Tri-Clamp Gaskets – Type 1 Standard (40MP)

- Available in Buna, EPDM, Teflon®, Viton®, and Silicone

- Sizes from 1/2″ up to 12″

- Creates a leak-proof seal between tri-clamp flanges

- We also offer Flanged Tri-Clamp Gaskets

- Compound Selection Guide

- Temperature & Usage Guide

- Sizing Guide

- FDA / USP Class VI Tested (Select sizes & material)

Sanitary tri-clamp gaskets are used to make a secure, leak-proof connection between clamp fittings.

A variety of materials are available for selection depending upon medium used inline processing. Gaskets range in size from 1/2 inch to 12 inches.

If you would like a copy of a gaskets certificate, please ask for them at the time of order. Certificates are specific per lot of gaskets. Much like a heat number for fittings, gaskets have what is called a lot number. We don’t log these numbers at the time of order but we do include them on the packaging if you need the certificate after receiving them.

Please see Compound Selection Guide for compatibility information.

| Size (Tube OD) | Material | |||

|---|---|---|---|---|

| Buna | EPDM | Teflon® | Viton® | |

| 1/2" | 40MPU-1/2 | 42MPE-1/2 | 42MPG-1/2 | 42MPSFY-1/2 |

| 3/4" | 40MPU-3/4 | 42MPE-3/4 | 42MPG-3/4 | 42MPSFY-3/4 |

| 1" | 40MPU-1 | 40MPE-1 | 42MPG-1 | 42MPSFY-1 |

| 1 1/2" | 40MPU-1.5 | 40MPE-1.5 | 42MPG-1.5 | 42MPSFY-1.5 |

| 2" | 40MPU-2 | 40MPE-2 | 42MPG-2 | 42MPSFY-2 |

| 2 1/2" | 40MPU-2.5 | 40MPE-2.5 | 42MPG-2.5 | 42MPSFY-2.5 |

| 3" | 40MPU-3 | 40MPE-3 | 42MPG-3 | 42MPSFY-3 |

| 4" | 40MPU-4 | 40MPE-4 | 42MPG-4 | 42MPSFY-4 |

| 6" | 40MPU-6 | 40MPE-6 | 42MPG-6 | 42MPSFY-6 |

| 8" | 40MPU-8 | 40MPE-8 | N/A | N/A |

| 10" | 40MPU-10 | 40MPE-10 | N/A | N/A |

| 12" | 40MPU-12 | 40MPE-12 | N/A | N/A |

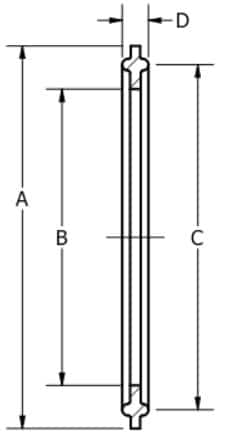

Tri-Clamp Gasket Sizes & Dimensions

| Sanitary Size | A | B | C | D |

| 1/2" | .875 | .4375 | NA | |

| 3/4" | .875 | .6250 | NA | |

| 1" | 1.984" | .900" | 1.718" | 0.203" |

| 1 1/2" | 1.984" | 1.400" | 1.718" | 0.203" |

| 2" | 2.515" | 1.900" | 2.218" | 0.203" |

| 2 1/2" | 3.050" | 2.400" | 2.781" | 0.203" |

| 3" | 3.579" | 2.900" | 3.281" | 0.203" |

| 4" | 4.682" | 3.869" | 4.344" | 0.203" |

| 6" | 6.570" | 5.813" | 6.176" | 0.203" |

| 8" | 8.570" | 7.813" | 8.165" | 0.238" |

| 10" | 10.570" | 9.813" | 10.156" | 0.238" |

| 12" | 12.570" | 11.813" | 12.151" | 0.238" |

Tri-Clamp Gasket Comparison Guide

| Gasket | Temperature Range | Recommended Usage | Not Recommended | Industry | Certification Approval |

