When it comes to butterfly valves, the type of seat material can significantly impact their performance, durability, and compatibility with various process fluids. Two of the most popular seat materials—BUNA-N and EPDM—are commonly used in industries ranging from food and beverage to biopharmaceutical. Below, we’ll explore the essential differences, typical chemical compatibilities, and the main pros and cons of each, helping you determine which seat material best meets your facility’s needs.

What Are Butterfly Valve Seats?

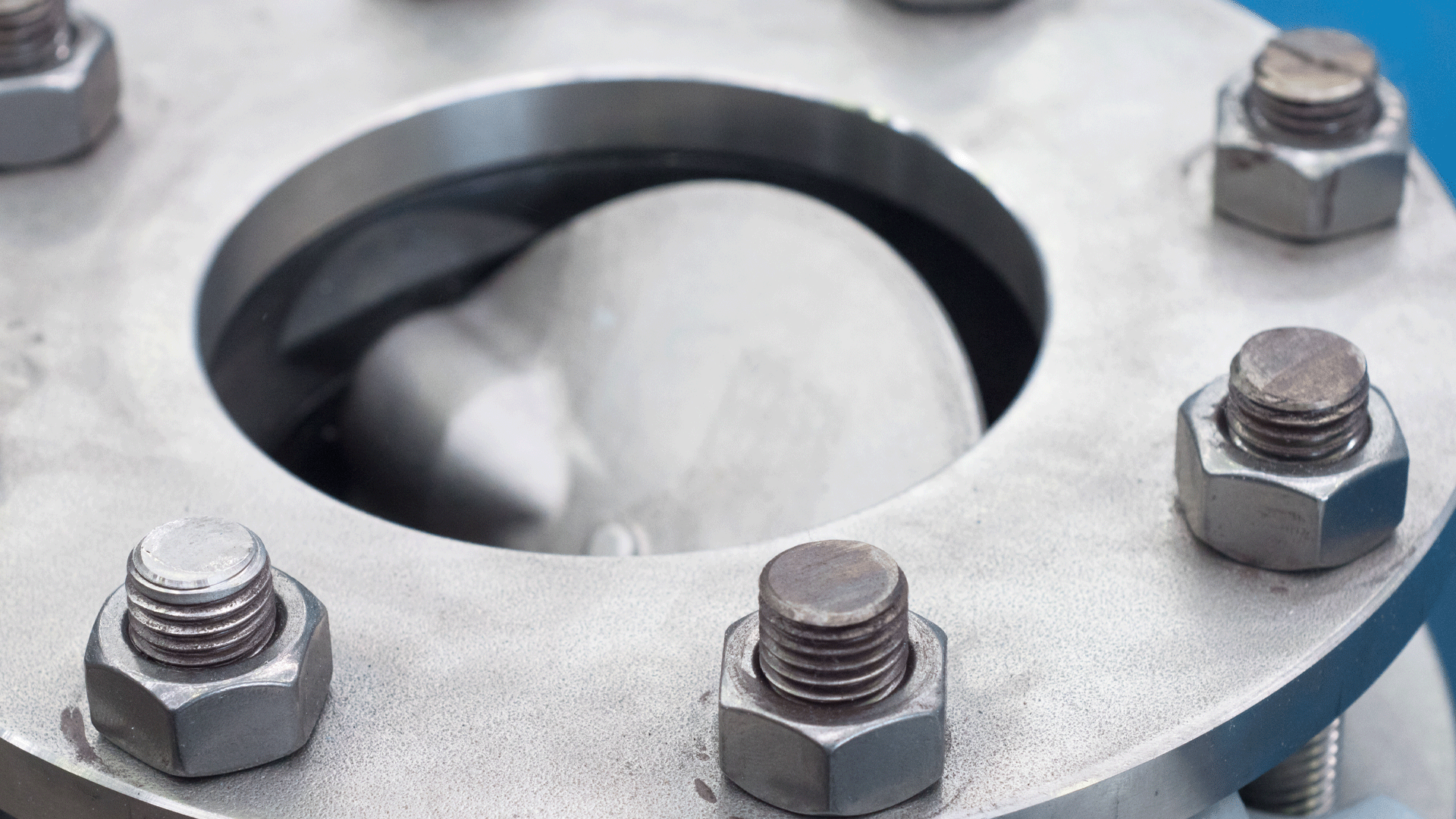

A butterfly valve seat is the sealing surface within the valve that comes into direct contact with the media—whether that’s juice in a beverage plant, a dairy product in a food processing facility, or sensitive fluids in a pharmaceutical environment. Choosing the right seat material is critical to ensuring a reliable seal, maintaining sanitary standards, and maximizing the lifespan of your valves.

BUNA-N (Nitrile) Seats

1. Primary Characteristics

- Well-known for excellent resistance to oils and many hydrocarbons

- Effective in moderate temperature ranges

- Typically cost-effective

2. Common Chemical Compatibility

- Fatty and oily substances often found in food processing

- Certain lubricants or greases used in facility maintenance

- Many mild chemicals, including some acidic and alkaline solutions

3. Benefits

- Cost Efficiency: BUNA-N is often more budget-friendly than other elastomers.

- Good Sealing Properties: Offers reliable sealing against a range of mild to moderate chemicals and substances.

- Oil Resistance: Particularly useful where fats or oils are prominent in the production line.

4. Drawbacks

- Temperature Limitations: BUNA-N may degrade under higher temperatures or with exposure to steam.

- Chemical Sensitivity: It is not as chemically resistant as some other elastomers, making it unsuitable for certain aggressive chemicals or solvents.

EPDM (Ethylene Propylene Diene Monomer) Seats

1. Primary Characteristics

- Exceptional resistance to heat and steam

- Widely used in Clean In Place (CIP) cycles in food and pharmaceutical facilities

- Good overall chemical resistance to a broad spectrum of fluids

2. Common Chemical Compatibility

- Hot water, steam, and many cleaning agents used in CIP processes

- Diluted acids, alkali solutions, and some oxidizing chemicals

- Ideal for certain beverage applications where frequent high-temperature washdowns are common

3. Benefits

- High Temperature Resistance: Excellent for processes requiring repeated exposure to heat or steam.

- Strong Chemical Compatibility: Suited for many aggressive cleaning solutions used in sanitary processing.

- Durability: EPDM tends to have a long service life when properly used and maintained.

4. Drawbacks

- Not Suitable for Oils/Petroleum: EPDM degrades when exposed to certain fats and petroleum-based products.

- Higher Cost: While still cost-effective, EPDM is generally more expensive than BUNA-N.

Which Seat Material Is Right for You?

Choosing between BUNA-N and EPDM largely depends on the specific process conditions in your facility. Consider these guiding questions:

- Do you regularly process oils or fatty products?

If yes, BUNA-N may provide better compatibility. - Does your process involve frequent high-temperature cleaning or steam exposure?

If yes, EPDM is more likely to withstand these conditions. - What types of chemicals are you introducing into the process?

Evaluate whether the seat material offers the required compatibility for cleaning agents, solvents, or any other chemicals in use. - Are you looking for cost savings or performance for a specific environment?

BUNA-N is generally the more cost-effective option, while EPDM can offer longer service life under higher temperatures and aggressive chemical conditions, potentially offsetting the higher initial cost.

Conclusion & Next Steps

Selecting the right butterfly valves seat is a critical decision that impacts product integrity, operational efficiency, and overall facility costs. Whether you decide on BUNA-N or EPDM, understanding each material’s strengths and weaknesses will guide you to the most suitable valve for your specific application. Shop all sanitary valve and general purpose valve offerings.