Your full-service supplier for

Sanitary Tubing, Spool Assemblies & Tube Hangers

When downtime isn’t an option, you need a sanitary parts supplier you can count on. Sanitary Fittings delivers with an extensive inventory of stainless steel sanitary tubing, tri-clamp spool assemblies, and hygienic tube hangers for the food, beverage, dairy, pharmaceutical, or biotech industries. Backed by knowledgeable customer service, fast same-day shipping, and custom fabrication capabilities, we provide hygienic reliability across industries.

And with hassle-free online ordering, getting the right sanitary tubing has never been easier.

Jump to a Product

Learn when to use tubing versus spools and how to correctly choose your mounting system

Why Choose Sanitary Fittings?

We’ve got the experience in the sanitary industry that sets us apart from most online distributers

Custom Fabrication Capabilities

Large Selection of Products and Inventory

Same Day Shipping on Most Orders

Exceptional Customer Service

What is Stainless Steel Sanitary Tubing?

Learn more about tubing, how it’s used, and what the different options mean

Our polished stainless steel sanitary tubing is manufactured in accordance with ASTM A270 standards and is offered in precut 80″ lengths, 20′ sticks, or by the case. This tubing is made from cold-rolled stainless steel strips, whose chemical elements are specially controlled to enhance weldability. The weld bead is cold-worked to a full finished condition, resulting in a virtually undetectable longitudinal weld. Bright annealing follows in a controlled atmosphere to preserve maximum structural integrity.

We also offer stainless steel biopharm (BPE) sanitary tubing with 20Ra SF1 or 15Ra SF4 electropolished finishes.

What are the benefits to using sanitary tubing?

- Seamless and smooth interior for optimal product flow

- Lower risk of leaks due to welded connections

- High durability under pressure and extreme conditions

- Aesthetically clean and professional finish

When should I use sanitary tubing?

Consider using sanitary tubing in the following scenarios:

- High-Purity Requirements:

When the manufacturing process demands a high degree of purity to meet industry standards and regulatory requirements. - Corrosive Environments:

In applications where resistance to corrosion is crucial, such as handling corrosive chemicals or operating in aggressive environments. - Critical Hygiene Conditions:

Processes that involve sensitive products, such as pharmaceuticals or biotechnological substances, where the risk of contamination must be minimized.

To learn more about sanitary tubing, read, “Sanitary Tubing in Manufacturing Processes“.

Who uses sanitary tubing in their facilities?

- Pharmaceuticals: Used in large-scale production facilities for sterile environments.

- Chemical Processing: Suitable for high-pressure or high-temperature systems.

- Dairy and Food Production: Ensures long-term reliability in fixed pipelines.

What are the ASTM A270 standards?

ASTM A270 is a set of standards developed by the American Society for Testing and Materials (ASTM) that specifically addresses the requirements for seamless and welded austenitic stainless steel sanitary tubing intended for use in dairy and food industry and having special surface finishes.

The standard encompasses various dimensions, mechanical properties, and surface finish requirements to ensure the tubes’ suitability for hygienic applications.

Read more about the key features of ASTM A270 and how they compare to other standards here, “Understanding the ASTM A270 Hygienic Tubing Standard“.