|---|---|---|---|---|---|

| Buna (Nitrile) | Standard: -35°F to 250°F (-37°C to 121°C) | Water, Oils, Fuels | Ketones, Strong Acids, Sunlight, Ozone, Weathering | Food & Beverage | FDA Approved |

| EPDM (Ethylene Propylene) | Standard: -65°F to 300°F (-54°C to 149°C) | Sunlight, Weathering, Hot Water, Steam, Select Acids/Bases, Alcohols | Oils, Fuels | Bio-Pharmaceutical, Food & Beverage, Drinking Water | USP Class VI Tested |

| PTFE (Teflon®) | Standard: -100°F to 450°F (-74°C to 232°C) | Chemical, Heat, Pressure Applications | Stretching, Elasticity | Chemical Processing | USP Class VI Tested |

| FKM (Viton®) | Standard: -15°F to 437°F (-26°C to 222°C) | Vacuum, Most Acids / Chemicals, Oils, Fuels | Ketones, Ammonia, Hot Water / Steam | Chemical Processing | USP Class VI Tested |

| Silicone | Standard: -65°F to 450°F (-53°C to 232°C) | Food processing machinery and industrial oven seals in the food industry. In the medical industry, they are used for medical and healthcare equipment. | Ammonium Nitrite, Barium Sulfate, Milk | Benzene, Butane, Freon | USP Class VI Tested |

How to Measure Tri-Clamp Fittings

Tri-Clamp Fittings and Gasket Sizing Guide

| Sanitary Size |

Flange OD (?) |

Tube ID (?) |

Tube OD (?) |

|---|---|---|---|

| 1/2″ | 0.984 | 0.370 | 0.500 |

| 3/4″ | 0.984 | 0.620 | 0.750 |

| 1″ | 1.984 | 0.870 | 1.000 |

| 1 1/2″ | 1.984 | 1.370 | 1.500 |

| 2″ | 2.516 | 1.870 | 2.000 |

| 2 1/2″ | 3.047 | 2.370 | 2.500 |

| 3″ | 3.579 | 2.870 | 3.000 |

| 4″ | 4.682 | 3.834 | 4.000 |

| 6″ | 6.562 | 5.782 | 6.000 |

| 8″ | 8.602 | 7.782 | 8.000 |

| 10″ | 10.570 | 9.782 | 10.000 |

| 12″ | 12.570 | 11.760 | 12.000 |

Looking for even more information on Tri-Clamp fittings?

We have everything you need. Read "The Ultimate Guide to Tri-Clamp Fittings"

Additional information

Line Drawings

| SKU | Description | Line Drawing |

|---|---|---|

| 40MOE-5 | 5″ Black EPDM Class VI Tri-Clamp Gasket |

|

| 40MOE-6-VI | 6″ Black EPDM Tri-Clamp Gasket |

|

| 40MOE-8 | 8″ Black EPDM Tri-Clamp Gasket |

|

| 40MOEW-5 | 5″ White EPDM Tri-Clamp Gasket |

|

| 40MOEW-6 | 6″ White EPDM Tri-Clamp Gasket |

|

| 40MOFE-10 | 10″ Black EPDM Tri-Clamp Gasket |

|

| 40MOFE-12 | 12″ Black EPDM Tri-Clamp Gasket |

|

| 40MOFSFY-10 | 10″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MOFU-10 | 10″ Black Buna Tri-Clamp Gasket |

|

| 40MOG-10 | 10″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MOG-12 | 12″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MOG-5 | 5″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MOG-6 | 6″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MOG-8 | 8″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MOGBT-10 | 10″ Blue PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MOGBT-6 | 6″ Blue PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MOGBT-8 | 8″ Blue PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MOSFY-12 | 12″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MOSFY-8 | 8″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MOU-5 | 5″ Black Buna Tri-Clamp Gasket |

|

| 40MOU-6 | 6″ Black Buna Tri-Clamp Gasket |

|

| 40MOU-8 | 8″ Black Buna Tri-Clamp Gasket |

|

| 40MOUW-5 | 5″ White Buna Tri-Clamp Gasket |

|

| 40MOUW-6 | 6″ White Buna Tri-Clamp Gasket |

|

| 40MOUW-8 | 8″ White Buna Tri-Clamp Gasket |

|

| 40MOWSFY-6 | 6″ White FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MOX-5 | 5″ White Silicone Tri-Clamp Gasket |

