Sanitary Pumps and Pressure: 3 Simple Tips on How They Work

Industrial processing pipeline systems rely on sanitary pumps to pump hygienic liquids, colloids, and slurries.

Sanitary pumps are critical in transporting products meant for human contact or consumption, or in operations where cleanliness is mandated or desired. Examples of such areas include:

- Food

- Beverages

- Dairy products

- Pharmaceuticals

These pumps have smooth internal surfaces that are easy to clean and sanitize. This design helps prevent or minimize the buildup of bacteria, mold, and other microorganisms, ensuring zero product contamination.

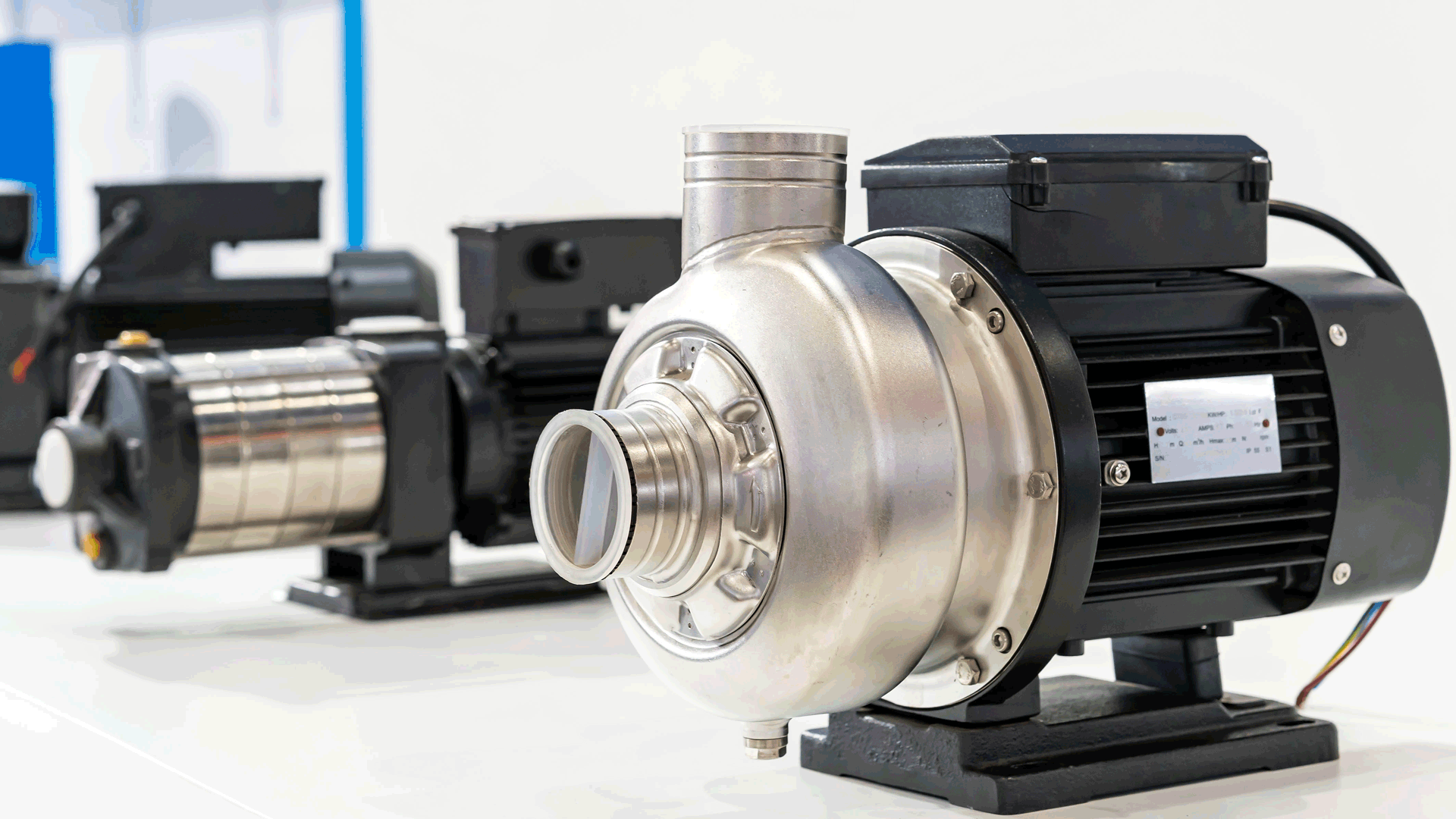

There are different types of sanitary pumps, and each one has its own features and benefits. The four basic sanitary pumps are:

- Centrifugal pumps: These sanitary pumps rely on the transfer of rotational energy from impellers to move liquids and slurries. They’re typically used to move large volumes of low viscosity fluids quickly.

