The Seven Types of Brewery Hose Materials

Brewery hoses serve an incredible function throughout the brewing process. From transferring between tanks, to cleaning and even distribution systems. However, there is rarely one type of hose material that meets all the needs of today’s breweries. What might work great for one application may not be the best selection for another. What follows is a list of the seven, most-common types of materials used for brewing along with a description of each based upon use cases.

- Chlorobutyl

- FDA UHMW

- PVC

- Silicone

- Nitrile

- EPDM

- PTFE (Teflon)

Chlorobutyl Hoses

The most common style of hose material found within brewery hoses. These types of hoses are considered compliant with 3A Sanitary Standards and are approved for the transferring of food & beverage by the FDA.

The ultra-smooth, microbe resistant tube is built for non-oily applications and is suitable for clean-in-place (CIP) procedures.

Chlorobutyl Transfer Brewery Hose

Additional Features:

- Temp. Range: -40°F to 225°F

- Working Pressure: 250PSI

- Ultra smooth inner bore

- Abrasion resistant

- Chemical and ozone resistant

- Will not impart taste or odor

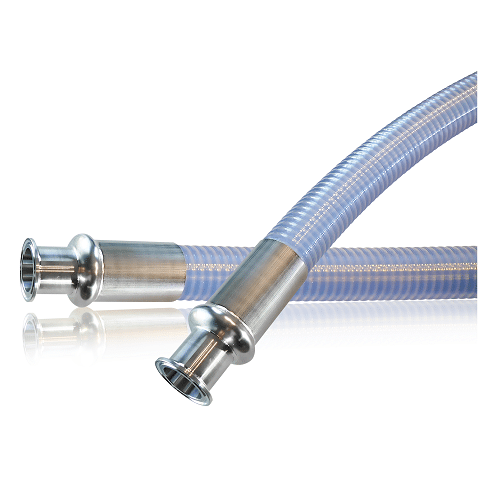

FDA UHMW Hoses

The UHMW hose is recommended for special applications that require smooth tubes and easy to clean surfaces. UHMW is odorless and tasteless for all those all purpose transfer applications. This ultra smooth microbe resistant tube is built on special stainless steel mandrels for cleanliness.

Food & Transfer UHMW Brewery Hose

Additional Features:

- Temp. Range: -40°F to 225°F. (CIP to 248°F. Not for continuous steam service)

- Working Pressure: 200PSI

- Ultra smooth inner bore

- Will not impart taste or odor

PVC Hoses

PVC hoses are typically used in breweries for either filling water tanks, CO2 lines or blow off applications. Given their lower temperature ratings, PVC hoses serve more of an ancillary purpose.

Additional Features:

- Temp. Range: -25°F to 150°F

- Working Pressure: 70PSI depending upon temperature

- Food & Beverage Dispensing

- Air & Water Supply Lines

- Clear for additional visibility

Silicone Hoses

This type of hose/tubing is usually used for running tap lines or small batch transfers. A higher-temperature version of this hose material is available for extended temperature ranges. This type of hose material is also one of the most flexible making is ideal for tight spaces.

Clear Silicone Transfer Hose

Additional Features:

- Temp. Range: -100°F to 350°F

- Ultra flexible

- For use with autoclave and CIP processes

- Will not impart taste or odor

- Non-toxic, Non-pyrogenic

Nitrile Hoses

This material is excellent for oily transfers, however, the most common application in breweries would be for Washdown hoses.

Washdown Brewery Nitrile Hose

Additional Features:

- Temp. Range: -13°F to 176°F

- Working Pressure: 200PSI

- Flexible material

EPDM Hoses

Designed with improved chemical and temperature resistance capabilities for wine, beer and beverage production. EPDM hoses offer higher chemical and temperature resilience; increased strength and hardness that facilitate better coupling retention at elevated temperature; and enhanced abrasion and ozone resistance.

Standard EPDM Vintner Hose

Additional Features:

- Temp. Range: -30°F to 220°F

- Working Pressure: 250PSI

- Extensive chemical compatibility

PTFE (Teflon) Hoses

The most chemical-resistant material, Teflon hoses would typically be used for caustic dosing stations and distribution systems. Given the higher temperature ranges, this hose is also commonly used with steam applications.

Additional Features:

- Wide Temperature Compatibility

- Chemical Resistance

- Steam Compatibility