|

| 40MOX-6 | 6″ White Silicone Tri-Clamp Gasket |

|

| 40MP-12-BUNA | 12″ Black Buna Tri-Clamp Gasket |

|

| 40MPE-1-VI | 1″ Black EPDM Tri-Clamp Gasket |

|

| 40MPE-1.5-VI | 1 1/2″ Black EPDM Tri-Clamp Gasket |

|

| 40MPE-2-VI | 2″ Black EPDM Tri-Clamp Gasket |

|

| 40MPE-2.5-VI | 2 1/2″ Black EPDM Tri-Clamp Gasket |

|

| 40MPE-3-VI | 3″ Black EPDM Tri-Clamp Gasket |

|

| 40MPE-4-VI | 4″ Black EPDM Tri-Clamp Gasket |

|

| 40MPER-1.5 | 1 1/2″ Red EPDM Tri-Clamp Gasket |

|

| 40MPER-2 | 2″ Red EPDM Tri-Clamp Gasket |

|

| 40MPER-2.5 | 2 1/2″ Red EPDM Tri-Clamp Gasket |

|

| 40MPER-3 | 3″ Red EPDM Tri-Clamp Gasket |

|

| 40MPER-4 | 4″ Red EPDM Tri-Clamp Gasket |

|

| 40MPEW-1 | 1″ White EPDM (Peroxide Cured) Tri-Clamp Gasket |

|

| 40MPEW-1.5 | 1 1/2″ White EPDM (Peroxide Cured) Tri-Clamp Gasket |

|

| 40MPEW-2 | 2″ White EPDM (Peroxide Cured) Tri-Clamp Gasket |

|

| 40MPEW-2.5 | 2 1/2″ White EPDM (Peroxide Cured) Tri-Clamp Gasket |

|

| 40MPEW-3 | 3″ White EPDM (Peroxide Cured) Tri-Clamp Gasket |

|

| 40MPEW-4 | 4″ White EPDM (Peroxide Cured) Tri-Clamp Gasket |

|

| 40MPG-1 | 1″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPG-1.5 | 1 1/2″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPG-2 | 2″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPG-2.5 | 2 1/2″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPG-3 | 3″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPG-4 | 4″ White PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPGBT-1 | 1″ Blue PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPGBT-1.5 | 1 1/2″ Blue PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPGBT-2 | 2″ Blue PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPGBT-2.5 | 2 1/2″ Blue PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPGBT-3 | 3″ Blue PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPGBT-4 | 4″ Blue PTFE (Teflon) Tri-Clamp Gasket |

|

| 40MPSFY-1 | 1″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFY-1.5 | 1 1/2″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFY-2 | 2″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFY-2.5 | 2 1/2″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFY-3 | 3″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFY-4 | 4″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFY-6 | 6″ Black FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYB-1 | 1″ Blue FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYB-1.5 | 1 1/2″ Blue FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYB-2 | 2″ Blue FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYB-2.5 | 2 1/2″ Blue FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYB-3 | 3″ Blue FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYB-4 | 4″ Blue FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYG-1 | 1″ Green FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYG-1.5 | 1 1/2″ Green FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYG-2 | 2″ Green FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYG-2.5 | 2 1/2″ Green FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYG-3 | 3″ Green FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYG-4 | 4″ Green FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYR-1.5 | 1 1/2″ Red FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYR-2 | 2″ Red FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYR-2.5 | 2 1/2″ Red FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYR-3 | 3″ Red FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYR-4 | 4″ Red FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYY-1 | 1″ Yellow FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYY-1.5 | 1 1/2″ Yellow FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYY-2 | 2″ Yellow FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYY-2.5 | 2 1/2″ Yellow FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYY-3 | 3″ Yellow FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPSFYY-4 | 4″ Yellow FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPU-1 | 1″ Black Buna Tri-Clamp Gasket |