- Positive displacement pumps: These pumps use gears, impellers, or rollers to move fluid from an expanding cavity (suction side) to a decreasing cavity (discharge side). As the fluid exits, the vacuum it creates draws in more fluid.

- Airlift pumps: These sanitary pumps mix air with the fluid so that this mixture, which is lighter than the liquid itself, can rise in the pipes and get discharged above the liquid’s level.

- Jet pumps: These pumps force fluids through a nozzle in a process where the fluids’ energy is converted into velocity energy.

Centrifugal and positive displacement pumps are the most commonly used pumps in sanitary applications.

We’ll go over a few simple tips about how centrifugal pumps work to generate pressure and discuss how you can troubleshoot their most common issues.

1 – They Rely on Centrifugal Force

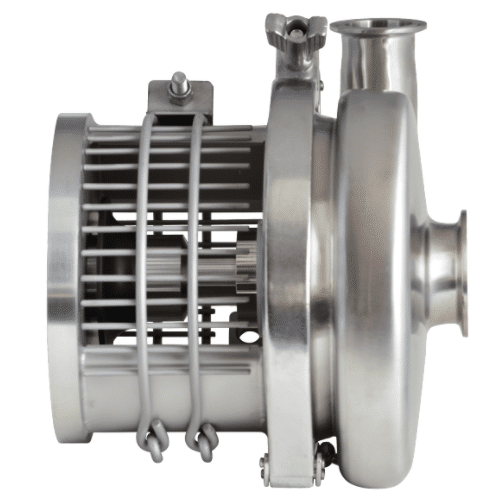

A centrifugal sanitary pump uses an impeller to draw fluid from the center of the pump and then flings it outwards into a holding chamber. This spinning action causes centrifugal force, which propels the fluid through the pump and out of the outlet valve or discharge nozzle at high pressure.

For a centrifugal pump to work properly, there must be a balance of forces.

The fluid must enter the pump at the right speed and pressure so that it can be accelerated by the spinning impeller without damaging the pump. The discharge nozzle must also be the correct size so that the fluid can exit at the right speed and pressure.

The main components of centrifugal pumps are:

- Impeller: Gives the fluid its initial spin. The type of impeller (open or closed) will determine how well the pump can handle solids.

- Diffuser or volute: Helps slow down and stabilize the fluid as it exits the impeller.

- Inlet and outlet valves: Regulate the flow of fluid into and out of the pump.

- Stationary casing: Houses all the other components and keeps them in place. It also forces the fluid to discharge from the pump by converting velocity to pressure.

Expert Note: It’s crucial to prime your centrifugal pump before operation, particularly when the fluid level is below that of the impeller. While some self-priming centrifugal pumps exist, standard centrifugal pumps generally need to be primed before operation to work properly.

2 – Their Performance Can Be Affected by Viscosity

The viscosity of a fluid is a measure of its resistance to flow. Fluids with high viscosity, like honey or molasses, flow slowly, while fluids with low viscosity, like water, flow quickly.

Centrifugal pumps are designed to handle fluids with viscosities ranging between 0.1 and 200 cP. For example, milk has an approximate absolute viscosity of 2 cP at 18 degrees Celsius, while sorbitol has a viscosity of 200 cP at 20 degrees Celsius.

Pumping fluids with higher viscosities through a centrifugal pump will force it to work harder, which can lead to reduced efficiency and a shorter lifespan.

If you need to pump a fluid with high viscosity, you’ll need to use a different type of pump, such as a positive displacement pump.

On the plus side, centrifugal sanitary pumps are suited to applications with variable flow rates. You can regulate their flow capacity by throttling and changing the speed of the pump’s driver (impeller speed).

Throttling is one of the most inexpensive methods of flow control available. To implement it, you’ll need an adjustable valve in the discharge piping.

However, there are a few disadvantages of throttling a centrifugal pump, including wasted energy and increased system pressure. Throttle valves make the pumping system less efficient because they reduce pump outflow and increase the upstream backpressure (because the upstream pressure is maintained).