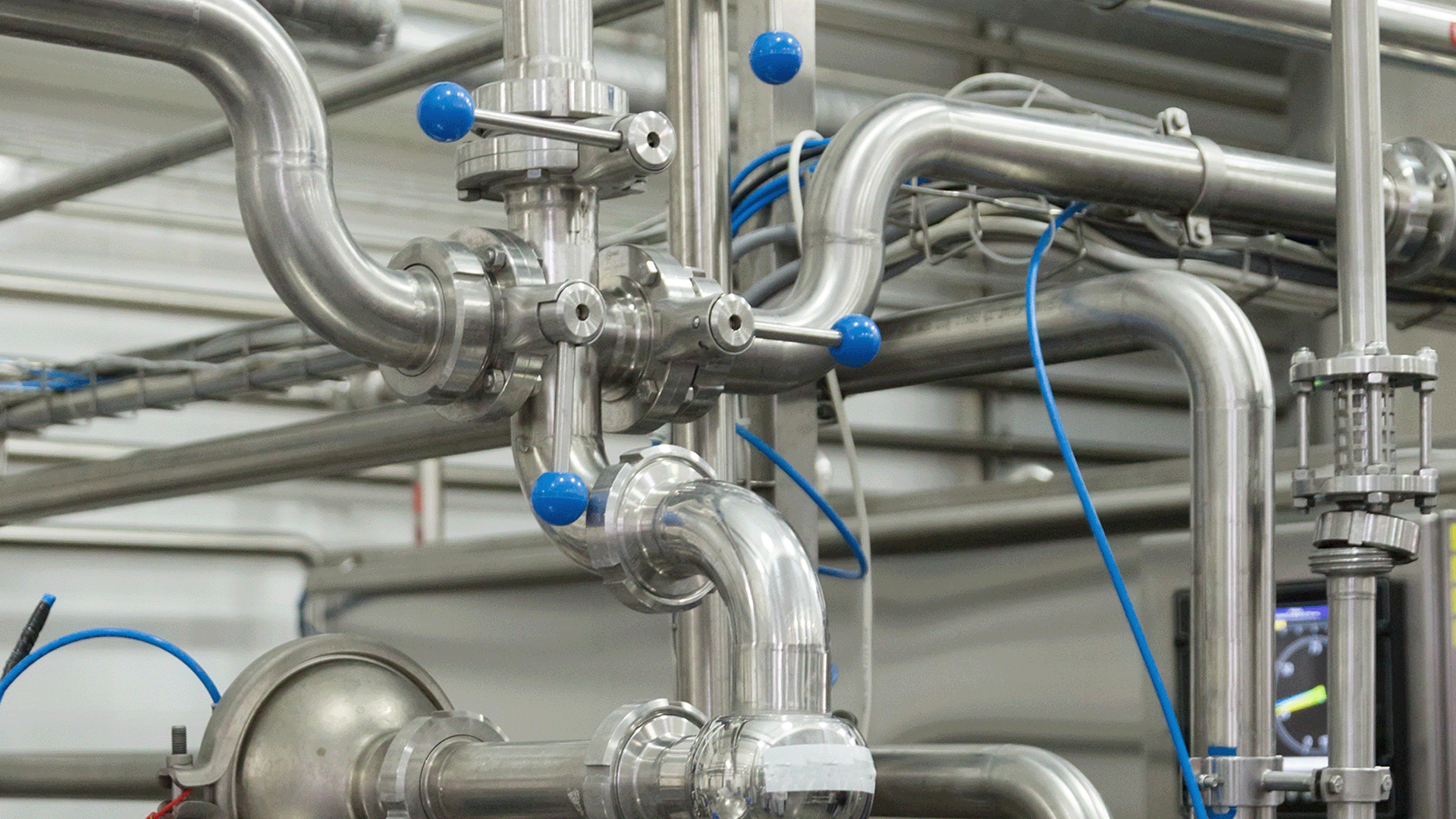

Fully-Customizable Tri-Clamp Spool Assemblies

Highly versatile Tri-Clamp ferrule connections

Tri-Clamp sanitary spool assemblies are similar to their weldable cousins (sanitary tubing), but come with the industry-standard Tri-Clamp ferrules. Our spools are manufactured to meet 3-A sanitary standards.

Instead of hunting around for the perfect fit, we make it easy to design the exact spool you need, with our spool customizer. Choose your alloy, ferrules, tube size, and length. All online!

We also offer Tri-Clamp biopharm (BPE) polished spool assemblies with 20Ra SF1 or 15Ra SF4 electropolished finishes.

What is the difference between spools and tubing?

- Design and Functionality:

- Tri-Clamp Spool Assemblies: These are pre-assembled sections of tubing fitted with tri-clamp ferrules on either end. They are designed for quick and easy connections, enabling modular system design and effortless disassembly for cleaning or replacement.

- Stainless Steel Sanitary Tubing: This refers to plain lengths of tubing without pre-attached fittings. It is often cut and welded into place, offering a seamless and permanent connection.

- Ease of Installation:

- Spool assemblies are ideal for systems requiring frequent disassembly or modifications, thanks to their tri-clamp connections.

- Sanitary tubing requires skilled labor for installation, as it often involves welding and polishing to ensure a smooth, sanitary finish.

- Flexibility:

- Spool assemblies offer more flexibility in reconfiguring process lines.

- Tubing provides a more rigid and permanent setup, suitable for fixed systems.

When should I use Tri-Clamp spool assemblies?

- Applications with Frequent Cleaning: The ease of disassembly makes them perfect for CIP (clean-in-place) or SIP (sterilize-in-place) systems.

- Processes Requiring Modular Systems: They allow for quick changes or upgrades to process lines.