|

| 40MPU-1.5 | 1 1/2″ Black Buna Tri-Clamp Gasket |

|

| 40MPU-2 | 2″ Black Buna Tri-Clamp Gasket |

|

| 40MPU-2.5 | 2 1/2″ Black Buna Tri-Clamp Gasket |

|

| 40MPU-3 | 3″ Black Buna Tri-Clamp Gasket |

|

| 40MPU-4 | 4″ Black Buna Tri-Clamp Gasket |

|

| 40MPUB-1 | 1″ Blue Buna Tri-Clamp Gasket |

|

| 40MPUB-1.5 | 1 1/2″ Blue Buna Tri-Clamp Gasket |

|

| 40MPUB-2 | 2″ Blue Buna Tri-Clamp Gasket |

|

| 40MPUB-2.5 | 2 1/2″ Blue Buna Tri-Clamp Gasket |

|

| 40MPUB-3 | 3″ Blue Buna Tri-Clamp Gasket |

|

| 40MPUB-4 | 4″ Blue Buna Tri-Clamp Gasket |

|

| 40MPUG-1 | 1″ Green Buna Tri-Clamp Gasket |

|

| 40MPUG-1.5 | 1 1/2″ Green Buna Tri-Clamp Gasket |

|

| 40MPUG-2 | 2″ Green Buna Tri-Clamp Gasket |

|

| 40MPUG-2.5 | 2 1/2″ Green Buna Tri-Clamp Gasket |

|

| 40MPUG-3 | 3″ Green Buna Tri-Clamp Gasket |

|

| 40MPUG-4 | 4″ Green Buna Tri-Clamp Gasket |

|

| 40MPUO-1.5 | 1 1/2″ Orange Buna Tri-Clamp Gasket |

|

| 40MPUO-2 | 2″ Orange Buna Tri-Clamp Gasket |

|

| 40MPUO-3 | 3″ Orange Buna Tri-Clamp Gasket |

|

| 40MPUO-4 | 4″ Orange Buna Tri-Clamp Gasket |

|

| 40MPUPK-1 | 1″ Pink Buna Tri-Clamp Gasket |

|

| 40MPUPK-1.5 | 1 1/2″ Pink Buna Tri-Clamp Gasket |

|

| 40MPUPK-2 | 2″ Pink Buna Tri-Clamp Gasket |

|

| 40MPUPK-2.5 | 2 1/2″ Pink Buna Tri-Clamp Gasket |

|

| 40MPUPK-3 | 3″ Pink Buna Tri-Clamp Gasket |

|

| 40MPUPK-4 | 4″ Pink Buna Tri-Clamp Gasket |

|

| 40MPUPURPLE-1 | 1″ Purple Buna Tri-Clamp Gasket |

|

| 40MPUPURPLE-1.5 | 1 1/2″ Purple Buna Tri-Clamp Gasket |

|

| 40MPUPURPLE-2 | 2″ Purple Buna Tri-Clamp Gasket |

|

| 40MPUPURPLE-2.5 | 2 1/2″ Purple Buna Tri-Clamp Gasket |

|

| 40MPUPURPLE-3 | 3″ Purple Buna Tri-Clamp Gasket |

|

| 40MPUPURPLE-4 | 4″ Purple Buna Tri-Clamp Gasket |

|

| 40MPUR-1 | 1″ Red Buna Tri-Clamp Gasket |

|

| 40MPUR-1.5 | 1.5″ Red Buna Tri-Clamp Gasket |

|

| 40MPUR-2 | 2″ Red Buna Tri-Clamp Gasket |

|

| 40MPUR-2.5 | 2 1/2″ Red Buna Tri-Clamp Gasket |

|

| 40MPUR-3 | 3″ Red Buna Tri-Clamp Gasket |

|

| 40MPUR-4 | 4″ Red Buna Tri-Clamp Gasket |

|

| 40MPUW-1 | 1″ White Buna Tri-Clamp Gasket |

|

| 40MPUW-1.5 | 1 1/2″ White Buna Tri-Clamp Gasket |

|

| 40MPUW-2 | 2″ White Buna Tri-Clamp Gasket |

|

| 40MPUW-2.5 | 2 1/2″ White Buna Tri-Clamp Gasket |

|

| 40MPUW-3 | 3″ White Buna Tri-Clamp Gasket |

|

| 40MPUW-4 | 4″ White Buna Tri-Clamp Gasket |

|

| 40MPUY-1 | 1″ Yellow Buna Tri-Clamp Gasket |

|

| 40MPUY-1.5 | 1 1/2″ Yellow Buna Tri-Clamp Gasket |

|

| 40MPUY-2 | 2″ Yellow Buna Tri-Clamp Gasket |

|

