The Benefits of Tri-Clamp Butterfly Valves in Your Brewing System

Brew day is over.

Your ale, porter, or lager is happily resting (or is that working?) in the fermenter. You won’t be disturbing its peace for another 2 weeks. And now? It’s time to clean up and put everything back in order.

You’re a smart homebrewer, and you’ve used as many tri-clamp fittings in your brewing setup as possible. Release the clamp, give a tug, and the tubing pulls away, the spools come apart, the valves are separated.

But then comes the cleaning. And all those lovely ball valves you’ve used to control flow and keep things moving from tun to kettle to tun and back again have to be taken apart once they’re off the system.

Sure, tri-clamp ball valves are more sanitary than NPT (National Pipe Threads) ones. Yes, they are easier to set up and remove. But they do catch their share of “gunk”, especially when pushing trub or yeast through them.

Each one of those tri-clamp ball valves has bolts. Sometimes as many as four. Bolts that require unthreading and rethreading to take them apart.

And that really slows down the cleaning process at the end of a long day when all you want to do is kick back with a cold one.

What’s a brew guy (or gal) to do?

Here’s a bit of advice from us: Transition your system as much as possible to tri-clamp butterfly valves.

Why a tri-clamp butterfly valve? That’s what we’re going to talk about today. When you’re done, you’ll know all the ins and outs, ups and downs, the good, the bad, and yes, even the ugly, of using tri-clamp butterfly valves in your homebrew setup.

Here’s what we’ve got for you today:

A (Very) Brief Overview of Tri-Clamp Fittings

The Two Types of Tri-Clamp Butterfly Valve

Where and When to Use Tri-Clamp Butterfly Valves in Your Homebrew Setup

How We Can Help With Your Homebrewing Needs

Ready? Let’s get started.

A (Very) Brief Overview of Tri-Clamp Fittings

Did you know that tri-clamp fittings are sort of like ordering a coke with your lunch, and then happily drinking a root beer and not a Coca-Cola?

There was once a guy who invented the tri-clover fitting. He trademarked and branded Tri-Clover as a name for his fittings. Tri-clover fittings became very popular. Other guys started making generic tri-clover fittings of their very own.

But they couldn’t call them tri-clover anything, because that name belonged to the first guy and he wasn’t going to share it. And what eventually happened was that their name, tri-clamp, became the name most commonly used for all fittings of that style.

You’ll still find some guys who sell or discuss “tri-clover” fittings, true. But just like a “coke” can be any type of soda for many people, a tri-clamp can be any fitting that is basically two parts with a gasket held tightly between them by a clamp.

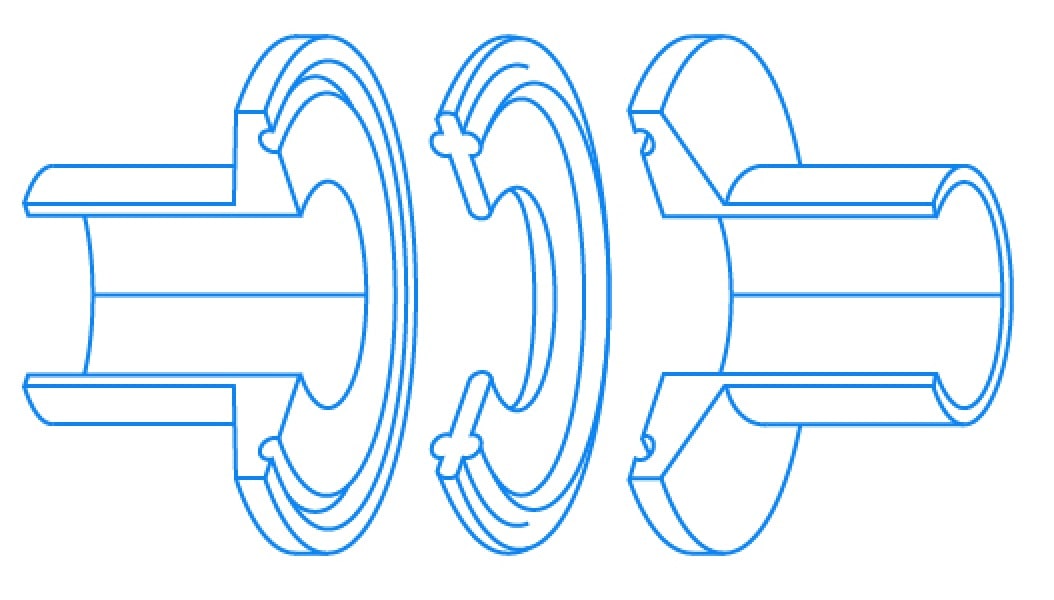

Here’s a schematic drawing of one, without the clamp:

All our tri-clamp fittings are made from either 316L or 304 stainless steel. This makes them suitable for the food and beverage industry, including your homebrewing setup. Some of our manufacturers carry the 3A certification, indicating the highest quality of sanitary fittings.

Sanitary food-grade stainless steel is easy to clean, corrosion-resistant, and generally considered best for the health of both your brew and you, the brewer, as long as you maintain its sanitary condition with proper cleaning and sanitizing.

You will find our Ultimate Guide to Tri-Clamp Fittings has everything you ever wanted to know, in case you want to know more.

The Two Types of Tri-Clamp Butterfly Valve

There are two types of tri-clamp butterfly valves available to the homebrewer. Both work in essentially the same way and have the same inner valve workings. The difference is in the handle and how it works.

The “butterfly” in a tri-clamp butterfly valve of either type is a flat metal disc mounted on a rod attached to the handle.

The butterfly valve is fully open or “on” when the handle is turned and the disc is rotated a quarter turn. The valve is fully closed or “off” when the handle is turned so the disc is blocking the flow.

Our tri-clamp butterfly valve allows for flow control by locking the disc in several positions.

The disc seals against a “seat” or inner seal, typically made of EDPM or silicone.

Now let’s look at each type of butterfly valve in detail.

The Pull Handle Tri-Clamp Butterfly Valve

When you don’t need quite as much process line flow, the pull handle butterfly valve should do the trick. Specifications of the pull handle tri-clamp butterfly valve include:

- Constructed of 316L food grade stainless steel

- Pull handle with four locking positions

- Operating temperatures of 15F to 200F

- Comes in a full range of sizes, from 1in to 4in tube OD

- Seat (inner seal) material is EPDM (also available in Viton)

- Maximum pressure is 140PSI

The Trigger Handle Tri-Clamp Butterfly Valve

When a bit more finesse of line flow is called for, the trigger handle tri-clamp butterfly valve may be a better choice. It’s specs include:

- Constructed of both 316L and 304 stainless steel, with a plastic trigger handle

- Trigger handle with 12 locking positions

- Maximum operating temp of 266F

- Comes in a full range of sizes from 1″ to 4″

- Seat (inner seal) material options include silicone, EPDM, and Viton

- Maximum pressure is 145PSI

To operate the pull trigger handle butterfly valve, you simply squeeze the trigger and then rotate the handle.

While it’s difficult to accidentally turn a pull handle valve, it’s not impossible, and some homebrewers prefer the added peace of mind the trigger handle offers.

Where and When to Use Tri-Clamp Butterfly Valves in Your Homebrew Setup

The long and the short of it is that all your tri-clamp butterfly valves will still need cleaning and maintenance. You may still have to periodically take them apart and deal with the same four bolts as a ball valve.

The good news is that using either type of tri-clamp butterfly valve on the hot side of your setup eliminates the need for all that cleaning.

Many guys simply open the tri-clamp butterfly valve after removing it and dump it in the PBW to soak alongside other fittings and tubings. The fact that a butterfly valve is less likely to catch gunk like a ball valve does makes them feel safer in not disassembling it each time.

They only periodically take their butterfly valves apart and check for gunk as well as seat wear. Replacement seats are available, so when a valve seat does show signs of wear, the valve itself isn’t done for.

Tri-clamp butterfly valves, especially pull trigger handled valves, are quite popular with the BIAB crowd, as you only need that one valve for flow control, and you want to ensure that it is reliable, long-lasting, high quality, sanitary, and easy to keep that way.

How We Can Help With All Your Homebrew Setup Needs

Whether you need a trigger handle butterfly valve or a pull handle butterfly valve, we’ve got you covered. And we also carry a full line of other sanitary fittings for creating the custom homebrew setup of your dreams.

Order your sanitary tri-clamp valves and other fittings today. Your next brew day will be easier and shorter, getting you to that cold one sooner.