- Small to Medium-Scale Operations: Ideal where processes change frequently or where there is a need to quickly replace components.

What are some industries that use spool assemblies?

- Food and Beverage: Used in brewing, dairy production, and bottling lines.

- Pharmaceuticals and Biotech: Ideal for systems with strict cleaning protocols.

- Cosmetics: Common in modular production systems requiring frequent product changes.

What are 3-A standards?

3-A Sanitary Standards were developed as a collaboration between various sectors of the sanitary equipment industry, including regulatory agencies, equipment manufacturers, and end-users. Their goal is to establish comprehensive benchmarks for sanitary design and construction. By meeting 3-A criteria, manufacturers demonstrate that their products are engineered to prevent contamination and promote cleanliness, ultimately safeguarding the integrity of food-grade products.

Read more about these standards here, “What are 3-A Sanitary Standards and How to Meet Them“.

Sanitary Tube Hangers

Specialized hangers for your sanitary tubing and spool assemblies

Often over-looked when designing or retrofitting a sanitary facility, these sanitary tube hangers are fixtures that secure stainless steel tubing, Tri-Clamp spool assemblies, and piping in place. These tools ensure minimal vibration and movement of you tubing and spools.

Unlike conventional industrial clamps, these hangers are designed with smooth, crevice-free surfaces to reduce the likelihood of bacterial growth and contamination and are also easy to clean and sanitize.

What are the benefits to using tube hangers?

- Structural stability: Hangers support the weight of your tubing and their contents, shifting the load from the pipe itself to the support structure. This prevents sagging, stress, and buckling, which could lead to ruptures.

- Vibration and noise reduction: Many hangers are designed to isolate tubes from structural vibrations, which can reduce noise and create a more comfortable environment.

- Protection from damage: By keeping your tubing secure, hangers prevent them from scraping against surfaces or becoming dislodged, which protects them from physical damage and prolongs their lifespan.

- Improved system performance: By reducing stress and ensuring proper positioning, hangers help maintain the flow of liquids and the overall efficiency of the system.

- Safety enhancement: Proper support minimizes the risk of component failure and accidents caused by damaged or dislodged tubes, contributing to a safer working environment.

Who uses sanitary tube hangers?

- Food and Beverage Production: Breweries, dairies, and food processing plants rely on hygienic hangers to safeguard

the quality of their products and uphold strict sanitation standards. - Biopharmaceutical: Research labs, pharmaceutical production, and other life science applications depend

on sanitary hangers to maintain sterile conditions and avoid cross-contamination. - Personal Care and Cosmetics: Facilities requiring consistent cleanliness in product formulation also turn

to tube hangers for reliable, hygienic support.

How do I decide the right hangers for me?

Selecting the best sanitary hanger can be broken down into a few key considerations:

- Material Compatibility – Stainless steel is the go-to choice for most hygienic hanger applications due to its corrosion resistance and ease of cleaning. However, plastic or composite inserts might be used to reduce noise, vibration, or temperature transfer.

- Size and Load Requirements – Confirm that the hanger matches the diameter of your tubing and can support the total load, including the weight of the fluid in the pipe. Too small a hanger could lead to stress or damage, while an overly large hanger may not provide the necessary stability.

- Mounting Method – Some applications require wall-mounted hangers, while others might use ceiling or floor mounts. A well-chosen mounting method ensures easy access for cleaning and maintenance.

- Compliance and Regulatory Standards – Industries with stringent requirements, such as pharmaceutical or biotech, may necessitate certificates or third-party validation for sanitary hangers. Make sure your chosen product meets those regulatory standards.

Read our guide, “Sanitary Tube Hangers: A Guide to Choosing the Right Hanger“.

Shop Our Popular Product Categories

We’ve got everything you need to maintain, optimize, or repair your facility

3-A Stainless Fittings

We offer both 304 and 316L stainless steel alloy in sizes from 1” to 12”. Manufactured in accordance with 3A standards, these items are precision engineered to be utilized in the most demanding environments.

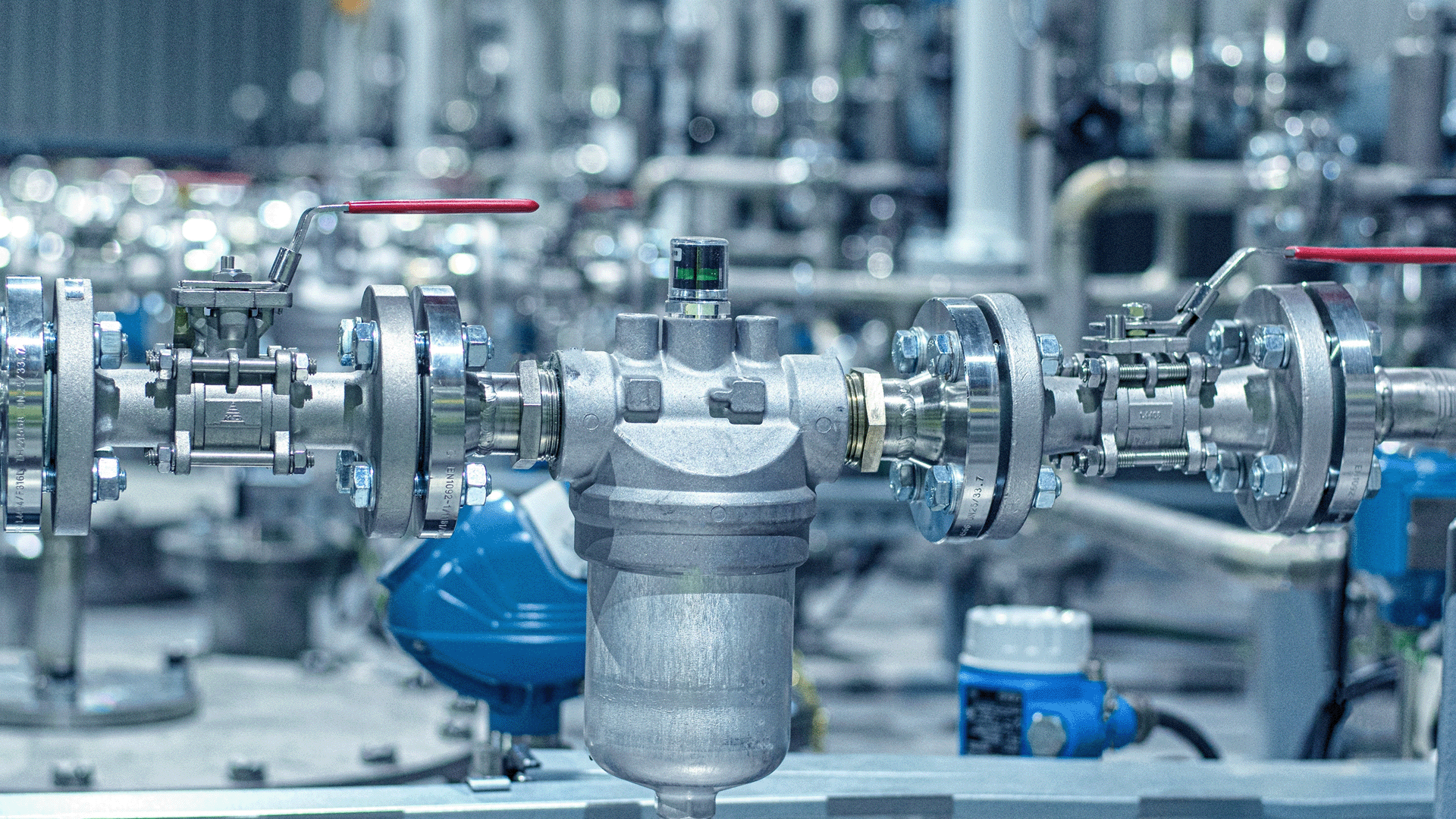

Stainless Steel Valves

NPT, Tri-Clamp, DIN, and more stainless steel valve styles that are designed to meet strict hygiene standards, including ball valves for straightforward on/off control, butterfly valves that pivot a disc for throttling or shutoff, and check valves that allow fluid to flow in one direction and prevent backflow.