| 40MPUY-2.5 | 2 1/2″ Yellow Buna Tri-Clamp Gasket |

|

| 40MPUY-3 | 3″ Yellow Buna Tri-Clamp Gasket |

|

| 40MPUY-4 | 4″ Yellow Buna Tri-Clamp Gasket |

|

| 40MPUY-6 | 6″ Yellow Buna Tri-Clamp Gasket |

|

| 40MPWSFY-1 | 1″ White FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPWSFY-1.5 | 1 1/2″ White FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPWSFY-2 | 2″ White FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPWSFY-2.5 | 2 1/2″ White FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPWSFY-3 | 3″ White FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPWSFY-4 | 4″ White FKM/SFY Viton Tri-Clamp Gasket |

|

| 40MPX-1 | 1″ White Silicone Tri-Clamp Gasket |

|

| 40MPX-1.5 | 1 1/2″ White Silicone Tri-Clamp Gasket |

|

| 40MPX-2 | 2″ White Silicone Tri-Clamp Gasket |

|

| 40MPX-2.5 | 2 1/2″ White Silicone Tri-Clamp Gasket |

|

| 40MPX-3 | 3″ White Silicone Tri-Clamp Gasket |

|

| 40MPX-4 | 4″ White Silicone Tri-Clamp Gasket |

|

| 40MPX-R-1.5 | 1 1/2″ Red Silicone Tri-Clamp Gasket |

|

| 40MPX-R-2 | 2″ Red Silicone Tri-Clamp Gasket |

|

| 40MPX-R-4 | 4″ Red Silicone Tri-Clamp Gasket |

|

| 40MPXB-2.5 | 2 1/2″ Blue Silicone Tri-Clamp Gasket |

|

| 42MPE-1/2 | 1/2″ Black EPDM Tri-Clamp Gasket |

Request Line Drawing |

| 42MPE-3/4 | 3/4″ Black EPDM Tri-Clamp Gasket |

Request Line Drawing |

| 42MPE-3/4-VI | 3/4″ Black EPDM Class VI Tri-Clamp Gasket |

|

| 42MPG-1/2 | 1/2″ White PTFE (Teflon) Tri-Clamp Gasket |

Request Line Drawing |

| 42MPG-3/4 | 3/4″ White PTFE (Teflon) Tri-Clamp Gasket |

Request Line Drawing |

| 42MPGBT-3/4 | 3/4″ Blue PTFE (Teflon) Tri-Clamp Gasket |

Request Line Drawing |

| 42MPSFY-1/2 | 1/2″ Black FKM/SFY Viton Tri-Clamp Gasket |

Request Line Drawing |

| 42MPSFY-3/4 | 3/4″ Black FKM/SFY Viton Tri-Clamp Gasket |

Request Line Drawing |

| 42MPU-1/2 | 1/2″ Black Buna Tri-Clamp Gasket |

Request Line Drawing |

| 42MPU-3/4 | 3/4″ Black Buna Tri-Clamp Gasket |

Request Line Drawing |

| 42MPUW-1/2 | 1/2″ White Buna Tri-Clamp Gasket |

Request Line Drawing |

| 42MPUW-3/4 | 3/4″ White Buna Tri-Clamp Gasket |

Request Line Drawing |

| 42MPWSFY-1/2 | 1/2″ White FKM/SFY Viton Tri-Clamp Gasket |

Request Line Drawing |

| 42MPWSFY-3/4 | 3/4″ White FKM/SFY Viton Tri-Clamp Gasket |

Request Line Drawing |

| 42MPX-1/2 | 1/2″ White SIlicone Tri-Clamp Gasket |

Request Line Drawing |

| 42MPX-3/4 | 3/4″ White Silicone Tri-Clamp Gasket |

Request Line Drawing |

-

Are the PTFE tri-clamp gaskets rated to full vacuum at 40 degree C using a High Pressure Tri-Clamp?

