When it comes to ensuring the safety and quality of products in industries like food and beverage or pharmaceuticals, cleanliness and contamination prevention incredibly important. One critical component in maintaining these standards is the sanitary strainer. But what exactly is a sanitary strainer, when is it used, and how can you choose the right one for your application?

What is a Sanitary Strainer?

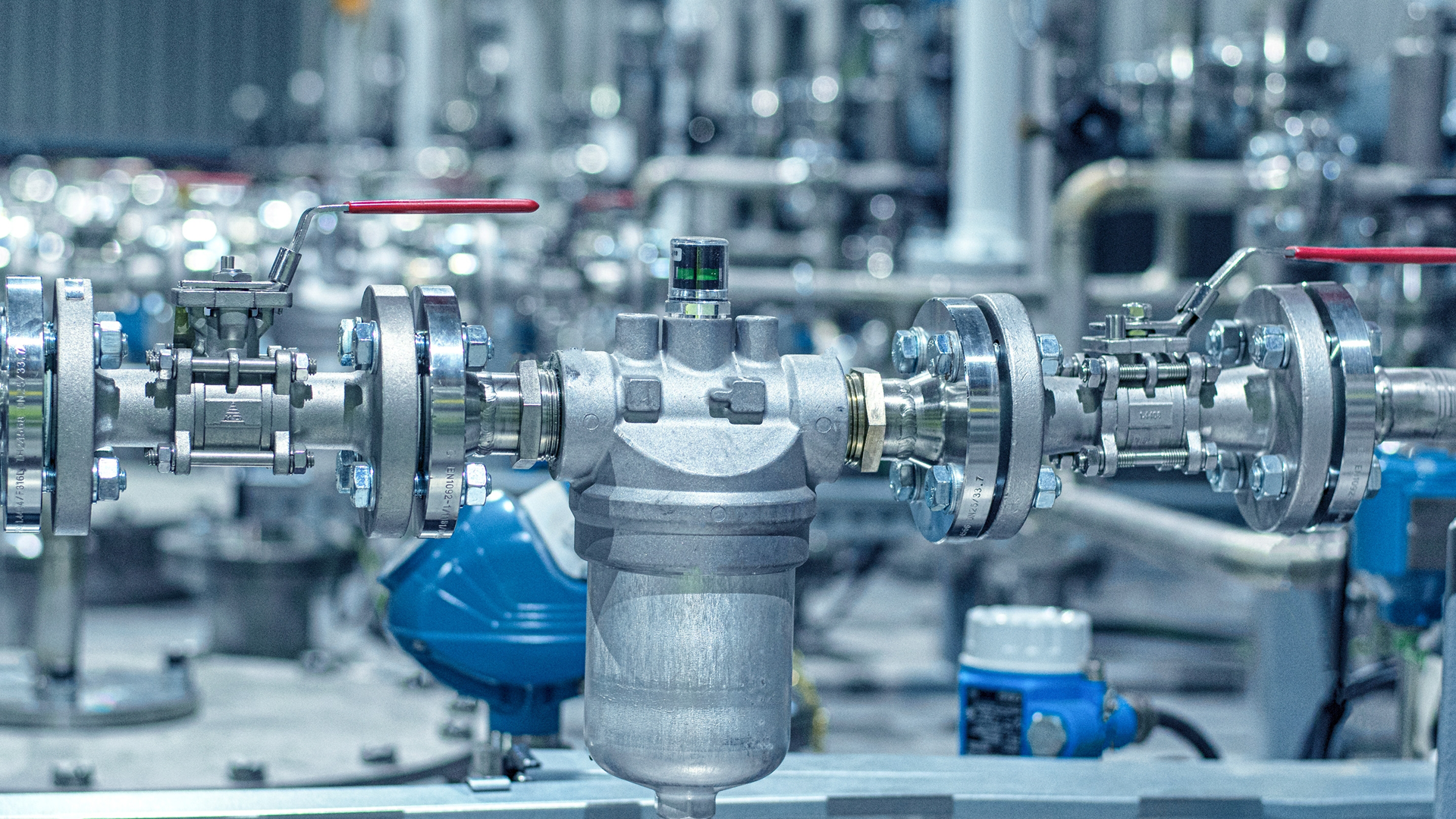

A sanitary strainer is a filtration device used to remove unwanted particles from liquid products to ensure that they meet stringent sanitary standards. These strainers are designed to be easy to clean, often featuring smooth surfaces and crevice-free construction to prevent the buildup of contaminants. They are typically made from stainless steel, which is not only durable but also resistant to corrosion and easy to sanitize.

Sanitary strainers come in various designs, including inline strainers, Y-strainers, T-strainers and basket strainers, each suited to different types of applications. They are essential in processes where the purity of the liquid is crucial, as even the smallest particle can compromise the safety and quality of the end product.

When is a Sanitary Strainer Used?

Sanitary strainers are used in a wide range of applications across various industries, including:

- Food and Beverage Processing: In the food and beverage industry, sanitary strainers are used to filter out solid particles, ensuring that the final product is smooth, safe, and free of contaminants. For example, in brewing, strainers are used to remove hops and other solids from the beer to produce a clear, clean product.

- Pharmaceuticals and Biotechnology: In these industries, maintaining the highest level of cleanliness is critical. Sanitary strainers are used to ensure that the liquids involved in production processes are free from contaminants that could compromise the safety and efficacy of the final product.

- Dairy Processing: Dairy products, such as milk and cheese, require strict filtration to remove impurities and ensure a high level of hygiene. Sanitary strainers help achieve this by filtering out any foreign particles during processing.

How to Choose the Right Sanitary Strainer

Selecting the right sanitary strainer for your application depends on several factors:

- Particle Size and Filtration Level: Consider the size of the particles you need to filter out. Sanitary strainers come with different mesh sizes, which determine the size of the particles they can filter. Choose a strainer with a mesh size appropriate for your application to ensure that it effectively removes contaminants without impeding flow.

- Flow Rate: The flow rate of the liquid through the strainer is another crucial consideration. You’ll need to choose a strainer that can handle your required flow rate without causing excessive pressure drop or slowing down your process.

- Material Compatibility: Ensure that the strainer is made from materials that are compatible with the liquid being processed. Stainless steel is the most common material used for sanitary strainers due to its durability, corrosion resistance, and ease of cleaning.

- Ease of Cleaning and Maintenance: Sanitary strainers must be easy to clean and maintain to prevent the buildup of contaminants. Look for designs that allow for quick disassembly and thorough cleaning, like a non-permanent tri-clamp connection.

- Industry Standards and Certifications: Depending on your industry, you may need to choose a sanitary strainer that meets specific standards and certifications, such as those from the FDA or USDA for food processing, or the ASME BPE for bioprocessing equipment.

The Takeaway

Sanitary strainers are indispensable in industries where product purity is critical. By understanding what a sanitary strainer is, when it should be used, and how to choose the right one, you can ensure that your production process meets the highest standards of safety and quality. Always consider factors like particle size, flow rate, material compatibility, and ease of maintenance when selecting a sanitary strainer to ensure optimal performance and longevity in your application.

Sanitary Fittings is proud to offer multiple sanitary strainer types and different mesh sizes.