Positive displacement pumps differ from centrifugal pumps in that they produce a constant flow rate, no matter the discharge pressure. Additionally, they can’t be completely throttled since they’re operated against a closed valve on the discharge piping.

Attempts to completely throttle a positive displacement pump, therefore, only increase the pressure in the discharge line until it either bursts, the pump gets severely damaged, or both. By using a variable speed drive, however, you can control the flow rate in this pump.

The key differences between centrifugal and positive displacement pumps are highlighted in the table below.

| Centrifugal Pumps | Positive Displacement Pumps | |

| Flow rate | Variable, based on pressure | Constant despite changes in pressure |

| Mechanics | Creates pressure to ensure flow (pump imparts velocity to the fluid, which results in pressure at the outlet) | Creates flow to ensure pressure (pump captures and transfers confined amounts of fluids from the suction to discharge port) |

| Efficiency | Peaks at the best-of-efficiency point, but decreases at higher or lower pressures | Increases with increasing pressure |

| Viscosity | Efficiency decreases with increased viscosity | Efficiency increases with increased viscosity |

| Inlet conditions | Dry pump won’t prime on its own (there must be some fluid in it to create a pressure differential) | Dry pump will prime on its own (negative pressure is created at the inlet) |

3 – Cavitation and Vibration Can Be an Issue

Cavitation is a common issue with centrifugal pumps. It happens when the fluid drawn into the pump doesn’t have enough pressure to balance out the centrifugal force created by the spinning impeller.

As a result, fluid is drawn into the pump too quickly and becomes vaporized. This vapor then collapses, creating tiny bubbles or cavities in the fluid. These cavities can damage the pump components and reduce the pump’s efficiency.

You can tell when cavitation is happening if your pump starts operating loudly. It tends to sound like rocks or marbles going through the pump, or even loud banging that’s accompanied by pipe vibration.

To prevent cavitation, ensure the fluid that’s being drawn into the pump is at the right pressure and temperature.

Start by properly examining pump suction conditions and calculating the Net Positive Suction Head available (NPSHa). You can also install an anti-cavitation valve in the pump’s inlet line to help regulate the flow of fluid.

Sometimes, centrifugal sanitary pumps can experience excess pump system vibration caused by an imbalance in the fluid entering the pump or by the discharge nozzle being the incorrect size. Other causes include:

- Bent shafts

- Damaged impeller vanes

- Improper installation and foundation

- Misalignment of the pump and driver shaft

Whether your pump vibrates or you suspect cavitation, it’s important to troubleshoot the issue promptly so that it can be corrected.

Otherwise, you may experience reduced pumping efficiency, which means getting less than the typical or expected flow, or suffer pump damage and failure.

Choose the Best Pump for Your Operation

While centrifugal sanitary pumps are widely used in the food, beverage, and pharmaceutical industries, among others, their performance can be affected by:

- Cavitation

- Vibration

- Fluid viscosity

To reduce the impact of these factors, consider the process requirements the pump must fulfill to meet your production and operational needs, including:

- Pressure rating

- Piping diameter

- Maximum and minimum flow rate

- Maximum and minimum temperature

The table below highlights how different centrifugal sanitary pumps compare when it comes to various process requirements.

| TF-C100 Centrifugal Pump | TF-C218 Centrifugal Pump | TF-C328 Centrifugal Pump | |

| Capacity | 10gpm to 65gpm | 10gpm to 450gpm | 10gpm to 620gpm |

| Pressure | 23 PSIG / 54 Foot of Head | 130 PSIG / 300 Foot of Head | 130 PSIG / 300 Foot of Head |

| Viscosity | 200 cP | 200 cP | 200 cP |

| Temperature | 212° F | 212° F | 212° F |

Another important factor to consider when choosing a centrifugal sanitary pump is whether it’s a clean-in-place (CIP) or clean-out-of-place (COP) installation.

CIP pumps, like the ones highlighted in the table above, enable easy self-cleaning without the need for dismantling.

Don’t hesitate to get in touch with our professional pump experts if you need help picking out reliable centrifugal sanitary pumps.

Choosing Sanitary Fittings will leave you raving like Connie Baker:

“Great customer service! If all my vendors were as easy to deal with as you were, my job would go much smoother!”

Share on LinkedIn: