Sanitary Fitting Elbow Radius Bend Formula

Answer: We get this question every so often from customers. Usually, the issue they are trying to overcome is a lack of space either above or below the two process lines they are trying to connect. The short answer to this question is “yes”, we do offer alternatives to 90 degree elbow bends but it’s probably not what you’re looking for.

We do offer 45, 88, and 92-degree elbow bends in both butt-weld and tri-clamp styles. Of these sizes, 45-degree is the most popular. However, if you are short on space in either direction none of these angles is going to be of much help.

So what is holding us back from creating elbows with more extreme angles? For starters, any elbow with a bend greater than 92 degrees is no longer considered “sanitary”. Meaning that with an angle exceeding 92 degrees, the possibility opens up that process media can pool which opens up a whole can of worms related to cleanliness or process lines.

The other issue related to creating larger degree bends in elbows relates to the outside diameter of the tube. A sanitary tube cannot be bent much more than 1-1/2 times the outside diameter of the tube without causing undue strain to the wall of the tube itself.

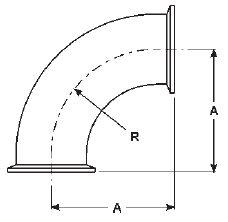

| Fitting Radius Bend = Fitting Outside Diameter (OD) x 1.5 |

For example, a 2-1/2″ OD tube fitting has a maximum bend-radius of (2.5″ x 1.5″) or 3.75″. For additional information on sanitary elbows and bend radii, please reference the table below.

|

| Size (Tube OD) | Bend Radius (R) |

|---|---|

| 1/2″ | 1.125″ |

| 3/4″ | 1.125″ |

| 1″ | 1.5″ |

| 1-1/2″ | 2.25″ |

| 2″ | 3″ |

| 2-1/2″ | 3.75″ |

| 3″ | 4.5″ |

| 4″ | 6″ |

| 6″ | 12″ |

| 8″ | 15″ |

Have more questions? Please contact us!