applications requiring even higher purity, options such as sanitary-grade plastics or elastomers may be suitable.

- Hygienic Design: Look for valves with a hygienic design that minimizes areas where bacteria or contaminants can accumulate. Smooth surfaces, polished finishes, and crevice-free constructions are essential features to consider. Valves with minimal dead space or internal irregularities are easier to clean and sterilize, reducing the risk of contamination.

- FDA Compliance: If your application involves food or pharmaceuticals, ensure that the check valve complies with relevant industry regulations such as those set forth by the Food and Drug Administration (FDA) or other regulatory bodies. Valves labeled as “FDA compliant” or “USP Class VI certified” are typically suitable for sanitary applications where product purity is critical.

- Operating Conditions: Consider the operating conditions of your application, including pressure, temperature, and flow rates. Select a check valve that can handle the specific conditions without compromising performance or integrity. High-quality valves are designed to operate reliably across a range of pressures and temperatures, ensuring consistent performance in sanitary applications.

- Size and Connection Type: Choose a check valve size and connection type that aligns with your existing piping system. Common connection types for sanitary applications include tri-clamp, weld ends, and sanitary flanges. Ensure proper compatibility and consider factors such as pipe diameter and flow requirements when selecting the valve size.

- Performance Requirements: Evaluate the performance requirements of your application, such as flow characteristics, cracking pressure, and sealing capabilities. Different check valve designs offer varying performance features, including swing check valves, ball check valves, and diaphragm check valves. Consider the specific demands of your application to determine the most suitable valve type.

- Ease of Maintenance: Opt for check valves that are easy to install, inspect, and maintain. Valves with quick-release clamps or tool-less disassembly simplify maintenance procedures and minimize downtime. Additionally, choose valves from reputable manufacturers known for their quality construction and reliable performance.

- Cost Considerations: While cost shouldn’t be the sole determining factor, it’s essential to consider the overall value provided by the check valve. Balance the initial investment with factors such as durability, longevity, and performance to ensure the best long-term solution for your sanitary application.

Selecting the best check valve for your sanitary application requires careful consideration of various factors, including material compatibility, hygienic design, regulatory compliance, operating conditions, size, performance requirements, ease of maintenance, and cost. By thoroughly evaluating these factors and choosing a high-quality valve from a trusted manufacturer, you can ensure the integrity and purity of your processes while maintaining optimal efficiency and reliability.

Remember, when it comes to sanitary applications, investing in the right check valve is an investment in the success and safety of your operations. Sanitary Fittings is happy to offer an assortment of check valves and replacement parts.