In manufacturing, especially in industries where hygiene is paramount, such as food and beverage production and pharmaceuticals, maintaining quality standards is non-negotiable. In these sectors, even the slightest deviation in process parameters can lead to compromised product quality, potentially putting consumer health at risk. That’s where sanitary gauges come into play, serving as indispensable tools for ensuring precision and reliability in various production processes.

Sanitary gauges, designed specifically for use in hygienic applications, play a critical role in monitoring and controlling parameters such as pressure and temperature. Unlike standard gauges, sanitary gauges are constructed with materials and features that meet strict sanitary standards, including smooth surfaces that prevent bacterial growth and easy-to-clean designs.

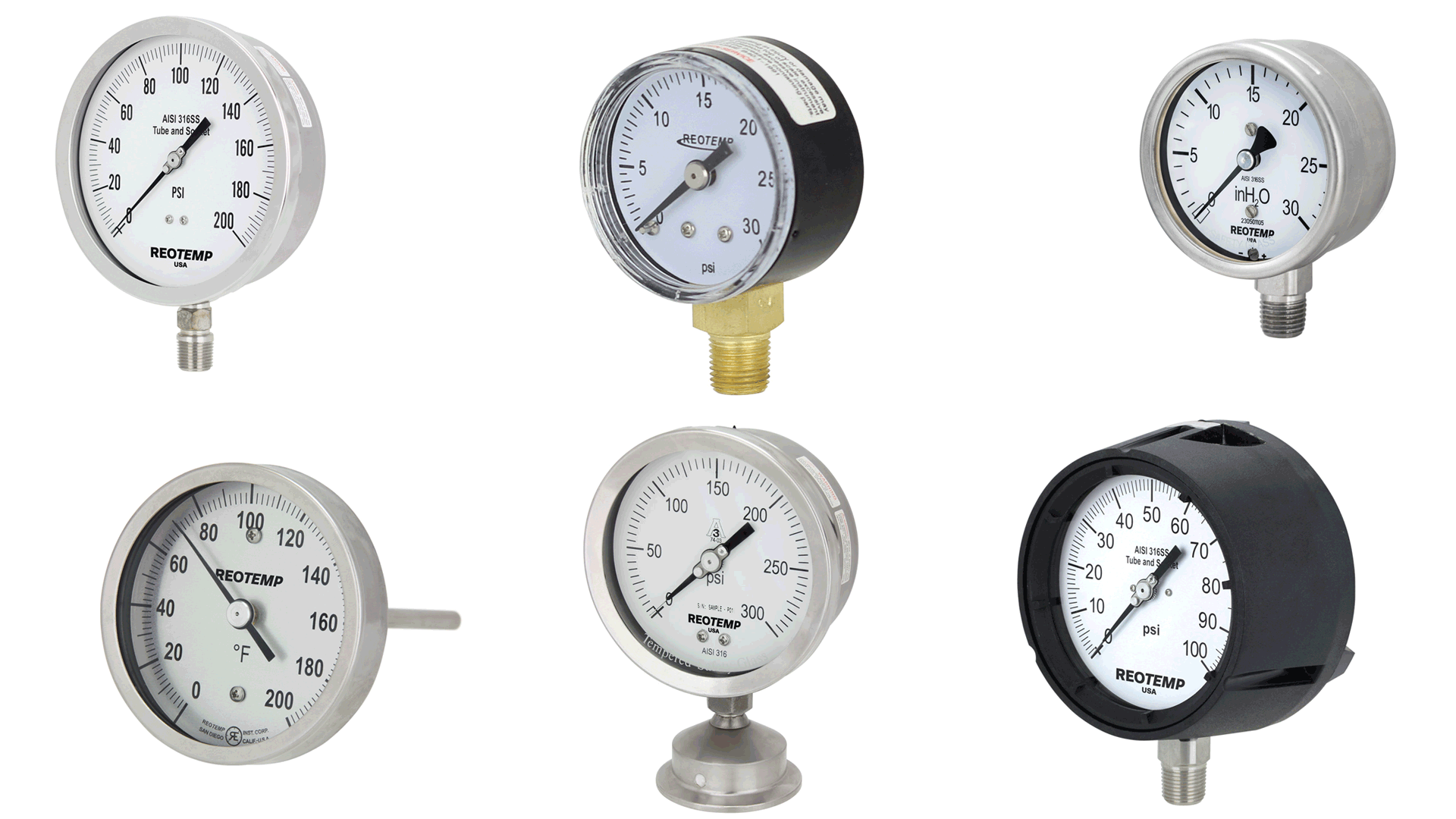

Types of Sanitary Gauges

- Pressure Gauges: These gauges measure pressure within systems and are crucial for maintaining optimal conditions during processes like sterilization, filtration, and filling.

- Temperature Gauges: Temperature control is vital in industries where precise thermal conditions are necessary for product quality and safety.

Importance of Accuracy in Sanitary Gauges

Now, let’s explore why accuracy in sanitary gauges is paramount to product quality:

- Compliance with Regulatory Standards: Regulatory bodies impose stringent guidelines on industries such as food and pharmaceuticals to ensure consumer safety.

- Consistency in Product Quality: Consistency is key in maintaining product quality and brand reputation.

- Prevention of Contamination: In hygienic industries, any risk of contamination can have severe consequences, including product recalls and damage to brand reputation.

- Cost Savings: Accurate monitoring and control provided by sanitary gauges not only ensure product quality but also contribute to cost savings.

The role of accuracy in sanitary gauges cannot be overstated when it comes to ensuring product quality in hygienic manufacturing processes. From pressure and temperature to flow, these specialized instruments play a crucial role in maintaining compliance, consistency, and purity throughout production. Investing in high-quality, accurate sanitary gauges is not just a matter of meeting regulatory requirements but a fundamental step towards upholding consumer trust and delivering products of the highest standard. Sanitary Fittings is happy to offer a wide selection of temperature and pressure gauges.