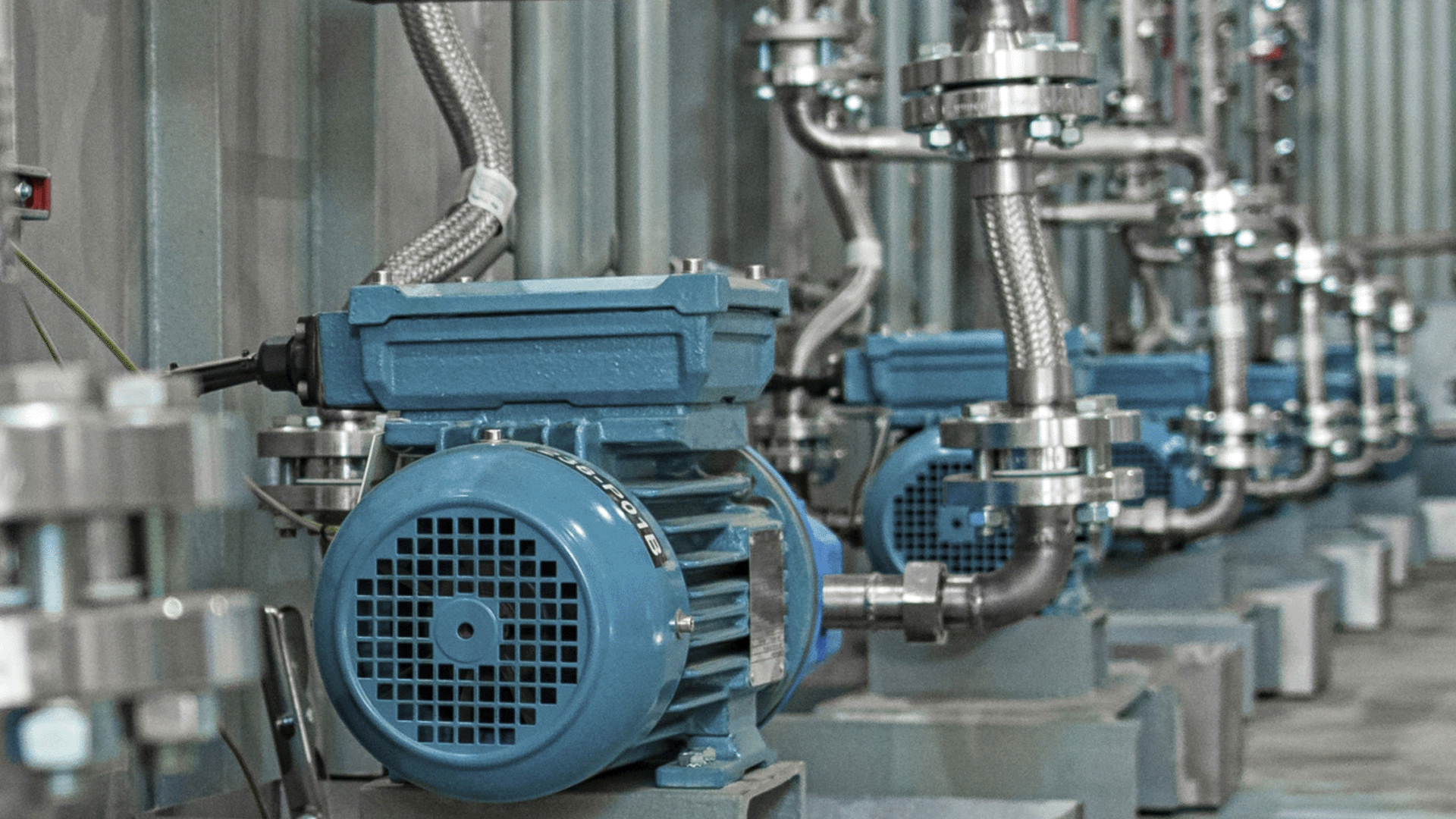

Centrifugal Pumps

Sanitary centrifugal pumps are ideal for use in most process applications in a wide range of sanitary process industries. TOP-FLO® pumps are suitable for use in CIP (clean-in-place) installations.

Frequently Asked Questions

Common questions about our products and services

How do spool assemblies reduce install time?

Pre-fabrication replaces on-site welding and polishing for Tri-clamp spools. Your stainless steel Tri-Clamp spools arrive ready to fit, enabling modular builds and faster changeouts.

Do I need a spool assembly or tubing?

When it comes to designing and optimizing sanitary process systems, selecting the right components can make all the difference. Two commonly used sanitary tubing options are tri-clamp spool assemblies and stainless steel sanitary tubing. While these products share some similarities, they serve different purposes depending on the requirements of your process line.

To see how spools and tubes are similar, different, and what industries commonly use each, read, “Deciding Between Spool Assemblies and Sanitary Tubing“.

Do you honor tax exempt certificates?

Yes! Please create an account with us to upload your documents directly to your profile. If you don’t have an account, you can submit your tax exempt certificate to sales@sanitaryfittings.us so we can get it on file. Once uploaded, you’ll be able to checkout online without paying taxes.