-

Q Are the PTFE tri-clamp gaskets rated to full vacuum at 40 degree C using a High Pressure Tri-Clamp?A

Unfortunately, none of the gaskets or fittings that we provide are rated for vacuum conditions.

I am working on a design that requires somewhat tight tolerance on positioning of a tri-clamp end cap. I have not found a good reference for recommended/expected gasket compression. This will be a 10” BUNA sanitary gasket, do you have any guidance you can share?

-

Q I am working on a design that requires somewhat tight tolerance on positioning of a tri-clamp end...... Read moreA I don't have additional guidance that I can provide other than overtightening the gaskets can cause them to warp and possibly leak. Tri-Clamp gasket connections should be hand tightened just beyond a range I would refer to as "snug". The gasket is able to do the job it was intended for, it really just needs to be held firmly in place by the clamp.

I would like to request a sample for this gasket_SKU: 40MP-1-VITON

-

Q I would like to request a sample for this gasket_SKU: 40MP-1-VITONA Sure, we can do that for you. I'll reach out to you for additional contact information.

Best material for high pressure, 750 psi and temperature, 200F?

-

Q Best material for high pressure, 750 psi and temperature, 200F?A At that temperature, you can utilize any of our gaskets. For that level of pressure, we recommend our double-pin high-pressure clamp.

Are there any animal origin materials used in your gaskets?

-

Q Are there any animal origin materials used in your gaskets?A Our gaskets are comprised of 100% synthetic materials.

What is the benefit of Tri-Clamp Envelope gaskets?

-

Q What is the benefit of Tri-Clamp Envelope gaskets?A The reason for choosing the Envelope Gasket is because Teflon, by itself, is kind of a rigid material. EPDM on the other hand is very flexible. This gasket is an EPDM gasket center with Teflon outside. It works great in environments where you need the durability to stand up to harsh chemicals that Teflon provides but the flexibility that EPDM offers.

These gaskets are class IV rated. What does class IV rating mean?

-

Q These gaskets are class IV rated. What does class IV rating mean?A Class IV gasket rating is a certificate stating that the material used within gaskets is not harmful to living things. While gasket material should not wind up in the manufacturer's final product if it did find its way to the consumer it would not be harmful to ingest.

Best gasket material for high proof ethanol?

-

Q Best gasket material for high proof ethanol?A We recommend EPDM gasket material for any alcohol process line implementations including ethyl alcohol.

I’ve noticed leaking at a couple of connection points. All tri-clamp fittings and gaskets are new. Clamps are tight. What can I do to eliminate the leakage?

-

Q I’ve noticed leaking at a couple of connection points. All tri-clamp fittings and gaskets are new...... Read moreA With regards to any leaking tri-clamp fittings, start by checking that the gasket is properly seated in the grooves. Depending upon the material of gasket, sometimes less flexible gaskets can bend/flex in a bad way if it's overtightened. I would check to make sure that you are not going about 1 full turn past "snug". Give these things a try and see if they help.

What is the country of origin for these gaskets?

-

Q What is the country of origin for these gaskets?A The country of origin for our tri-clamp gaskets is the United States. For your reference, the HTS code is 3926.90.4500.

Are the PTFE tri-clover gaskets FDA approved?

-

Q Are the PTFE tri-clover gaskets FDA approved?A Yes! Our tri-clamp gaskets are approved by the Food & Drug Administration for use in the production of food, beverage and pharmaceutical industries. We can supply a certificate stating as such upon demand. Additionally, these gaskets are also Class VI tested by USP to be in compliance with their testing criteria. We can also supply a certificate stating as such.