Do you offer lines of credit?

Yes. We offer qualified buyers standard terms of 2/10 NET 30. Please work with our sales team if you would like different terms.

Please contact sales@sanitaryfittings.us to request an application.

Can I use my own shipping account for my order?

Absolutely. Please send your account number and carrier preference to us before you order. We’ll switch over to your account. We currently work with UPS, FedEx, and DHL.

What's the difference between 32Ra, 20Ra, and 15Ra?

Here are some of the differences between different surface finishes:

1. 32 Ra (Roughness Average 32):

– This is a relatively standard surface finish and is considered suitable for many sanitary applications.

– It provides a reasonably smooth surface that is easy to clean and maintain.

– While it may not be the highest level of finish available, it is cost-effective and suitable for applications where extreme smoothness is not critical.

2. 20 Ra (Roughness Average 20):

– A 20 Ra surface finish is smoother than 32 Ra and is often preferred in applications where a higher level of cleanliness and hygiene is required.

– It offers improved resistance to bacterial adhesion and makes cleaning more effective.

– This finish is commonly used in industries like pharmaceuticals and food processing.

3. 15 Ra (Roughness Average 15):

– 15 Ra is an even smoother surface finish, and it is considered high-quality for sanitary applications.

– It provides excellent resistance to bacterial growth and is suitable for applications where the highest level of cleanliness and hygiene is essential.

– Industries such as biotechnology, semiconductor manufacturing, and ultra-pure water systems often require this level of surface finish to ensure product quality and purity.

Read more, “Sanitary Fittings and Surface Finish: Roughness Average Explained“.

Do tube hangers really make a difference?

Simply put, yes, they can. Some of the most important highlights are below:

- Structural stability: Hangers support the weight of your tubing and their contents, shifting the load from the pipe itself to the support structure. This prevents sagging, stress, and buckling, which could lead to ruptures.

- Vibration and noise reduction: Many hangers are designed to isolate tubes from structural vibrations, which can reduce noise and create a more comfortable environment.

- Protection from damage: By keeping your tubing secure, hangers prevent them from scraping against surfaces or becoming dislodged, which protects them from physical damage and prolongs their lifespan.

- Improved system performance: By reducing stress and ensuring proper positioning, hangers help maintain the flow of liquids and the overall efficiency of the system.

- Safety enhancement: Proper support minimizes the risk of component failure and accidents caused by damaged or dislodged tubes, contributing to a safer working environment.

Need help picking the correct sanitary tube hanger for your facility? Read our guide, “Sanitary Tube Hangers: A Guide to Choosing the Right Hanger“.

How do you ensure I get quality products and not cheap knockoffs?

As a distributor of stainless steel sanitary fittings, we’ve partnered solely with manufacturers capable of delivering the very best products on the market.

In most cases, our suppliers are ISO 9001 Certified, meaning they not only talk the talk, but walk the walk as well.

You can always rest assured that the parts we provide not only meet, but exceed your expectations for excellence. Read more about our quality inspection process.

Do you offer Material Test Reports (MTRs) for your products?

Material Test Reports (MTRs) come standard with all 316L stainless steel products.

We can provide MTRs for 304 products but we ask that you request these ahead of time. There may be additional fees for 304 MTRs because they are not recorded automatically.

What are 3-A standards?

3-A Sanitary Standards were developed as a collaboration between various sectors of the sanitary equipment industry, including regulatory agencies, equipment manufacturers, and end-users. Their goal is to establish comprehensive benchmarks for sanitary design and construction. By meeting 3-A criteria, manufacturers demonstrate that their products are engineered to prevent contamination and promote cleanliness, ultimately safeguarding the integrity of food-grade products.

Read more about, “3A Sanitary Standards and How to Meet Them“.

Related Blog Posts

Information on sanitary spools, tubing, and guides on how to find the right products for your facility

Sanitary Tube Hangers: A Guide to Choosing the Right Hanger

Sanitary tube hangers, sometimes referred to as hygienic tube hangers or pipe hangers, are critical components in maintaining clean, safe, and efficient...

Deciding Between Spool Assemblies and Sanitary Tubing

When it comes to designing and optimizing sanitary process systems, selecting the right components can make all the difference. Two commonly used sanitary...

Understanding Good Manufacturing Practices (GMP) in Sanitary Production

In highly regulated industries like food, beverage, and pharmaceutical production, maintaining quality and consistency is non-negotiable. One of the...

For more information on this topic and more, visit our blog